3.0 Installation

6

CE-1-11/00

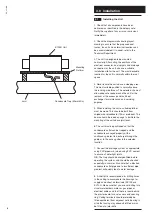

3.1

Installing the Unit

1. Check that all components have been

delivered, as identified in the delivery note.

Notify the supplier of any errors or omissions

immediately.

2. Check the diagrammatic ducting layout

drawing to ensure that the proposed duct

routes, fan unit and air terminal locations can

be accommodated. If in doubt, refer to the

Technical Department.

3. The unit is designed to be mounted

horizontally. After noting the positions of the

electrical connector, duct spigots and drainage

connection for the unit, choose a suitable

installation site for the unit. The most desirable

location for the unit is normally within the roof

space.

4. Never locate the unit above a sleeping area.

The most suitable position is normally above

the landing or bathroom. The selected site must

allow adequate space around the unit for the

removal of the access panel and heat

exchanger for maintenance and servicing

puposes.

5. When installing the unit, a suitable platform

must be made. This should be built from

chipboard or blockboard (19mm preferred). This

board should be raised enough to facilitate the

mounting of the unit above joist level.

6. The unit must be positioned so that the

condensate outlet can be trapped and the

condensate conveyed properly with a

continuous gradient to discharge through the

gable or to the eaves gutter in the selected

location.

7. Connect the drainage system as appropriate

using PVC pipework, joined using PVC cement

to ensure of watertight joints.

N.B. The trap should be charged/filled before

operating the system, and should be checked

especially in summer. Also note that a blocked

condensate outlet pipe due to insufficient pipe

gradient will quickly lead to water damage.

8. A shell bit is recommended for drilling holes

in the ceiling to accomodate the housings for

supply and extract air terminals (SV100 and

EV100). Make sure that you are not drilling into

structural members, water or gas pipes or

electrical cables and that there is room behind

the plaster board for duct access and securing

ring. Ceiling terminals should preferably be

fitted equidistant from adjacent walls bearing in

mind that coving may already be fitted or may

be fitted at a later date.

E100R Unit

Joist

Condensate Trap (50mm Min)

Mounting

Platform

Содержание HR100R

Страница 2: ...CE 1 11 00 2...

Страница 14: ...8 0 Notes 14 CE 1 11 00...

Страница 15: ...CE 1 11 00 15...

Страница 16: ...CE 1 11 00 Vent Axia Ltd Fleming Way Crawley West sussex RH10 9YX www vent axia com Comp No 370666 Iss C 0310...