5

ProSpray 20

GB

d) Store unused power tools so that they are inaccessible

to children. Do not let persons use the tool who

are not familiar with it or who have not read these

instructions.

Power tools are dangerous when they are used

by inexperienced persons.

e) Maintain the power tool and insertion tools with

care. Check whether moving device parts are working

flawlessly and are not jamming, whether parts are

broken or damaged so that as to impair the function

of the power tool. Have damaged parts repaired before

using the power tool.

Many accidents have their origin in

power tools that have been maintained badly.

f) Use the power tool, accessories, insert tools, etc. in

accordance with these instructions and in a fashion

specified for this special tool type. Take the working

conditions and the activity to be carried out into

consideration.

The use of power tools for purposes other

than the intended ones can lead to dangerous situations.

g) Keep the handles and grip surfaces dry, clean and free

of oil and grease.

Slippery handles and grip surfaces

hamper safe operation and control of the electric tool in

unforeseen situations.

5. Service

a) Only have your power tool repaired by a qualified

specialist and only use original spare parts.

This

ensures that the tool safety is maintained.

b) If the supply cord is damaged, it must be replaced

by the manufacturer or it’s service agent or a

similarly qualified person in order to avoid a safety

hazard.

2

SAFETY REGULATIONS FOR

AIRLESS SPRAYING

All local safety regulations in force must be observed.

The following safety regulations are to be observed in order to

ensure safe handling of the Airless high-pressure spraying unit.

2.1

FLASH POINT

Only spray coating materials with a flash point

of 21 °C or higher.

The flash point is the lowest temperature at

which vapors develop from the coating mate-

rial. These vapors are sufficient to form an in-

flammable mixture over the air above the coat-

ing material.

2.2

EXPLOSION PROTECTION

Do not use the unit in work places which are

covered by the explosion protection regula-

tions. The unit is not designed to be explosion

protected. Do not operate the device in ex-

plosive areas (zone 0, 1 and 2). Explosive ar-

eas are, for example, places where paints are

stored and locations in direct proximity to the

object being sprayed. Keep the device at least

3 m from the object you are spraying.

2.3

DANGER OF EXPLOSION AND FIRE FROM

SOURCES OF IGNITION DURING SPRAYING

WORK

There must be no sources of ignition such as,

for example, open fires, lit cigarettes, cigars or

tobacco pipes, sparks, glowing wires, hot sur-

faces, etc. in the vicinity.

2.4

DANGER OF INJURY FROM THE SPRAY JET

Attention, danger of injury by injection!

Never point the spray gun at yourself, other

persons or animals.

Only use the spray gun with spray jet touch

protection.

The spray jet must not come into contact

with any part of the body.

In working with Airless spray guns, the high

spray pressures arising can cause very dan-

gerous injuries. If contact is made with the

spray jet, coating material can be injected

into the skin. Do not treat a spray injury as a

harmless cut. In case of injury to the skin by

coating material or solvents, consult a doctor

for quick and correct treatment. Inform the

doctor about the coating material or solvent

used.

2.5

SECURE SPRAY GUN AGAINST UNINTENDED

OPERATION

Always secure the spray gun when mounting or dismounting

the tip and in case of interruption to work.

2.6

RECOIL OF SPRAY GUN

When using a high operating pressure, pull-

ing the trigger guard can effect a recoil force

up to 15 N.

If you are not prepared for this, your hand can

be thrust backwards or your balance lost. This

can lead to injury.

Содержание PROSPRAY 20

Страница 2: ......

Страница 13: ...13 ProSpray 20 GB...

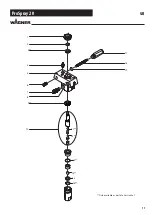

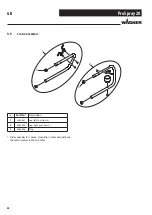

Страница 17: ...17 ProSpray 20 17 18 19 1 2 3 4 6 5 7 8 10 9 11 12 13 14 15 16 Only available as part of a Service Set GB...