Introduction

Welcome to the M

INI

C

HEF

2000™

The M

INI

C

HEF

2000 is a configurable, time/temperature and machine function controller

that is preprogrammed for dozens of cooking applications. Its compact size and optional

horizontal/vertical orientation facilitates streamlined equipment design. It withstands

rigorous application environment conditions, with an 80ºC ambient rating and superior

EMI/RFI immunity. It is also backed by Watlow’s exclusive three-year warranty.

Each unit is equipped to offer:

•

two temperature sensor inputs

•

two event inputs (for machine control)

•

two heat control outputs

•

two event outputs (for machine control)

•

one audible alarm output

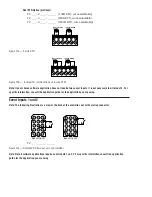

(See diagram below.)

Depending on the application software you select, some or all of the inputs or outputs

are used. See the Application Selection Table that follows.

Figure 2 — Inputs and outputs.

See panel 23 for information about ordering

The

Complete M

INI

C

HEF

2000 User Manual.

A

B

D

E

C

F

G

H

4 Inputs

Input 1

Thermocouple or RTD

Input 2

Thermocouple or RTD

Event Input 1

Event Input 2

5 Outputs

Output 1

Switched DC or Solid-state Relay

Output 2

Switched DC or Solid-state Relay

Output 3

Event Output 1

Output 4

Event Output 2

Output 5

Audible Alarm Output

Содержание MINICHEF 2000

Страница 17: ...17 NOTES...

Страница 21: ...21 NOTES...