FOR SERVICE TECHNICIAN’S USE ONLY

PART NO. W10054150

TECH SHEET - DO NOT DISCARD

PAGE 10

➔

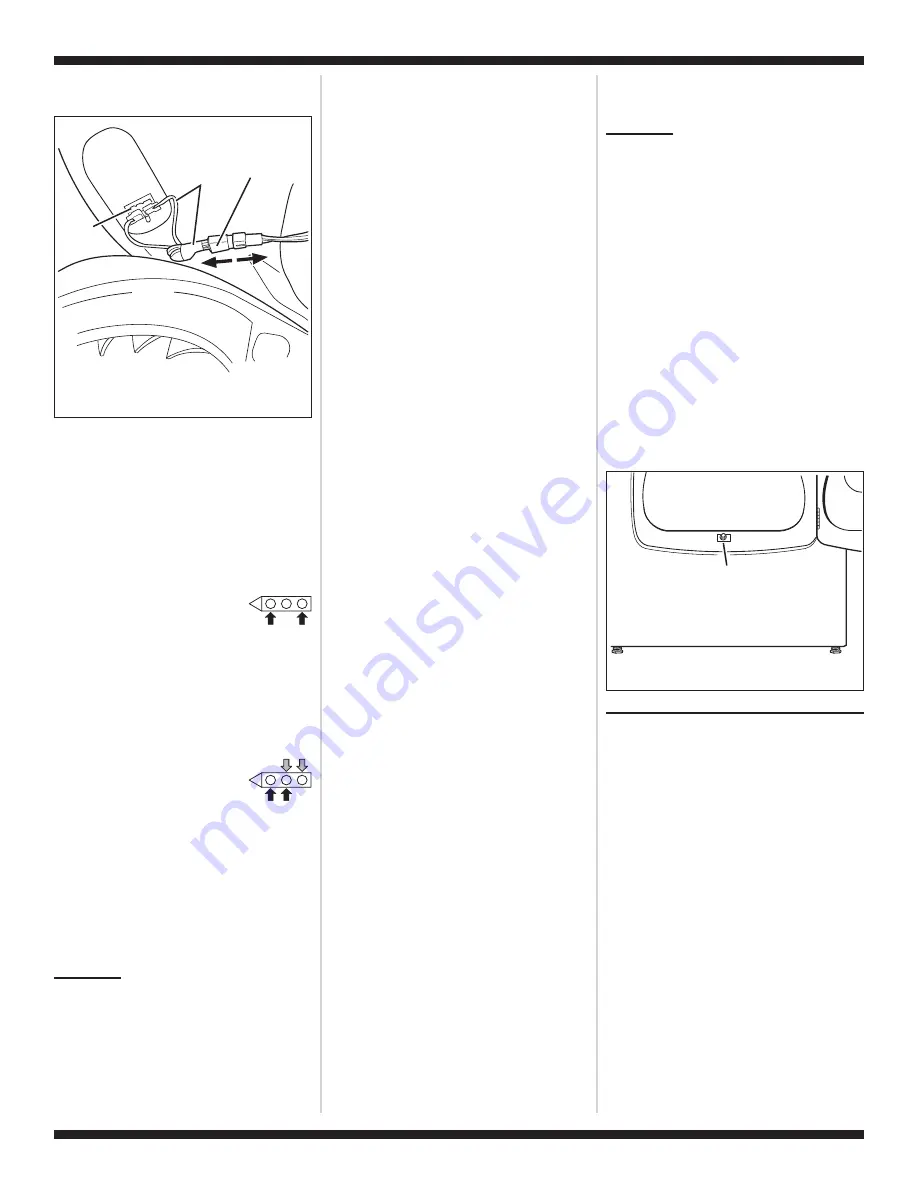

Disconnect the sensor connector. See

figure 10.

5.

Access the machine control electronics.

See Accessing & Removing the

Electronic Assemblies, page 11. Remove

the connector P13 from the circuit board.

Check the main harness connections

between the sensor connector and

machine control for a short or open

circuit.

➔

Replace the main harness if necessary.

➔

If harness is OK, continue with step 6.

6.

Measure the resistance

across the outermost

contacts of the sensor

connector that includes the two MOVs.

