3

Service and Maintenance

• Rinse all parts with clean water before reassembly.

• Do not use any pipe dope, oil, grease, or solvent on any parts

unless instructed to do so.

• Do not force parts. Parts should fit together freely. Excess force

can cause damage and render the assembly inoperable.

• Carefully inspect seals and seating surfaces for debris or damage.

• After servicing, repressurize the assembly and test to ensure

proper operation.

For more information on maintenance, check with your FEBCO

representative or go to FEBCOonline.com.

Check Valve Disassembly

1. Close the outlet shutoff valve, then close the inlet shutoff valve.

Bleed residual pressure from the assembly by opening test

cocks No. 4, No. 3, and No. 2 in this sequence.

2. Remove the cover nuts and bolts and lift the cover from

the body. The springs are retained and the cover should be

pushed away from the body approximately 1/4 inch.

3. Inspect the parts and debris from the disc and seat ring.

Replace worn or damaged parts as required.

4. Replace the cover, making sure the spring assembly is

positioned in the pivot socket. If necessary, apply FDA

Approved grease to the O-ring groove in the body to keep

the O-ring in position while installing the cover.

5. Install the bolts and nuts and tighten.

PROBLEM

CAUSE

SOLUTION

Continuous relief valve discharge

Debris on check seating surfaces

Disassemble and clean

Debris on relief valve surfaces

Intermittent relief valve discharge

Inlet pressure fluctuations

Eliminate fluctuations

Downstream pressure surges

Eliminate surges

Low flows passing through mainline valve (RPDA)

