16

GT ULTRA ZERO AIR GENERATOR

USER MANUAL

www.vicidbs.com

Version 1.03.0000

6.8. LEAK CHECK

Before powering the generator, perform a leak check on the external plumbing.

• Open supply air valve to pressurize the system.

•

Apply certified liquid detectors to all external fittings and check for air bubbles.

•

Tighten any leaky connections. Additional Teflon tape may be required in some cases.

7.2. WARMING UP

After power-up, the system goes through a warm-up cycle.

The yellow “Warm-up/Check Pressure” LED flashes at 1 Hz, indicating the system is in warm-up mode. If

the catalyst temperature is above the minimum level of 485°C and no faults are detected, the system will

go immediately to operation mode. This quick-start feature is for customer convenience when power is

interrupted only for short periods, and a full warm-up cycle is not required. Warm-up cycle takes 45 min.

GT Ultra Zero Air generator is designed to run continuously. Continuous operation preserves the

performance of the catalyst. Shutdown should only be performed for maintenance.

Verify that:

• “POWER” green LED is on

•

“WARM UP” yellow LED is flashing

7. OPERATION

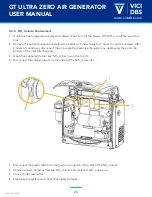

7.1. CONNECT POWER AND START UNIT

To start unit:

• Insert the female end of the supplied power cord to the power supply connection on the left side of the

unit, and plug the male end into a properly grounded socket.

• Power up the unit using the power switch on the unit.

•

For the first 3 seconds, all panel LEDs will be illuminated. This verifies proper operation of the control

board firmware and the LEDs.