➔

If a small resistance is measured,

check for debris across moisture strips

inside of the drum; clean if debris is

present. If debris is not present,

replace sensor harness with MOVs.

➔

Otherwise go to step 7.

7.

Measure the resistance across

each of the outermost

contacts and the center

terminal (ground connection).

➔

If a resistance less than infinity is

measured, replace the sensor harness

with MOVs.

8.

If moisture sensor diagnostic test passes,

check the thermistor: Perform TEST #4a,

page 8.

➔

If the problem persists after replacing

the moisture sensor, harness with

MOVs and thermistor, replace the

machine control electronics.

TEST #6

Buttons and

Indicators

This test is performed when any of the

following situations occurs during the

Console Buttons and Indicators Diagnostic

Test, page 1:

✔

None of the indicators light up

✔

No beep sound is heard

✔

Some buttons do not light indicators

None of the indicators light up:

1.

See Diagnostic Guide/Before Servicing...

on page 1.

2.

Perform TEST #1, page 6 to verify supply

connections.

3.

Perform TEST #2, page 6.

4.

Perform steps in Accessing & Removing

the Electronic Assemblies, page 11 and

visually check that the P5 connector is

inserted all the way into the machine

control electronics.

5.

Visually check the user interface

assembly connections.

6.

If both visual checks pass, replace the

user interface assembly.

7.

Plug in dryer or reconnect power.

8.

Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

9.

If indicators still do not light, the machine

control electronics has failed:

➔

Unplug dryer or disconnect power.

➔

Replace the machine control

electronics.

➔

Plug in dryer or reconnect power.

➔

Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

No beep sound is heard:

1.

Perform steps in Accessing & Removing

the Electronic Assemblies, page 11 and

visually check that the P5 connector is

inserted all the way into the machine

control electronics.

➔

If visual check passes, replace the user

interface assembly.

2.

Plug in dryer or reconnect power.

3.

Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

4.

If replacing the user interface assembly

failed:

➔

Unplug dryer or disconnect power.

➔

Replace the machine control

electronics.

➔

Plug in dryer or reconnect power.

➔

Perform the Console Buttons and

Indicators Diagnostic test, page 1

to verify repair.

Some buttons do not light indicators:

1.

Perform steps in Accessing & Removing

the Electronic Assemblies, page 11 and

visually check the user interface

assembly connections.

➔

If visual check passes, replace the user

interface assembly.

2.

Plug in dryer or reconnect power.

3.

Perform the Console Buttons and

Indicators Diagnostics test, page 1 to

verify repair.

TEST #7

Door Switch

Activate the diagnostic test mode as shown

on page 1, and perform the Door Switch

Diagnostic test, page 1. Functionality is

verified with a beep each time the door is

closed and opened, and a number and letter

appears in the display (i.e.,

0E

,

09

).

If any of these conditions are not met:

➔

Unplug dryer or disconnect power.

➔

Check that the wires between the door

switch and machine control electronics

are connected. See figure 11 for switch

location and see Removing the Front

Panel/Drum Assembly, page 11.

➔

If the connections are OK, replace the

door switch assembly and retest.

➔

If the door switch assembly has been

replaced and dryer still does not start,

replace the machine control

electronics.

ADJUSTING CUSTOMER-

FOCUSED DRYING MODES

NOTE:

If the customer is complaining about

the clothes being damp and the moisture

sensor passes TEST #5, page 9, step 3, the

total dry time for an automatic cycle can be

lengthened by changing from a “1” (standard

auto cycle) to a “2” (15% more drying time)

or “3” (20% more drying time) auto cycle.

1.

Press and hold the Dryness button for 5

seconds. The dryer will beep and display

CF

for one second, then the current

drying mode will be seen on the display.

The factory default value is “1”.

2.

To select a different drying mode, press

the Dryness button again. The dryer

display will flash and show the available

settings.

3.

With the display flashing the selected

drying mode, press the Start button to

save the drying mode and exit (the Start

button in this mode does not start a

drying cycle). The result will be stored in

EEPROM of the control board, and will be

retained after a power loss.

Door Switch

Figure 11.

Door switch location.

Sensor Harness

with MOVs

(Metal Oxide

Varistors)

Sensor

Connector

Sensor

Blower

Housing

Figure 10.

Disconnect sensor

connector.