1.

Mount the fork arm on the fork carrier and close the locking device.

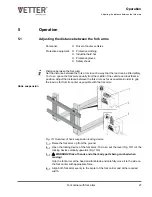

Fig. 12: Upward bending of the hook (view from above)

2.

Use a measuring tool (e.g., feeler gage) to measure the gap between the block of

the locking device and the head of the fork arm (Fig. 12).

3.

If a measured value of 0.079 inches (2 mm) is exceeded, immediately ban any

further use of the fork arm. Commissioning must only be carried out after a suc-

cessful repair or replacement.

Personnel:

n

Service specialist

Protective equipment:

n

Protective clothing

n

Industrial hard hat

n

Protective gloves

n

Safety shoes

Special tool:

n

Measuring tool (caliper gage, feeler gage)

The sockets of the shaft fork arms are used for both power transmission and to guide

the fork arms onto the shaft. Defective or severely worn sockets must be replaced

immediately.

Suspension of shaft

fork arms

Maintenance

Checking the fork arms > Checking the suspension

Fork carrier with fork arms

35

Содержание ManuTel

Страница 2: ...Fork carrier with fork arms 2 ...

Страница 52: ......