4

ProSpray 20

GB

1

GENERAL SAFETY INSTRUCTIONS

WARNING!

Read all safety information, instructions,

illustrations and technical data provided with

this power tool.

Failure to observe the following

instructions may cause electric shock, fire and/or

severe injuries.

Keep all safety information and

instructions for future reference.

The term “power

tool” used in this safety information refers to mains-

operated power tools (with power cable) and to

battery-powered power tools (without power cable).

1. Safety at the workplace

a) Keep your workplace clean and well lit.

Disorder or

unlit workplaces may result in accidents.

b) Do not work with the power tool in potentially

explosive environments where there are flammable

fluids, gases or dust.

Power tools generate sparks that

can ignite the dust or vapors.

c) Keep children and other persons away when using

the power tool.

If distracted, you may lose control of the

power tool.

2. Electrical Safety

a) The connection plug of the power tool must fit in the

socket. The plug may not be modified in any form.

Verwenden Sie keine Adapterstecker gemeinsam mit

schutzgeerdeten Elektrowerkzeugen.

Unmodified plugs

and suitable sockets reduce the risk of an electric shock.

b) Avoid physical contact with earthed surfaces such as

pipes, heating elements, stoves and refrigerators.

The

risk through electric shock increases if your body is earthed.

c) Keep power tools away from rain or moisture.

Water

penetrating into a power tool increases the risk of an electric

shock.

d) Do not misuse the power cord to carry the power tool,

hang up the power tool or pull the plug out of the

socket. Keep the power cord away from heat, oil, sharp

edges or moving parts.

Damaged or entangled power

cords increase the risk of an electric shock.

e) If the power tool must be used in a moist environment,

use a ground fault circuit interrupter.

Using a residual

current operated circuit-breaker avoids the risk of electric

shock.

3. Safety of Persons

a) Be attentive. Pay attention to what you are doing and

work sensibly with a power tool.

Do not use the power

tool if you are tired or under the influence of drugs,

alcohol or medication.

One moment of carelessness when

using the power tool may cause serious injuries.

b) Wear personal safety equipment and always wear

safety goggles

Wearing personal protective equipment,

such as dust mask, non-slip safety shoes, safety helm or ear

protection, depending on the type of power tools, reduces

the risk of injury.

c) Avoid accidental starting-up. Make sure that the power

tool is switched off before you connect it to the power

tool and/or battery, pick it up or carry it.

Accidents may

happen if you have your finger on the switch while carrying

the power tool or if the device is switched on when you

connect it to the power supply.

d) Remove setting tools or wrenches before switching

on the power tool.

A tool or key in a rotating part of the

power tool can cause injuries.

e) Avoid an unnatural posture. Ensure that you are

standing securely and have your balance at all

times.

This allows you can better control the power tool in

unexpected situations.

f) Wear suitable clothing. Do not wear wide clothing or

jewellery. Keep your hair, clothes and gloves away

from moving parts.

Loose clothing, jewellery or long hair

can be caught in moving parts.

g) Do not lull yourself into a false sense of security and

do not think yourself above the safety rules for electric

tools, even if you are familiar with the electric tool

following extensive practical experience.

Careless use

can lead to serious injuries in fractions of a second.

4. Usage and treatment of the electric tool

a) Do not overload the power tool. Use the power tool

designed for the work that you are doing.

You work

better and safer in the specified performance range if you

use the suitable power tool.

b) Do not use power tools whose switch is defective.

A

power tool that cannot be switched on or off is dangerous

and has to be repaired.

c) Disconnect the plug from the socket and/or take

out a removable battery before you make device

adjustments, change accessories or put the power tool

away.

This precautionary measure prevents the power tool

from starting unintentionally.

Содержание PROSPRAY 20

Страница 2: ......

Страница 13: ...13 ProSpray 20 GB...

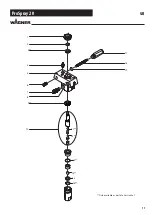

Страница 17: ...17 ProSpray 20 17 18 19 1 2 3 4 6 5 7 8 10 9 11 12 13 14 15 16 Only available as part of a Service Set GB...