Attachment 3

Compressor Working Principle and Failure Analysis

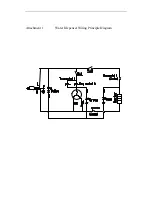

Brief outline of compressor cooling working principle

The water dispenser compressor cooling system mainly includes compressor, condenser, filter,

evaporator, capillary and other components.

The water dispenser adopts a rotary compressor filled with cool-producing medium R134a.

R134a gas is, by the compressor, compressed into high-pressure gas, goes into the condenser and then

becomes high-pressure liquid. After being filtered by the drying filter, the liquid has its pressure

reduced through the capillary, and then enters the evaporator. Because the evaporator has much larger

volume than that of the capillary, liquid freon will absorb a great deal of heat from outside to become

gas, and finally returns to the compressor, forming the closed circulatory system.

Compressor common failures and their maintenance methods

Because the compressor and electrical machine are both sealed, there are a suction pipe and a exhaust

pipe but no cut-off valve on the body, and capillary throttle is utilized, the compressor may also fail to

work or cause the electrical machine to be burned when the electrical machine’s cooling conditions

become worse or failures happen in the system. Below are some methods for judgment and

maintenance of common compressor failures.

Drying filter

Capillary

Evaporator

Condenser

Compressor