36

VERSION 05/2018

ORDER NUMBER DOC 2312956

GA 4000ACIC

7

OPERATION

7.1

TRAINING THE OPERATING PERSONNEL

The operating personnel must be qualified to operate the entire system.

The operating personnel must be familiar with the potential risks associated with

improper behavior as well as the necessary protective devices and measures.

Before work commences, the operating personnel must receive appropriate system

training.

7.2

TASKS

CAUTION

Spurting out of liquids with high pressure!

Risk of injury and damage to the device.

No persons should be located in the hazard area during operation.

Make sure to keep a safe distance during setting up, installation and maintenance

work.

Ensure that:

The regular safety checks are carried out in accordance with Chapter

,

commissioning is carried out in accordance with Chapter

.

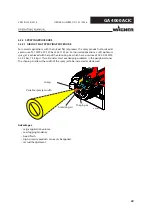

7.2.1 STARTING TO SPRAY WITH THE AIRCOAT

1. Set product supply to operating pressure of approx. 8 MPa; 80 bar; 1160 psi and start

up.

2. Spray (release control air) and check the atomization.

3. Set the spray pressure on the product supply such that optimum product atomization

is attained.

4. Open air pressure regulator for atomizing air and set.

5. Adjust the amount of air at the shaping air throttle until the optimum spray pattern

is reached.

The relation between the spray pattern and shaping is shown in the illustration below.

Note:

Repeat points 4 and 5 until the optimum spray pattern is reached (iterative process).

Содержание GA 4000ACIC-S

Страница 1: ...Version 05 2018 GA 4000ACIC S GA 4000ACIC R AirCoat Automatic spray gun II 2G X B_06647...

Страница 2: ......

Страница 66: ......

Страница 67: ......