32

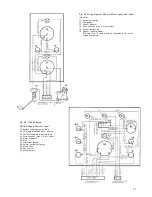

28. Starter motor, alternator and

fuses

NOTE! Disconnect both battery cables before carrying

out any work on the electrical system.

Starter motor, checking brushes and commutator

This check should be carried out after every 1200 hours of

operation.

Disconnect the starter motor cables and remove the starter

motor. Take off the starter motor protective cover. Lift the

brush springs and pull out the brushes. These should run

easily in their holders. Clean dirty or sticking brushes with a

cloth moistened with petrol (gasoline). Replace damaged

or worn brushes. If the commutator is scored, oval or burnt,

the starter motor should be reconditioned by authorized

service personnel. Check the tension of the brush springs

by using a spring balance. The spring force should be ap-

prox. 12-14N (1.2-1.4 kp = 2.6-3.1 lbf). Replace faulty

springs.

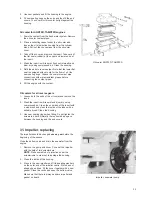

Alternator, checking brushes and slip rings.

The check should be carried out after every 1200 hours of

operation.

Small alternator

Clean the alternator externally. Unscrew the nuts on both

terminals on the alternator end cover (one of the terminals

is marked DF).

Remove the cover and unscrew both the brush holder

screws. Carefully lift out the brush holder taking care not to

damage the brushes.

Check that the brushes run easily in their holders and that

at least 5 mm of the brushes project and that the brush ca-

bles are not damaged and are well soldered. If necessary,

replace the complete brush holder including the brushes. If

the slip rings are scored, they should be rectified by autho-

rized service personnel.

Large alternator (1600W. Optional equipment)

Clean the alternator externally. Check that the ventilation

holes in the front end are open.

Remove the cover, the casing and the brush cap at the rear

end of the alternator. Remove the screws retaining the

brush cap and then carefully bend up the cap. Note the

rubber gasket.

Check that the length of the brushes is at least 8 mm and

that they run easily in their holders. Check that the brush

cables are undamaged and well secured.

Check that the brush spring force is 2.3-2.8N (0.23-0.28 kp

= 0.5-0.6 lbf).

Also check the slip rings. Scored or corroded slip rings

must be rectified by authorized service personnel.

If it is necessary to replace the brushes, loosen the connec-

tion screws, lift up the springs and pull out the brushes. As-

sembly is carried out in reverse order.

Содержание AQD70C

Страница 1: ...INSTRUCTIONBOOK TAMD60A B TAMD70C D AQD70C D ...

Страница 52: ...7731201 5 English 7 1979 ...