28

PEM-X1

OPERATING MANUAL

VERSION 09/2012

ORDER NUMBER DOC 2326020

Procedure:

1.

Switch on the high-voltage generation and the powder feed.

Note:

To minimize wear on the wearing parts, the total air volume should be below 5 Nm³/h!

The atomizing air should be adjusted for the

fl at spray nozzle to 0.1 Nm³/h

round spray nozzle to > 0.2 Nm³/h

2.

Adjust the powder quantity and the powder speed on a test piece.

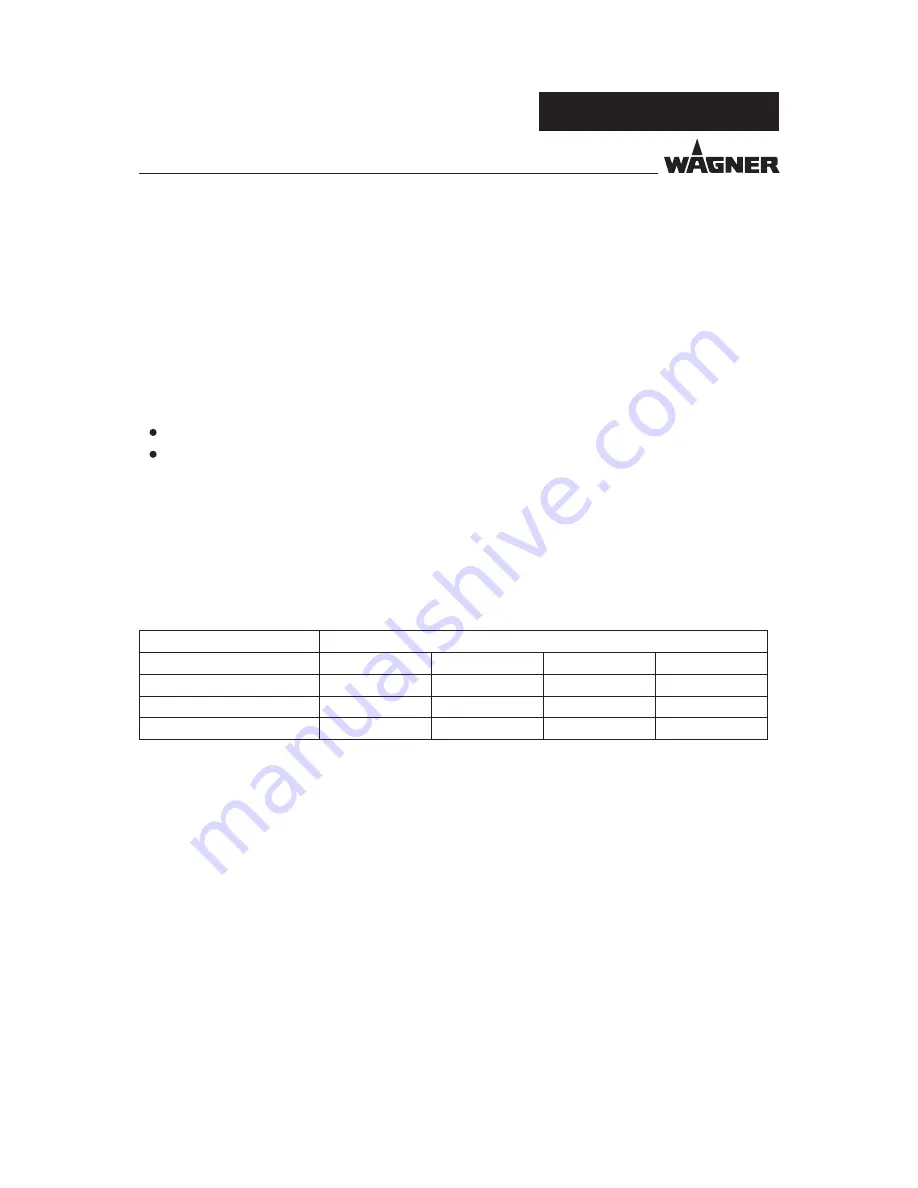

7.3

OPTIMIZING THE POWDER CLOUD FOR COATING

7.3.1

RECOMMENDED SETTINGS FOR TOTAL AIR VOLUME

Hose diameter

Hose length

9 mm

10 mm

11 mm

12 mm

4 - 8 m

2.0 - 2.5 m³/h

3.0 - 3.5 m³/h

4.0 - 4.5 m³/h

8 - 12 m

2.5 - 3.0 m³/h

3.5 - 4.0 m³/h

4.5 - 5.0 m³/h

12 - 16 m

3.0 - 3.5 m³/h

4.0 - 4.5 m³/h

5.0 - 5.5 m³/h

Содержание PEM-X1

Страница 2: ......

Страница 65: ...65 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020 14 4 EC TYPE EXAMINATION CERTIFICATE...

Страница 66: ...66 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020...

Страница 67: ...67 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020...

Страница 68: ...68 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020 14 5 FM APPROVAL in submission...

Страница 69: ...69 PEM X1 OPERATING MANUAL VERSION 09 2012 ORDER NUMBER DOC 2326020...

Страница 71: ......