7

IOM-A-Deringer 40/40X/50/50X_6-8

2005

EDP#2916006

© 2020 Watts

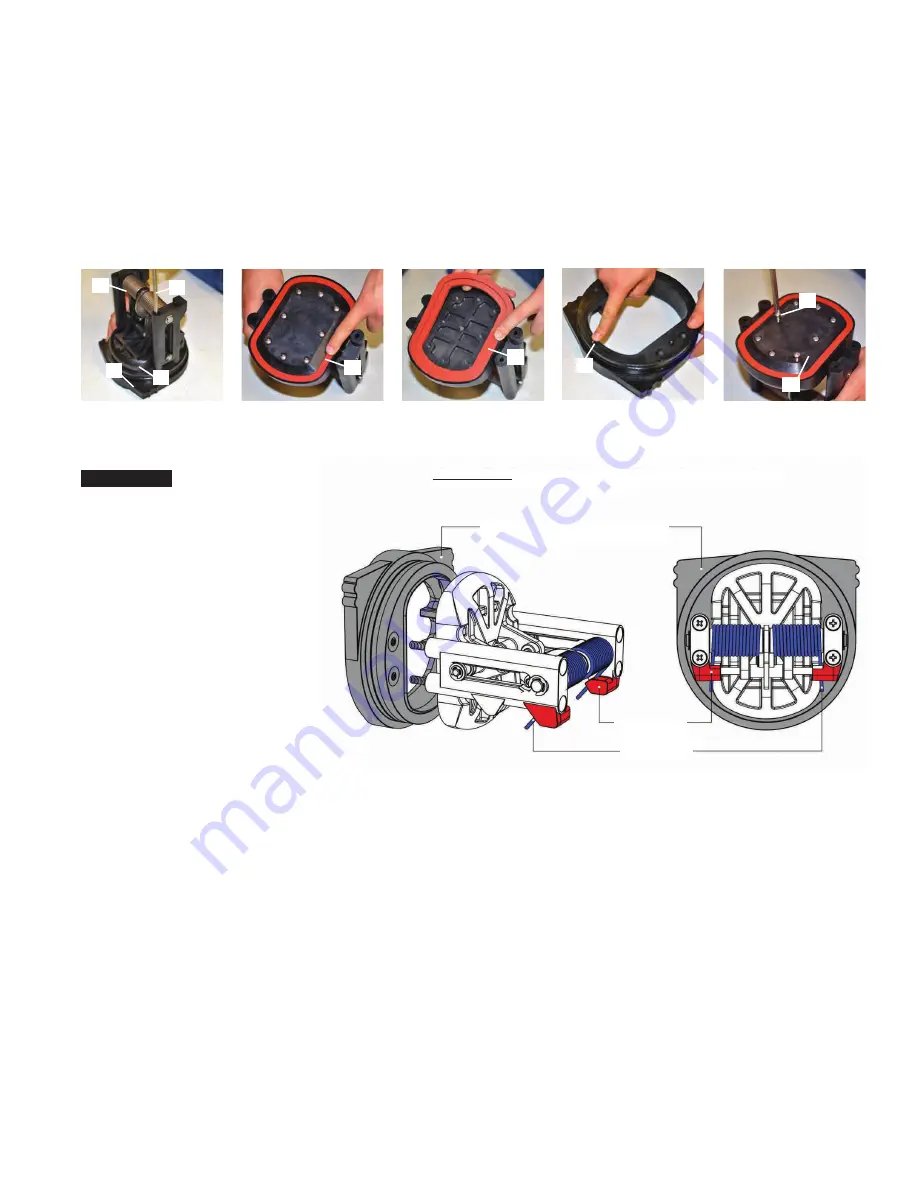

Maintenance of Second Dual-action Check Module

1. Use a #2 phillips head screwdriver to remove tower screws

(A) from the second check seat (B) the double torsion

spring is captured (C) and does not to be retained

during maintenance.

2. After removing the tower screws (A) examine the elastomer

disk (D) and check seat (E) for fouling or damage.

3. Should elastomer disk (D) need replacement unscrew disk

retainer screws (F) and remove disk retainer (G). Carefully

remove and replace elastomer disk (D). When replacing

elastomer disk (D) be certain that no air, water or debris is

trapped in the clapper (H) cavity behind the elastomer disk (D).

4. Reverse the order of the above instructions to reassemble check.

• Elastomer disk must be flat in clapper (H) cavity before

tightening disk retainer screws (F).

• Do not cross thread disk retaining screws (F).

F

G

D

H

B

C

A

E

D

NOTICE

Second Check Tower Bosses and Spring Arms Face Down

Orient seat protrusions as shown

Tower Bosses

Spring Arms

The diagram on the right shows the correct orientation of the

second dual-action check module when being re-attached to

the seat. In order to maintain the performance of the valve pay

attention to the proper orientation of the check module.