I. Methods for Compressor Maintenance

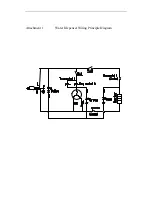

1. The single hermetic compressor has three terminals on the body:

R

•

primary coil or moving coil

t

.

.

S

•

starting coil

C

•

public poin

2. Judgment of compressor exhaust pipe oil vent

Generally, little oil discharges from a hermetic compressor. If oil is found to drip from the exhaust

pipe continuously, it is shown that the compressor is discharging too much oil. Over oil discharge

is mainly because that the clearance between cylinder and piston exceeds more than 1.5 times the

stipulated maximum fit clearance. In this case, disassemble the compressor, and inspect the fit

clearance between cylinder and piston. If it is out-of-tolerance, utilize a new piston.

II. Judgment of Compressor Electrical Machine Burning

1.

Winding turnoff

detect the three- winding by using an ohmmeter or a multimeter. If the

resistance between any two windings is infinite, turnoff happens.

2.

Winding earthing

with a multimeter (at low resistance level), measure between the three

terminals from the hermetic compressor and the copper pipes out of the body respectively. If the

resistance between any one of the terminals and the ground is zero, the winding is short-circuited

3.

Winding short

with an ohmmeter or a multimeter, measure the insulation resistance between

any two windings. If the insulation resistance is too low, the windings are short-circuited

III. Compressor Shaft Seizing and Cylinder Blocking

Compressor shaft seizing and cylinder blocking mean that broken-in surfaces of moving parts hug

each other and can no longer run, which are caused by bad lubricating parts, oil cut-off or blocked oil

circuits.

Troubleshooting: disassemble the compressor to determine where the failure takes place. In the

case of shaft seizing, knock on the seized surface or counterbalance with a wood stick or a copper rod.