Mainline check fouled

Disassemble and clean

Troubleshooting

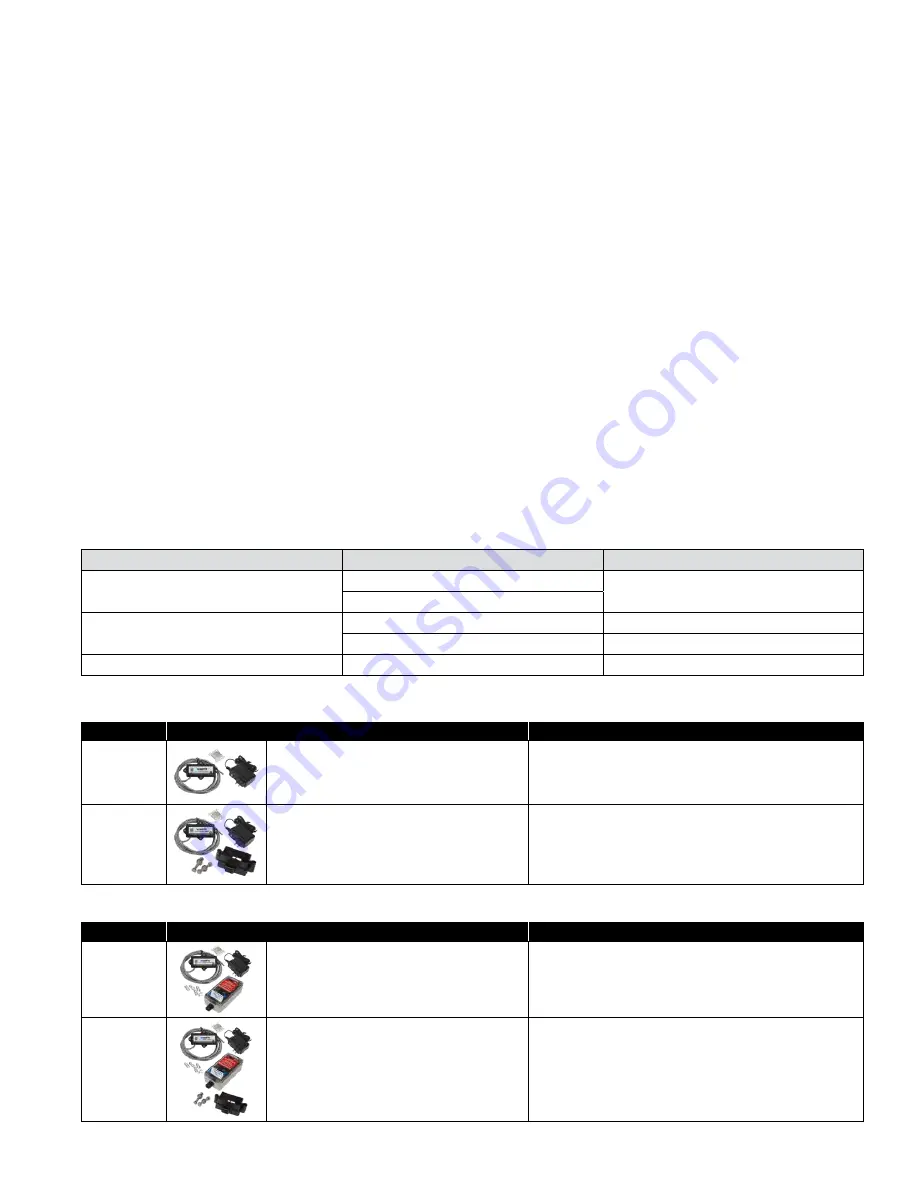

Add-on and Retrofit Sensor Connection Kits for Building Management Systems

ORDERING CODE

ADD-ON/RETROFIT KIT

DESCRIPTION

88009414

FP-FBF-BMS-21/2-10

BMS Sensor Connection Kit

Series LF860 Large, LF866, LF880V, LF886V

Sizes 2½" to 10"

Includes sensor activation module with cable, ground wire, and power

adapter. Use this kit to activate the flood sensor and enable flood detection

capabilities on the relief valve of a new installation linked to a BMS controller

(not included).

88009415

FP-RFK-FBF-BMS-CFS-21/2-10

BMS Sensor Retrofit Connection Kit

Series LF860 Large, LF866, LF880V, LF886V

Sizes 2½" to 10"

Includes flood sensor with mounting hardware, sensor activation module

with cable, ground wire, and power adapter. Use this kit to install the flood

sensor and enable flood detection capabilities on the relief valve of an exist-

ing installation linked to a BMS controller (not included).

Add-on and Retrofit Sensor Connection Kits for Cellular Communication

ORDERING CODE

ADD-ON/RETROFIT KIT

DESCRIPTION

88009416

FP-FBF-CFS-21/2-10

Cellular Sensor Connection Kit

Series LF860 Large, LF866, LF880V, LF886V

Sizes 2½" to 10"

Includes sensor activation module with cable, Cellular Gateway with mount-

ing kit, ground wire, and power adapter. Use this kit to activate the flood

sensor and enable flood detection capabilities on the relief valve of a new

installation linked to a cellular network to send alerts by email message,

SMS text message, or voice call.

88009417

FP-RFK-FBF-CFS-21/2-10

Cellular Sensor Retrofit Connection Kit

Series LF860 Large, LF866, LF880V, LF886V

Sizes 2½" to 10"

Includes flood sensor with mounting hardware, sensor activation module

with cable, Cellular Gateway with mounting kit, ground wire, and power

adapter. Use this kit to install the flood sensor and enable flood detection

capabilities on the relief valve of an existing installation linked to a cellular

network to send alerts by email message, SMS text message, or voice call.

Relief Valve Disassembly

1. Detach the activation module, if installed, from the flood sensor.

2. Use two ½" wrenches to remove the sensor from the relief valve.

3. Remove the cap screws holding the cover to the relief valve

body, and remove the cover.

4. Remove the diaphragm and pull the internal assembly from

the body. If helpful, push the internal assembly with fingers

through the discharge opening.

5. Inspect for debris, damage, or fouling of the seat disc. Clean

or replace parts as required.

6. Reassemble in the reverse order of disassembly.

Test Procedure for Reduced Pressure Assemblies

Check the ASSE Series 5000 manual for an appropriate test

method that is consistent with local codes of the area.