BX36S

3PH Self-feed Chipper

Operation

29

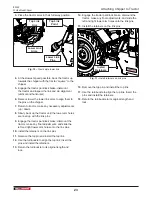

12.6 Starting Procedure

After following all operating safety and preparation

procedures, the chipper is now ready to operate.

1.

Ensure all the chipper access covers are secured

2.

Inspect hydraulic connectors for positive

connection.

3.

Start tractor and engage the PTO.

4.

Increase engine speed to approximately half

throttle.

5.

Ensure machine is stable, with no unusual

vibration and proceed with work.

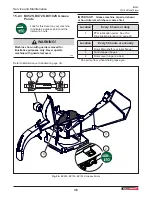

12.7 Stopping

CAUTION!

Be aware. Rotor continues to turn for a few

revolutions after the PTO is disengaged. Wait

for all parts to stop moving before opening any

machine access.

W005

1.

Stop feeding material into the hopper.

2.

Place the feed control bar in neutral position.

3.

Slow engine speed.

4.

Place tractor hydraulic lever in OFF position.

5.

Disengage PTO.

6.

Stop engine, remove ignition key and place in your

pocket. Wait for all moving parts to stop.

12.8 Stopping in an Emergency

If an emergency occurs:

• Activate the emergency PTO shutoff on the

tractor (if available) or disengage the PTO

• Shut off the engine

• Correct emergency situation before restarting

engine and resuming work.

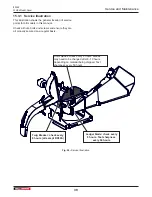

12.9 Chipping Operation

BX Series Wood Chippers are strong, rugged

machines. They are built to provide consistent chipping

of logs.

CAUTION!

Be aware. Rotor continues to turn for a few

revolutions after the PTO is disengaged. Wait

for all parts to stop moving before opening any

machine access.

W005

Material size capacity

•

BX36S – 3.5" (9 cm) diameter

•

BX52S – 5" (13 cm) diameter

•

BX72S – 7" (17 cm) diameter

•

BX102S – 10" (25 cm) diameter

IMPORTANT! Do not place metal, bottles, cans,

rocks, glass or other solid material into the

wood chipper. If that happens, stop the machine

immediately for a detailed inspection.

If opening up any guards for inspection, always put the

machine in

Safe Condition

. See

Inspect machine for damaged or loosened parts.

Repair or replace parts as required before resuming

work.

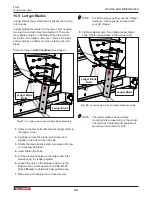

1.

Delimb large branches and trees and feed them in

ONE

at a time.

2.

Be aware of the size and shape of the material.

Knotty, curved branches and logs can move in

unpredictable ways as they pass through the

feed rollers. Large curved pieces should be cut to

smaller straighter sections.

3.

Very small diameter branches / limbs can be held

together in a bundle and feed in simultaneously.

4.

Place short branches on top of longer ones, to

avoid reaching into the hopper.

Содержание BX36S

Страница 1: ...OPERATOR S MANUAL 3PHSelf feedChipper BX36S BX52S BX72S BX102S...

Страница 51: ......

Страница 52: ...www wallensteinequipment com...