114

106309-03 - 4/19

Follow manufacturer application procedure

for proper heating system/boiler cleaning and

preventive treatment.

Above referenced products are available from

Alent plc, Consumer Products Division, 4100

6th Avenue, Altoona, PA 16602, Tel: (972)

547-6002 and/or selected HVAC distributors.

Contact Velocity Boiler Works, LLC for

specific details.

iii.

Sentinel

®

X400 System Restorer (For Older

Closed Loop Hydronic Heating Systems)

iv.

Sentinel

®

X300 System Cleaner (For New

Heating Systems)

v.

Sentinel

®

X100 Inhibitor (For Protecting

Closed Loop Hydronic Heating Systems

Against Lime scale And Corrosion)

Follow manufacturer application procedure

for proper heating system/boiler cleaning and

preventive treatment.

Above referenced products are available from

Douglas Products and Packaging, 1550 E. Old

210 Highway, Liberty, MO 64068, Tel:(877)

567-2560 (Toll Free) and/or selected HVAC

distributors.

vi.

Equivalent system water treatment products

may be used in lieu of products referenced

above.

2. System Freeze Protection:

a. The following heating system freeze protection

products are recommended for Phantom X boilers:

i.

Fernox™ Protector Alphi 11 (combined

antifreeze and inhibitor).

Follow manufacturer application procedure

to insure proper antifreeze concentration and

inhibitor level.

Above referenced product is available from

Alent plc, Consumer Products Division, 4100

6th Avenue, Altoona, PA 16602, Tel: (972)

547-6002 and/or selected HVAC distributors.

Contact Velocity Boiler Works, LLC for

specific details.

ii.

Sentinel

®

X500 Inhibited Antifreeze

(combined antifreeze and inhibitor)

Follow manufacturer application procedure

to insure proper antifreeze concentration and

inhibitor level.

Above referenced products are available from

Douglas Products and Packaging, 1550 E. Old

210 Highway, Liberty, MO 64068, Tel:(877)

567-2560 (Toll Free) and/or selected HVAC

distributors.

b. Equivalent system freeze protection products

may be used in lieu of product referenced above.

In general, freeze protection for new or existing

systems must use specially formulated glycol,

which contains inhibitors, preventing the glycol

from attacking the metallic system components.

Insure that system fluid contains proper glycol

concentration and inhibitor level. The system should

be tested at least once a year and as recommended by

the manufacturer of the glycol solution. Allowance

should be made for expansion of the glycol solution.

WARNING

Poison Hazard. Use only inhibited propylene

glycol solutions specifically formulated for

hydronic systems. Do not use ethylene glycol,

which is toxic and can attack gaskets and seals

used in hydronic systems. Use of ethylene

glycol could result in property damage, personal

injury or death.

E. Condensate Overflow Switch and Condensate

Trap Removal and Replacement:

For removal or replacement of the condensate overflow

switch and/or condensate trap follow the steps below. For

parts identification, refer to Section XIII “Repair Parts”.

1. Condensate Overflow Switch Removal and

Replacement:

a. Disconnect power supply to boiler.

b. Remove 2 wire nuts and disconnect overflow switch

wire pigtails from boiler wiring.

c. Using pliers, release spring clip securing the

overflow switch to condensate trap body and remove

the switch. Note that the switch has factory applied

silicon adhesive seal, which may have to be carefully

cut all around to facilitate the switch removal.

d. Insure the trap overflow switch port is not obstructed

with silicon seal debris, clean as needed.

e. Apply silicon sealant to the replacement switch

threads and install the switch into the trap body

making sure it is properly oriented - the arrow

molded into the switch hex end side must face

down for proper switch operation. See Figure 60

“Condensate Overflow Switch Orientation” for

details.

f. Reconnect the switch wire pigtails to the boiler

wiring and secure with wire nuts.

XI. Service and Maintenance

(continued)

Содержание Phantom-X Series

Страница 15: ...15 106309 03 4 19 III Pre Installation and Boiler Mounting H Boiler Stacking continued Figure 5 Boiler Stacking...

Страница 49: ...49 106309 03 4 19 VI Water Piping and Trim continued Figure 28 Near Boiler Piping Heating Only...

Страница 63: ...63 106309 03 4 19 VIII Electrical continued Figure 40 Ladder Diagram...

Страница 64: ...64 106309 03 4 19 VIII Electrical continued Figure 41 Wiring Connections Diagram 2...

Страница 73: ...73 106309 03 4 19 IX System Start up continued Figure 47 Operating Instructions...

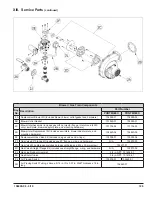

Страница 124: ...124 106309 03 4 19 XIII Service Parts continued...

Страница 126: ...126 106309 03 4 19 XIII Service Parts continued PHNTM600C PHNTM700C and PHNTM800C PHNTM800C shown...

Страница 130: ...130 106309 03 4 19 XIII Service Parts continued...

Страница 133: ...133 106309 03 4 19 XIII Service Parts continued 10A 10B 10C 10D 10G...

Страница 139: ...139 106309 03 4 19...