- 11 -

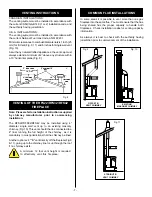

CLEANING PROCEDURE

1.

Turn off pilot light at gas valve.

2.

Remove front glass.

3.

Remove logs.

CAUTION: LOGS MAY BE HOT

4.

Vacuum burner compartment especially around orifice/

primary air openings.

5.

Reinstall logs.

6.

Check pilot and main burner operation.

7.

Reinstall front glass.

8.

Recheck pilot and main burner operation.

9.

Check visually the flame pattern and compare with Fig.

21 or 22.

Fig. 18a

FLAME ADJUSTMENT (RN/RP MODELS)

For units equipped with Hi/Lo valves, flame adjustment

is accomplished by rotating the Hi/Lo adjustment knob

located near the centre of the gas control. (Fig. 18a & b)

L O

HI

Turn

counterclockwise

to increase

flame height.

Turn clockwise

to lower

flame height.

CERAMIC REFRACTORY

RFS42 ONLY

1. Remove bay window assembly and glass frame (see "Glass

frame Removal" section).

2. Remove logs from the unit.

LOGS MAY BE HOT

3. Remove refractory from packaging.

Refractory are fragile and must be handled with

care. Where at all possible, two hands should be

used when handling.

4. Take centre refractory piece and place it at the very back of

the firebox.

5. Take left or right side refractory and slide it along the side

of the firebox and on top of the bottom support channel. Be

sure to slide it back to hold the centre piece in place and the

leading edge faces forward.

6. Fasten top tab support against the refractory to hold it in

place.

7. Repeat steps 5 and 6 for remaining side refactory.

8. Insert refractory pieces into the Bay Window as per Fig. 23.

Leading

Edge

Leading

Edge

Left

Side

Centre

Right

Side

Fig. 22

Fig. 23

LO

HI

Turn

counterclockwise

to decrease

flame height.

Turn clockwise

to increase

flame height.

TEMPERATURE ADJUSTMENT

(TN/TP MODELS)

HI

OFF

PILOT

LO

Fig. 19

The Hi/Lo reference on the control knob (Fig. 19) is to

indicate a higher or lower temperature setting. This setting

controls the heat by reducing then

shutting off the flame as the desired

temperature is reached. Position

the control knob where it effectively

maintains a comfortable room

temperature.

It is important to periodically perform a visual

check of the pilot and the burner flames.

Compare them to the pictorials illustrated

below (Fig. 20, 21). If any of the flames

appear abnormal call a service person.

FLAME CHARACTERISTICS

Fig. 21

RFS22

RFS32

RFS42

3/8" - 1/2"

Fig. 20

Fig. 18b

SIT VALVE

PSE VALVE