36

PEM-X1

OPERATING MANUAL

VERSION 09/2012

ORDER NUMBER DOC 2326020

The maintenance intervals should be adapted by the operator depending on the level of

use and if necessary the level of soiling.

In doubt, we recommend to contact J. Wagner AG's specialist personnel.

The valid health and safety specifi cations and safety instructions provided in chapter 4

must be adhered to for all maintenance work.

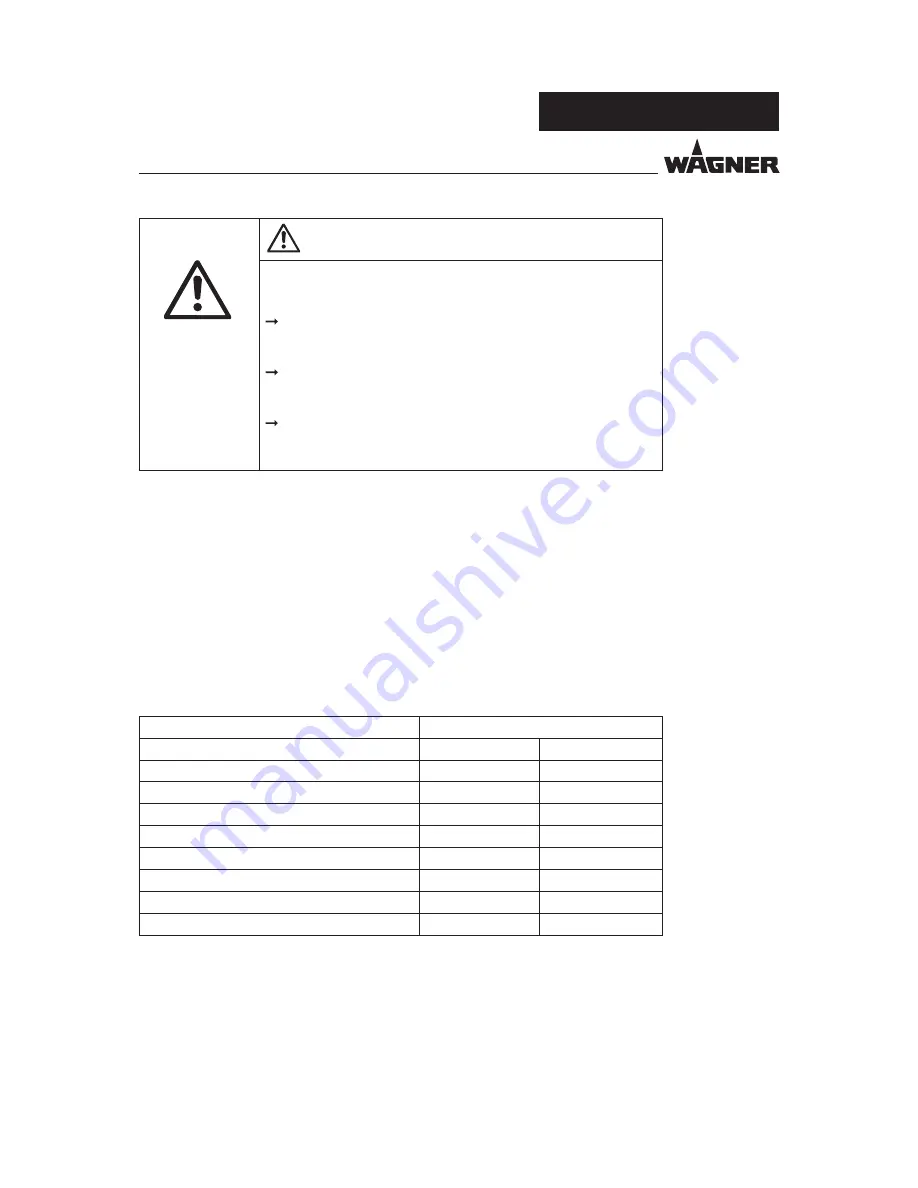

Maintenance work

Point in time

per shift

weekly

Blow out gun and check for sintering

x

Check gun settings

x

Check gun discharge pressure

x

Blow out powder hoses

x

Check grounding

x

Check compressed air quality

x

Check gun voltage

x

Check powder hoses for bends and sintering

x

8.2.3

MAINTENANCE PROCEDURES

Incorrect maintenance!

Risk of injury and damage to the equipment.

If contact with powder materials or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g. wearing protective clothing.

The footwear worn by operating staff must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100 MΩ (megaohms).

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 MΩ (megaohms).

WARNING

Содержание PEM-X1

Страница 2: ......

Страница 65: ...65 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020 14 4 EC TYPE EXAMINATION CERTIFICATE...

Страница 66: ...66 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020...

Страница 67: ...67 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020...

Страница 68: ...68 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020 14 5 FM APPROVAL in submission...

Страница 69: ...69 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020...

Страница 71: ......