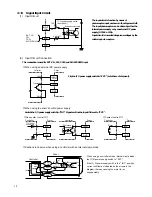

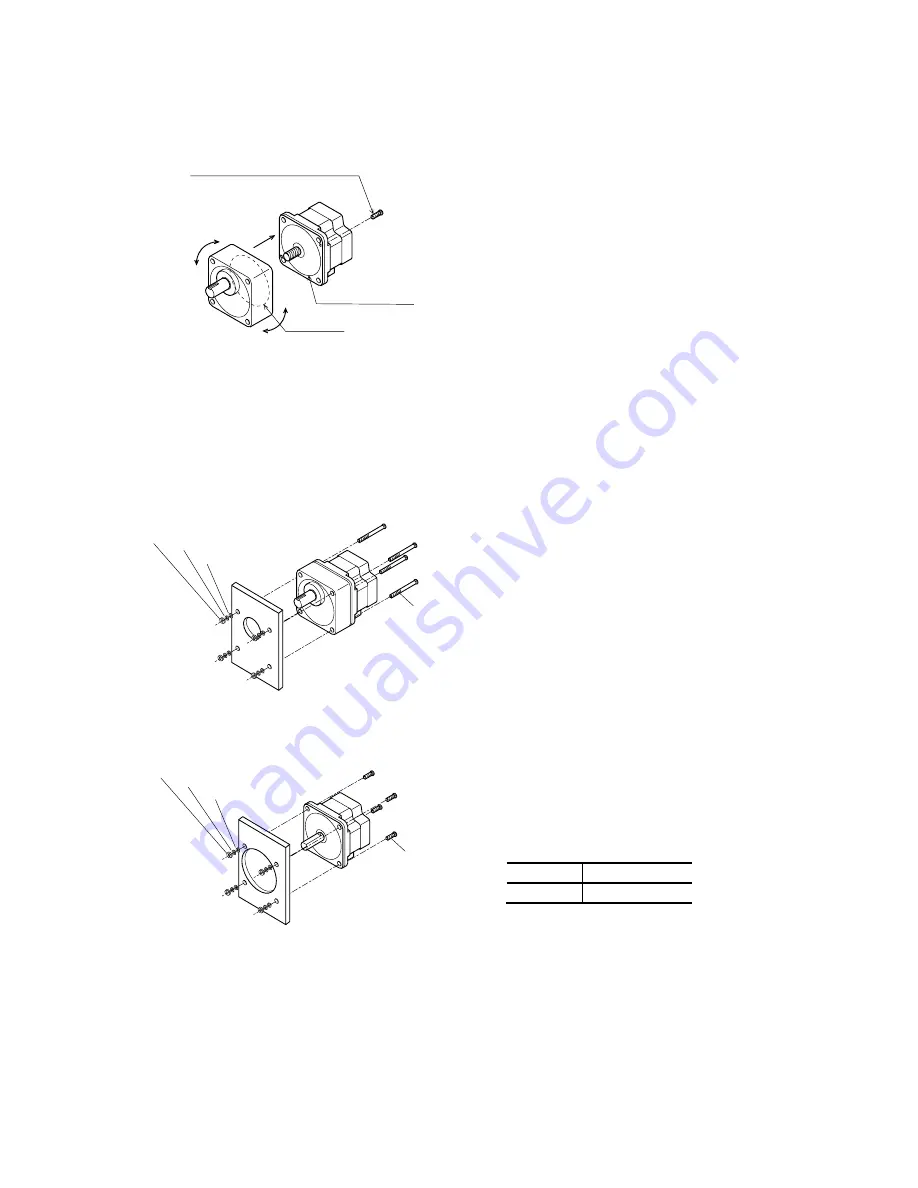

(3) Assembling the Motor and Gearhead (Pinion shaft motor)

Continue to the next page if you have a round shaft type or combination type motor.

When attaching a pinion shaft type motor to a gearhead, use the

pilot of the motor and gearhead as guides, and gently rotate the

gearhead back and forth until it fits in place, as shown in the

figure at the left. When the gearhead is in place, fasten it to the

motor using the screws provided .

Note Clean any dirt off the pilot section of the motor and gearhead.

Insufficient cleaning may cause incomplete attachment and leaking of grease within the gearhead.

Don't pinch the O-ring when assembling the motor and gearhead.

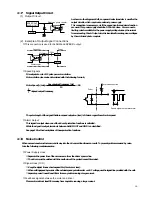

(4) Installing on Other Devices

■

Combination Type And Pinion Shaft Motor

To install motor and gearhead to machinery, make installation

holes in the mounting place.

Use screws provided with gearhead and secure the motor so

that there are no gaps between the motor flange surface,

gearhead surface and the mounting surface.

For dimensions of installation holes and the detail of

mounting, see the operating manual of gearhead.

■

Round shaft Motor

To install motor to machinery, make installation holes in the

mounting place.

Use 4screws and secure the motor so that there are no gaps

between the motor flange surface and the mounting surface.

Four screws are necessary for mounting (not provided).

6

Motor

Gearhead

Mounting

plate

Screws provided

with gearhead

Plain washer

Spring washer

Nuts

Motor

Mounting

plate

Screws

Plain washer

Spring washer

Nuts

Motor

Motor and gearhead assembly screws

(Use 2screws)

Gearhead

Pilot Section

(with O-ring attached)

Pilot Section

Clamping Torque

10N

・

m (100

㎏f㎝

)

Motor and Gearhead assembly screws Size : M3

Screw size

M8