WACHS TRAV-L-VAC 300

14

BLOWER MAINTENANCE SCHEDULE

WEEKLY

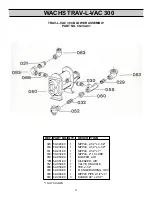

CHECK OIL LEVEL:

Stop blower. Wait 5 minutes. Remove oil breather and

oil level plug. Add oil until oil runs out level holes. Re-

place breather and level plugs.

GREASE BEARINGS:

Grease drive end bearings with NLGI grade 2 EP grease

in a pressure gun. Force into housing through grease

fittings until clean grease emerges from relief fittings.

Wipe clean all grease from around relief fittings to pre-

vent spraying onto drive belts.

EVERY 1,000 HOURS

CHANGE OIL.

NOTES

Change oil after initial 100 hours.

Recommended oil: Mobil DTE BB, Amoco 220, Texaco

R&O 220, or equivalent .

FILTER MAINTENANCE SCHEDULE

DAILY

Clean primary filter.

WEEKLY

Clean pre-filter

NOTES

Frequency of cleaning will increase under severe oper-

ating conditions.

All filters are washable with mild detergent and water.

Damaged filters must be replaced to prevent debris from

reaching blower.

MAINTENANCE

ENGINE MAINTENANCE SCHEDULE

DAILY

Check oil level.

Replenish fuel intake supply ( Unleaded fuel ).

Clean air intake screen.

Check tightness of air cleaner cover.

EVERY 25 HOURS

Service pre-cleaner.

EVERY 100 HOURS

Service paper element.

Remove shrouds, clean cooling fins, and external sur-

faces.

Check battery electrolyte level.

Change oil.

EVERY 200 HOURS

Check spark plug condition and gap, change oil filter.

NOTES

Change oil after first 5 hours.

BLOWER MAINTENANCE DIAGRAM

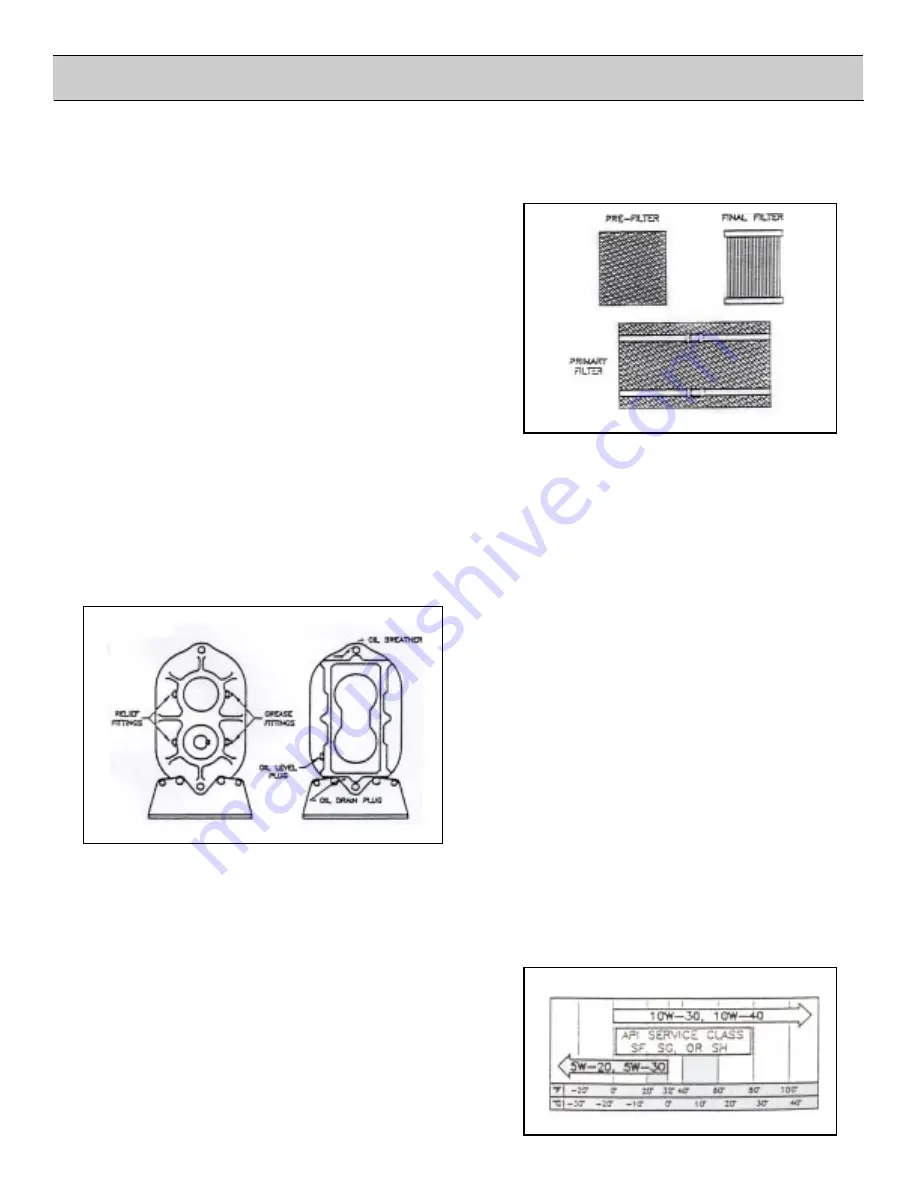

OIL GRADE DIAGRAM

FILTER MAINTENANCE DIAGRAM

Содержание TRAV-L-VAC 300

Страница 2: ......

Страница 6: ......

Страница 7: ...WACHS TRAV L VAC 300 7 SECTIONIV SET UP AND OPERATING PROCEDURES...

Страница 9: ...WACHS TRAV L VAC 300 9 SECTION IV SET UP AND OPERATION INSTALLATION DIAGRAM...

Страница 13: ...WACHS TRAV L VAC 300 13 SECTIONV MAINTENANCE...

Страница 16: ...WACHS TRAV L VAC 300 16 SECTIONV MISCELLANEOUS CHARTS AND GRAPHS...

Страница 17: ...WACHS TRAV L VAC 300 17 TRAV L VAC 300ACOUSTIC EVALUATION SOUND DECIBLE LEVEL DIAGRAM 10 FT...

Страница 18: ...WACHS TRAV L VAC 300 18 TRAV L VAC 300PERFORMANCE CHARTS...

Страница 19: ...WACHS TRAV L VAC 300 19 BILL OF MATERIAL...

Страница 21: ...WACHS TRAV L VAC 300 21...