SERVICE

Service - 53

ROPS And Seat Belt Inspection

WARNING

Failure to inspect and maintain the Roll-Over Pro-

tection System (ROPS) and seat belt can lead to

serious injury or death.

If any part of the ROPS experiences structural

damage, the entire ROPS must be replaced.

Inspect the roll bar and seat belt prior to operation,

as part of the daily inspection.

1. Inspect the roll bar for damage, missing compo-

nents, and loose or missing hardware. Replace

any damaged or missing components and tighten

loose hardware prior to operating the power unit.

2. Inspect the seat belt webbing for cuts, abra-

sions, fraying, or excessive wear.

3. Inspect the seat belt webbing for damage from

exposure to the sun’s ultraviolet rays. If the original

color of the webbing is extremely faded, the physi-

cal strength of the webbing may be deteriorated.

4. Inspect the seat belt webbing for dust and dirt.

If the webbing is packed with dirt, the physical

strength of the webbing may be deteriorated.

5.

Inspect the seat belt webbing for stiffness. If

the webbing is no longer flexible, the physical

strength of the webbing may be deteriorated.

6. Inspect the seat belt buckle and latch for dam-

age, cracks, or excessive wear.

7. Inspect the seat belt for proper operation. The

seat belt should latch securely and release

smoothly. Seat belt adjustment should be

accomplished without excessive resistance.

If any problems are detected during this inspection,

the component must be replaced prior to operating

the power unit.

Parking Brake Inspection & Adjustment

The parking brake tension must be set between a

minimum of 15 pounds (7 kg) and a maximum of

22 pounds (10 kg) of force required to engage the

selector lever into the park brake position. If the

force required to engage the selector lever into the

park position is not within this range, or if engaging

the park brake will not prevent the power unit from

moving, the brake will need to be adjusted.

1. Park the power unit on a level surface.

2.

Shut off the engine and remove the key from the

ignition switch.

3.

WARNING

The parking brake must be disengaged as part of

the adjustment procedure. Park the power unit on

a level surface and place wheel chocks in front

and back of wheels to prevent the power unit from

rolling forward or backward.

Place wheel chocks in front and back of wheels

to prevent power unit from rolling.

4.

WARNING

If power unit is not adequately supported, the unit

could accidentally fall and trap or crush a person

or appendage, causing severe injury or death.

Lift the left front corner of the power unit so the

left front tire is off the ground and secure the

power unit with a jack stand or supporting block.

5. Remove the left front tire to provide easier

access to the brake adjustment castle nut.

6.

Place the selector lever in the Neutral Assist Off

position.

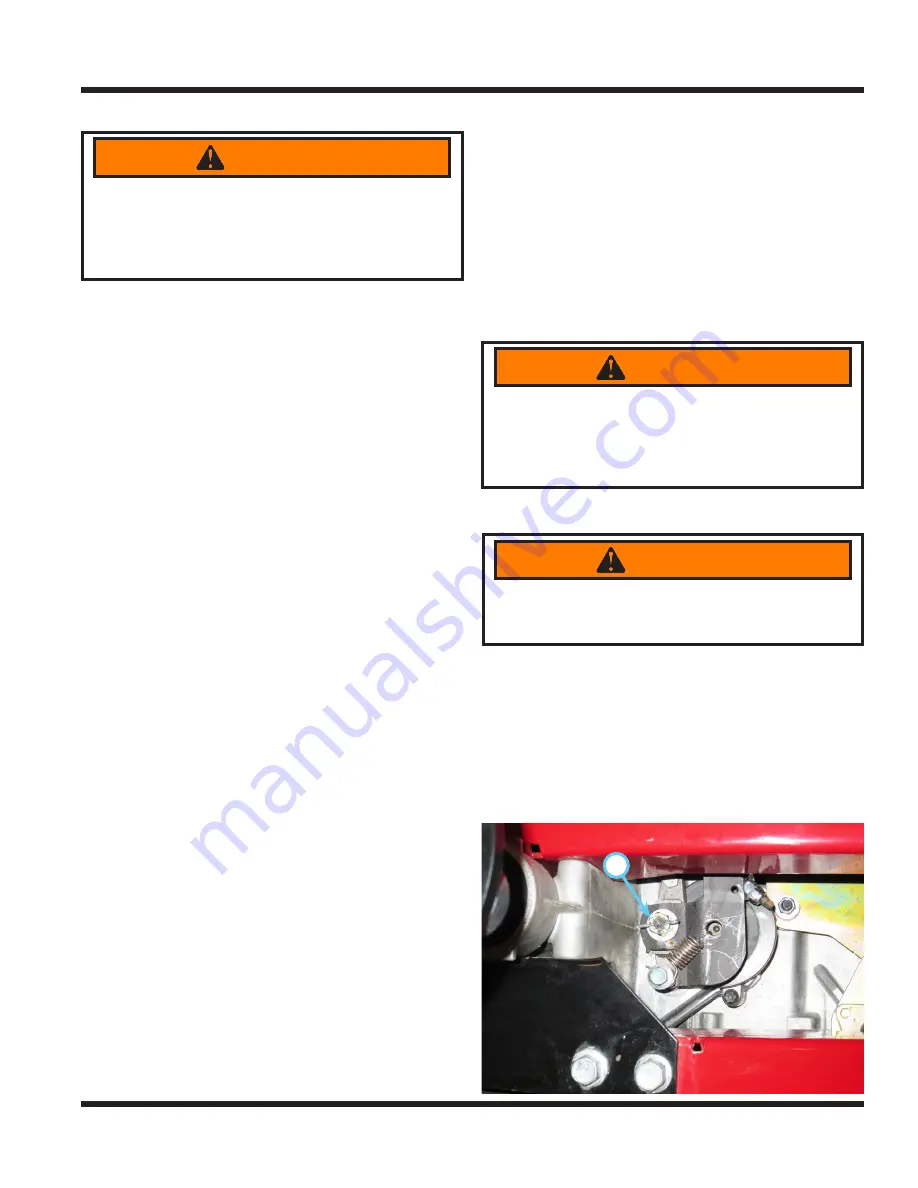

7. Remove the cotter pin from the brake adjust-

ment castle nut (A).

A