36

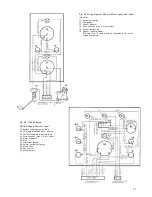

32. Fuel injection pump

NOTE! Any repair work required to be done on the fuel

injection pump should be carried out by specially trained

mechanics who have the necessary tools and testing

devices at their disposal. All warranty on the engine be-

comes null and void if the seals are broken by unauthori-

zed persons.

Since operating conditions vary considerably, it is difficult

to indicate any definite interval, but the pump settings, max.

and idle speeds, exhaust smoke, etc. should generally be

checked after every 2400 hours of operation.

Always check and clean the injectors and make sure that

the air lines to the turbo do not leak before checking the

engine exhaust smoke. The air cleaner should also be cle-

aned and the air lines must be free from constrictions.

In order to ensure even loading of the cylinders, the fuel in-

jection pump should be checked on a test bench. This is

extremely important with regard to engine life. This check is

preferably carried out in connection with the laying-up of

the boat at the end of the season.

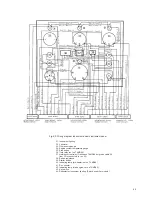

33. Turbo-compressor

Check the turbo-compressor thoroughly after every 2400

hours of operation with regard to leakages of the oil lines

and air hoses. Check also the bearing clearance and char-

ging pressure as well as the general condition of the unit.

This check should be carried out by authorized personnel.

If necessary, replace the turbo-compressor with a new or

reconditioned unit.

Always fit new oil filters and change the engine oil when

replacing the turbo-compressor. Fill the turbo-compressor

bearing housing with 0.1 litre (0.1 quart) of oil before con-

necting the oil delivery pipe.

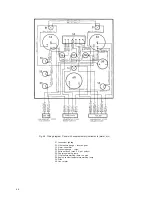

34. General checking

It is difficult to indicate a definite time for reconditioning the

engine since operating conditions vary considerably. By

measuring the compression pressure and observing the

consumption of lubricating oil it is, however, possible to

estimate roughly when the engine should be dismantled

and checked for wear.

In connection with a major overhaul of the engine, the re-

verse gear and reduction gear, if fitted, should also be

removed and checked for wear.

Cylinder heads and gaskets

Both cylinder heads have separate steel gaskets with spe-

cial rubber seals for sealing against water and oil.

A used gasket must never be refitted. Always fit a new gas-

ket. The cylinder head bolts should be tightened with a tor-

que wrench and in the correct sequence by personnel from

an authorized service workshop.

The valve clearance should always be adjusted after the

cylinder heads have been tightened.

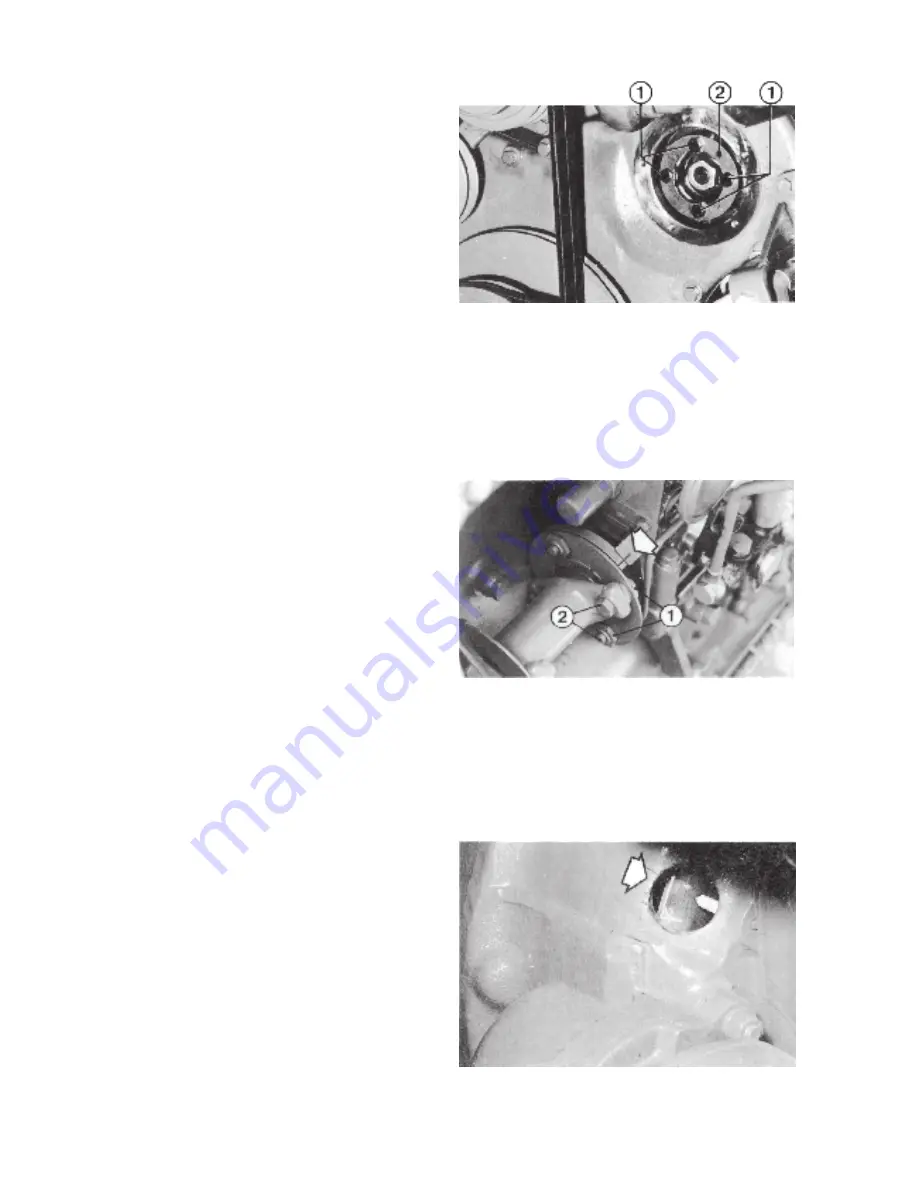

Pump drive TAMD 60

1. Screws in drive flange

2. Lock washer

Pump coupling (protective cover removed) 70-engines

1. Nuts

2. Coupling screws

Angle graduation marking on flywheel

Содержание AQD70C

Страница 1: ...INSTRUCTIONBOOK TAMD60A B TAMD70C D AQD70C D ...

Страница 52: ...7731201 5 English 7 1979 ...