OM D18 us* 1.1 * Sicherheit_25022014.fm

2-19

Safety 2

Bleeding the fuel system and refueling

•

Do not bleed the fuel system or refuel near open flames.

•

Bleed the fuel system and refuel only in well-ventilated areas (for

example due to vapors harmful to health, explosion hazard).

•

Wipe away fuel spills immediately (for example due to fire hazard,

slipping hazard).

•

Firmly close the fuel tank cap, replace a malfunctioning fuel tank cap.

Handling oil, grease and other substances

•

When handling oil, grease and other chemical substances (for example the

battery electrolyte, coolant), observe the safety data sheets.

•

Wear appropriate protective equipment (for example protective gloves,

safety glasses).

•

Be careful when handling hot consumables – burn hazard.

•

In polluted environment (dust, vapors, smoke, asbestos), work only

with appropriate personal protective equipment (for example with a

breathing mask).

•

Do not use machine in radioactive, biological or chemical contami-

nated areas.

Fire hazard

•

Fuel, lubricants and coolants are flammable.

•

Do not put the machine into operation if there is a fire hazard.

•

Do not use flammable detergents.

•

Keep the area around the exhaust system free of flammable materials.

•

Due to hot machine parts, maintain a safe distance from easily

flammable material (for example from hay, dry leaves).

- Stop and park the machine only in fire-protected areas.

•

If the machine is equipped with a fire extinguisher, have it installed in

its specific location.

•

Keep the machine clean to reduce the fire hazard.

Working near electric supply lines

•

Before performing any work, the operator must check whether there

are any electric supply lines in the job site.

•

If there are electric supply lines, only a machine with cabin may be

used (Faraday cage).

•

Keep a safe distance from existing electric supply lines.

•

If this is not possible, the operator must take other safety measures (for

example switching off the current) in agreement with the operating

company or owner of the supply lines.

•

If supply lines are exposed, they must be fastened, supported and

secured accordingly.

•

If live supply lines are touched nevertheless:

- Do not leave/touch the cabin (Faraday cage)

- If possible, drive the machine out of the danger zone

- Warn others against approaching and touching the machine

- Have the live wire de-energized

- Do not leave the machine until the supply lines that have been

touched or damaged have been safely de-energized

Содержание DW100

Страница 18: ...1 8 BA D18 us 1 1 D18v100 fm 1 Foreword Notes...

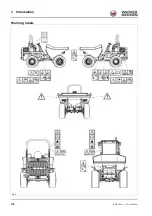

Страница 46: ...3 8 BA D18 us 1 1 D18e300 fm 3 Introduction Warning labels Fig 9...

Страница 50: ...3 12 BA D18 us 1 1 D18e300 fm 3 Introduction Information labels Fig 20...

Страница 54: ...3 16 BA D18 us 1 1 D18e300 fm 3 Introduction ANSI label option Fig 36...

Страница 60: ...3 22 BA D18 us 1 1 D18e300 fm 3 Introduction Notes...

Страница 144: ...6 10 BA D18 us 1 1 D18t600 fm 6 Transportation Notes...

Страница 200: ...8 8 BA D18 us 1 1 D18b800 fm 8 Malfunctions Notes...

Страница 216: ...9 16 BA D18 us 1 1 D18t900 fm 9 Technical data 9 15 Dimensions Front skip overview...

Страница 218: ...9 18 BA D18 us 1 1 D18t900 fm 9 Technical data Swivel skip with rollbar overview...

Страница 220: ...9 20 BA D18 us 1 1 D18t900 fm 9 Technical data Swivel skip with cabin overview...

Страница 222: ...9 22 BA D18 us 1 1 D18t900 fm 9 Technical data...

Страница 226: ......

Страница 227: ......