Subject to modifications, errors excepted · © Wagner Solar GmbH, 2017 · www wagner-solar com

8

Wagner Solar GmbH · Sonnenallee 2 · D-35274 Ki49 6421 80 07-0

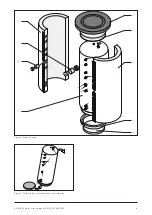

Figure 12 Insulation of the pipes

mA

●

Insulate pipes: continue pipe insulation into the re-

spective openings in the ratchet closure to avoid heat

loss at the entering points (fig 12)

6 Troubleshooting

The flat sealing gaskets may change their density during

the first few months of operation This normal settling

behavior may occasionally lead to dripping The connec-

tions should therefore re-tightened as required

7 Maintenance

The cleaning and maintenance of the solar storage tank

should be carried out every two years together with the

maintenance of the solar installation We recommend a

service contract

●

Defunct protective anode leads to corrosion of the

storage

tank!

Over time the built-in protective sacrificial anode is con-

sumed during operation Check the protective anode af-

ter two years, and afterwards annually

- Remove the build in uninsulated sacrificial magne-

sium anode, examine remaining magnesium mass and,

if necessary, install new anode

- For sacrificial anodes with insulated installation (MG an-

odes) test the protective current between storage and

anode (fig 13) When the value is below 0 3 mA, remove

and examine the anode and replace if required

- If an impressed current anode is installed, observe the

related product documentation A green light signals

correct function

●

Check for visible leakage of the fittings If necessary

retighten fittings

●

The proper function of the safety valve regularly has to

be tested The blow-off opening must never be closed

or obstructed

●

Required cleaning of the storage tank can be carried

out through the access/cleaning flange Install new

gasket when closing!

Regular maintenance must be certified in the Mainte-

nance Protocol by a qualified person in order to render

the warranty agreement valid

8 Disassembly and Recycling

At the end of the long operational lifetime, the valu-

able materials of the installation should be recycled in

an environmentally sound manner

Figure 13 To check the factory-installed magnesium protection an-

ode unplug cable and measure current with multimeter