EN-RATIOfresh-250-400_TI-MA-0809-11214900

19

5. Initial Startup

5.1 Checking Installation

Check especially the following three points:

●

The correct connection of the pipes based on the con-

nection diagrams in fig. 6 and fig. 7 as well as the de-

scribed assembly steps.

●

The correct placement of the temperature sensor T

buffer

within the aux. heating section of the buffer cylinder. The

controller uses this sensor to detect the available tem-

perature for the functions “circulation” and “standby”.

Temperature sensor T

buffer

also serves to activate the aux.

heating boiler during the thermal disinfection process.

●

If the disinfection function is to be activated, the external

switching output of the RATIOfresh freshwater station

must be connected with the external switching input of

the aux. heating boiler. In this case, the boiler is fired and

the storage charge pump starts when the RATIOfresh

issues a boiler request.

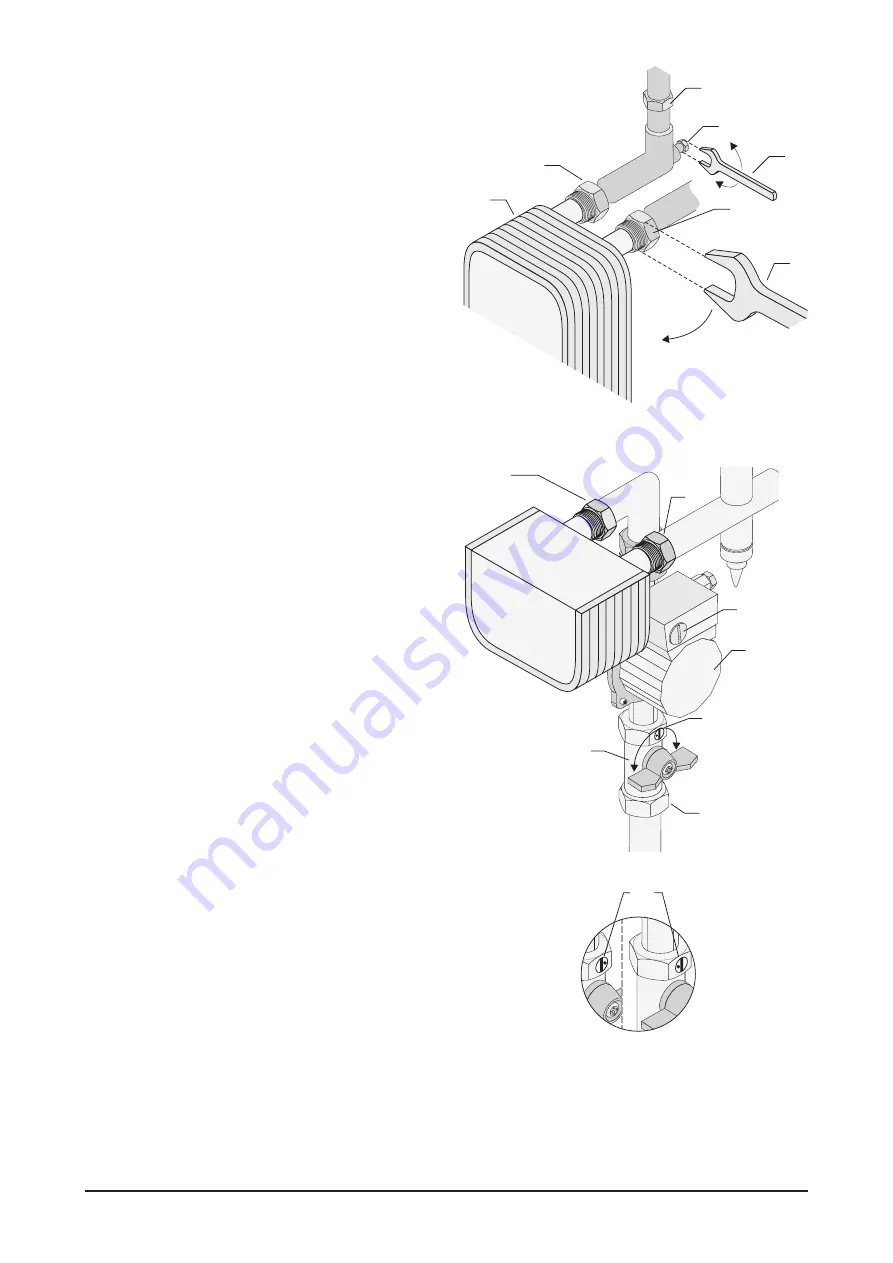

5.2 Filling the Primary Circuit (fig. 11)

Now slowly fill the buffer cylinder and the primary circuit.

This requires inserting the mains plug and switching the

primary circuit pump to the operation mode “Constant” us-

ing the “Manual Mode” menu. Open check valve

(15)

at the

ball cock in the primary return (see fig. 11 enlarged section

for the correct position). Vent the primary circuit during the

filling process.

5.3 Configuring the Controller (fig. 10)

Now configure the controller for the specific on-site condi-

tions. fig. 10 provides an overview over the menu structure

and explains the use of the control keys. Enter the corre-

sponding values into the setting menus in the following

order: “HOT WATER”, “CIRCULATION”, “DISINFECTION”,

“SERVICE”, “LANGUAGE”, and “TIME”. Tables 7 to 13 pro-

vide assistance with selecting the respective values. To

finish, enter the individual configuration into the “Your

Value” column.

5.4 Selecting Pump Level (fig. 11)

The RATIOfresh freshwater station pump has three power

levels (maximum, medium, and minimum). The setting key

(16)

is located on the upper side of the pump switching box.

Select the matching level for the chosen max. tapping vol-

ume based on Table 14. The table values were calculated

based on the assumption that the potable water flows in

with a cold water temperature of 10 °C and is heated by the

RATIOfresh station to a nominal temperature of 45 °C or

60 °C (incl. pressure loss of 0.7 m corrugated tube DN 16

between station and buffer and screw connections):

●

Select the volume flow from column 1, which is the max.

volume you wish to withdraw from the hot water net-

work.

●

The pressure loss listed in column 2 occurs additionally

in your hot water network with the indicated tapping rate

due to the station.

2

5

6

3

4

12

90°

10

11

8

16

7

9

14

15

15

Z

A

Z

A

Ready

for operation

Open

Figure 11 Heat exchanger disassembly

2

1" swivel nut;

3

Heat exchanger;

4

1" swivel nut;

5

Shut-off valve;

6

1" swivel nut;

7

Ball valve;

8

Circulation pump;

9

1¼" swivel nut;

10

1" swivel nut;

11

1" swivel nut;

12

Size 36 wrench;

14

Size 10

wrench;

15

Check valve;

16

Adjustment pump speed.

Содержание RATIOfresh 250

Страница 25: ...EN RATIOfresh 250 400_TI MA 0809 11214900 25 ...

Страница 26: ...26 EN RATIOfresh 250 400_TI MA 0809 11214900 ...