6

© Wagner. All rights reserved.

R

GB

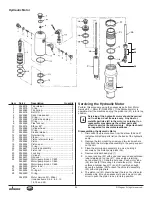

Preparing a New Sprayer

If this sprayer is new, it is shipped with test fluid in the fluid

section to prevent corrosion during shipment and storage. This

fluid must be thoroughly cleaned out of the system with mineral

spirits before you begin spraying.

Attention

Always keep the trigger lock on the spray gun in

the locked position while preparing the system.

1. Place the siphon hose into a container of mineral spirits.

2. Place the bleed hose into a metal waste container.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

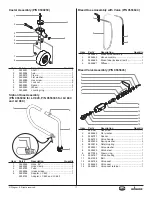

Bleed Valve

Hydraulic Shut-off

Valve (in closed

position)

Pressure

Control Knob

4. Open the hydraulic shut-off valve located on the hydraulic

pressure hose. The handle should be in line with the

hose.

5. Open the bleed valve by turning it fully counterclockwise.

6. Start the engine.

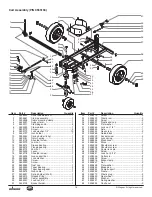

Fuel Valve

Lever

Choke Lever

Engine

Switch

Throttle

Lever

Starter Rope

a. To start the gas

engine,

• move the fuel valve

lever to the open

position,

• move the throttle

lever to its middle

point,

• move the choke

lever to the closed

position for a cold

engine or to the open position for a warm engine,

• turn the engine switch to the ON position, and

• pull the starter rope briskly until the engine starts.

7. Turn the pressure control knob clockwise approximately

1/3 of the way down to increase pressure until the sprayer

cycles evenly and solvent flows freely from the bleed

hose.

8. Allow the sprayer to run for 15–30 seconds to flush the

test fluid out through the bleed hose and into the waste

container.

9. Turn off the sprayer.

a. To turn off the gas engine,

• set the pressure to minimum by turning the pressure

control knob fully counterclockwise,

• move the throttle lever to the slow position, and

• turn the engine switch to the OFF position.

Preparing to Paint

Before painting, it is important to make sure that the fluid in the

system is compatible with the paint that is going to be used.

i

Incompatible fluids and paint may cause the valves

to become stuck closed, which would require

disassembly and cleaning of the sprayer’s fluid

section.

Attention

Always keep the trigger lock on the spray gun in

the locked position while preparing the system.

1. Place the siphon hose into a container of the appropriate

solvent.

i

If you are spraying a water-based latex, flush with

warm, clean water. If you are using any other

material, check with the material manufacturer for a

compatible solvent.

2. Place the bleed hose into a metal waste container.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

4. Open the hydraulic shut-off valve located on the hydraulic

pressure hose. The handle should be in line with the

hose.

5. Open the bleed valve by turning it fully counterclockwise.

6. Start the engine.

a. To start the gas engine,

• move the fuel valve lever to the open position,

• move the throttle lever to its middle point,

• move the choke lever to the closed position for a cold

engine or to the open position for a warm engine,

• turn the engine switch to the ON position, and

• pull the starter rope briskly until the engine starts.

7. Turn the pressure control knob clockwise approximately

1/3 of the way down to increase pressure until the

sprayer cycles evenly and solvent flows freely from the

bleed hose.

8. Allow the sprayer to run for 15–30 seconds to flush

the fluid out through the bleed hose and into the waste

container.

9. Turn off the sprayer.

a. To turn off the gas engine,

• set the pressure to minimum by turning the pressure

control knob fully counterclockwise,

• move the throttle lever to the slow position, and

• turn the engine switch to the OFF position.

i

Make sure that the spray gun does not have a tip or

tip guard installed.

10. Close the bleed valve by turning it fully clockwise.

11. Start the engine.

12. Turn the pressure control knob clockwise approximately

1/3 of the way down to increase pressure.

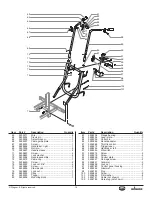

13. Unlock the gun by turning the gun trigger lock to the

unlocked position.

Danger

Earth the gun by holding it against

the edge of the metal container

while flushing. Failure to do so may

lead to a static electric discharge,

which may cause a fire.

Trigger lock

in locked position.

14. Trigger the gun into the metal waste

container until the old solvent is gone and

fresh solvent is coming out of the gun.

15. Lock the gun by turning the gun trigger

lock to the locked position.

16. Set down the gun and increase the

pressure by turning the pressure control

knob slowly clockwise.

17. Check the entire system for leaks. If leaks occur, follow

the “Pressure Relief Procedure” in this manual before

tightening any fittings or hoses.

18. Follow the “Pressure Relief Procedure” in this manual

before changing from solvent to paint.

Danger

Be sure to follow the pressure relief procedure

when shutting the sprayer down for any purpose,

including servicing or adjusting any part of the

spray system, changing or cleaning spray tips, or

preparing for cleanup.