3. Installation

Installation conditions

Install the motor and driver in a location that meets the following conditions. Using the unit in a location that does not satisfy

these conditions could damage it.

・

Indoors (this product is designed and manufactured to be installed within another device)

・

Ambient temperature : 0

℃〜

+50

℃

(avoid freezing)

・

Ambient humidity : 85% max. (avoid condensation)

・

Not exposed to explosive, flammable, or corrosive gas

・

Not exposed to direct sunlight

・

Not exposed to dust

・

Not exposed to water or oil

・

A place where heat can escape easily

・

Not exposed to continuous vibration or excessive impact

・

1000 meters or less above sea level.

・

Overvoltage category

Ⅱ

, Pollution degree 2, Class

Ⅰ

(For EN Standard)

When the machinary to which the motor and driver are mounted requires overvoltage category

Ⅲ

and pollution degree 3

specifications, install the motor in a cabinet that comply with IP54 and connect to power supply via an isolation transformer.

3.1

Motor Installation

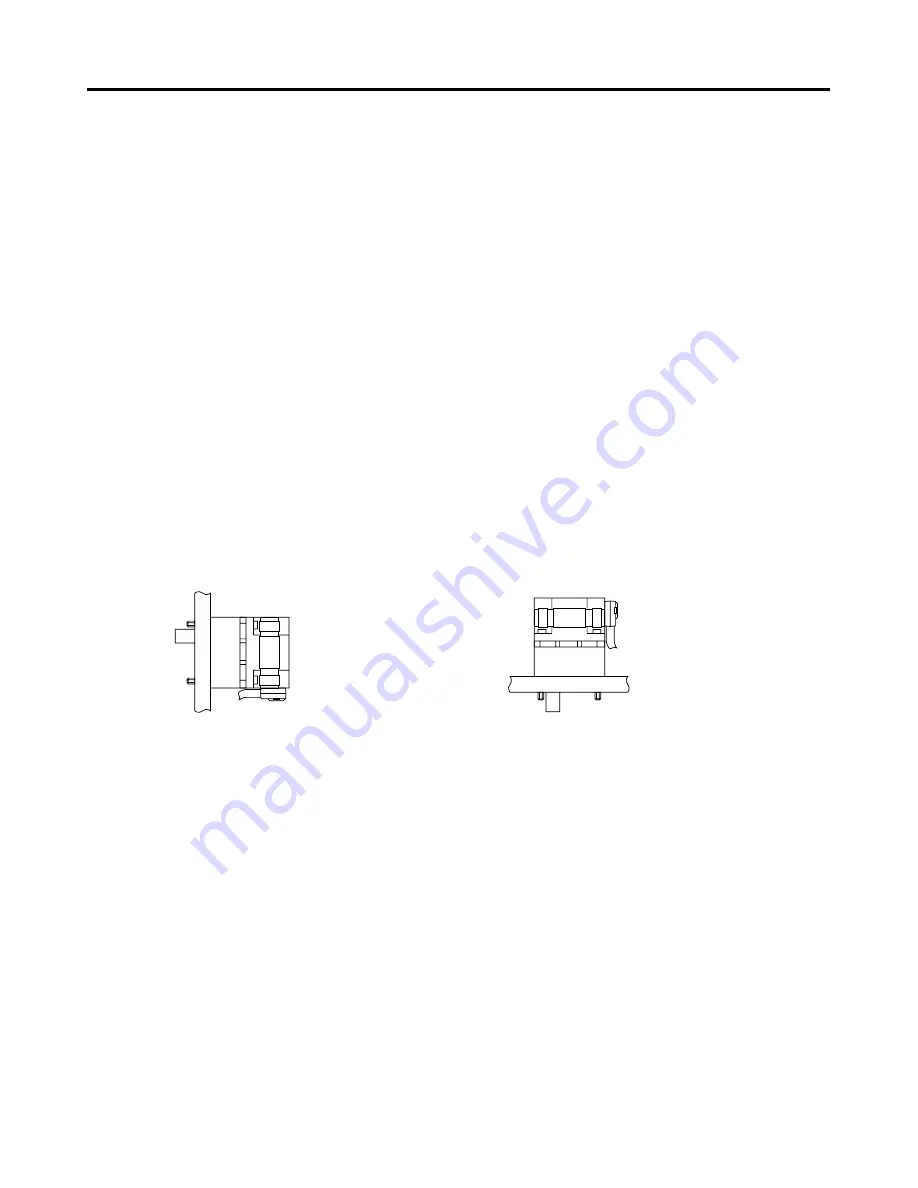

(1) Direction of Motor Installation

Motors may be installed either horizontally or vertically.

■

Horizontal mounting

■

Vertical mounting

(2) Connecting to Other Equipment (Loads)

When connecting motors to another piece of equipment (load), the motor shaft must be centered. When not properly centered,

vibration will result and ball bearing life will be shortened dramatically, causing motor shaft damage.

The alignment of the coupling used, must be within its specification.

Note When attaching couplings, timing pulleys, gears or the like to a motor shaft, be sure not to subject the motor

shaft to impacts. The ball bearings within the motor may become damaged.

5

Gearhead Motor

Mounting plate

Gearhead

Mounting plate

Motor