21

P

T

8.

•

•

•

.03.2011

Preparation

The proced

•

Switch

•

Set ‘co

•

Sort to

The followin

•

SMT Tw

•

Flux di

•

Low so

Temperatur

In normal o

system is d

150W short

maximum o

In normal u

provided by

Soldering

•

PREPARA

centre o

thicknes

apply so

o

[A]

P

o

[B]

R

the c

durin

phase

o

[C]

S

o

[D]

C

Desolderin

•

PREPARA

centre o

o

[A]

P

o

[B]

R

the c

durin

time

o

[C]

S

o

[D]

C

Aftercare

•

Clean flu

•

Check so

•

Test

.

Q&A

What Top H

Between

What’s the

Approxim

Move th

compone

What pre-h

Between

n

ure for prep

h on and war

ontrol setting

ools and flux

ng tools are

weezers, fin

ispenser bot

olids and gel

re profile

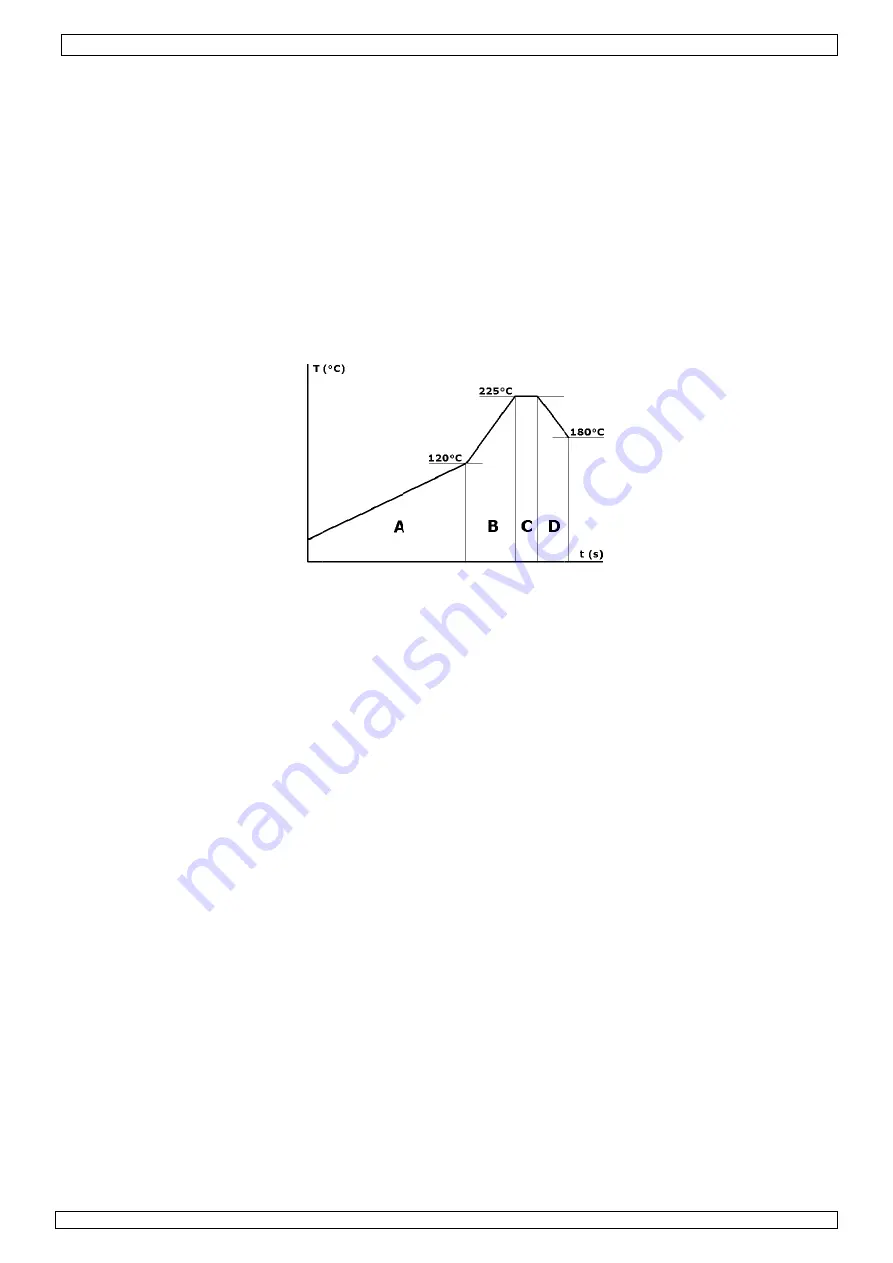

operation the

esigned for

t wave IR lam

of 650W med

use, approxim

y the back h

ATION: plac

of the PCB pr

ss). Place an

older paste to

PREHEAT the

REFLOW: use

omponent u

ng the reflow

e time (norm

SOAK for a s

COOL: allow

ng

ATION: plac

of the PCB pr

PREHEAT the

REFLOW: use

omponent u

ng the reflow

(normally 3

SOAK for a s

COOL – allow

ux residue of

older joints

Heat setting

n 220 and 38

working dist

mately 5~10

e hand tool

ent.

eater setting

n 200 and 29

aring to rew

rm up.

gs’ required

xes required.

required for

e tipped

ttle

/paste flux

e component

rework sing

mp focused

dium wave I

mately 25%

eater (pre-h

e the PCB in

re-heater. Fo

d align comp

o the PCB be

e fluxed com

e the IR han

p to reflow t

w phase so th

mally 30-45

short period

the compon

e PCB in the

re-heater. Ap

e fluxed com

e the IR han

p to reflow t

w phase so th

0-45 second

short period

w the compo

ff PCB if nec

should you u

80°C. Norma

tance of the

0 mm when

in a scannin

g should I us

90°C. Norma

work SMT/BG

for PCB/com

.

r use in solde

t is first put

le/double sid

through a re

IR.

of the energ

heater). Figu

n the PCB ho

or BGAs, app

ponent.

Not

efore placing

mponent/PCB

nd tool (oper

temperature

herefore we

seconds for

soak (about

nent to cool

e PCB holder

pply a very s

mponent/PCB

nd tool (oper

temperature

herefore we

ds for a smal

soak (about

onent to coo

cessary

use?

al setting is

IR Hand too

reworking a

g motion to

se?

al setting is

VTSDIR

6

GA componen

mponent

ering/desold

through a p

de and mixe

eflective cha

gy is proved

re below sho

older, positio

ply a very sm

te

– dependi

g component

B to approxim

rated by pre

e (200-225°C

use the time

a small PCB

t 10 seconds

to below 18

r, positioning

small amoun

B to approxim

rated by pre

e (200-225°C

use the time

ll PCB).

t 10 seconds

l to below 18

240°C.

ol and how d

nd move up

heat leads,

240°C.

nts is as follo

dering operat

preheat stage

d technology

amber system

d by the top

ows how the

ning the com

mall amount

ng on the ap

t.

mately 120°C

ssing the foo

C). It is not

er on the IR

B).

s) the compo

0°C before m

g the compon

nt of flux und

mately 120°C

ssing the foo

C). It is not

er on the IR8

s) the compo

80°C before

do I move it

to 30mm w

taking abou

ows:

tions:

e, followed b

y PCB. The t

m. The botto

heater, and

e energy is a

mponent site

of gel flux (

pplication, y

C (as measu

otswitch) for

so easy to m

810 control

onent allowin

moving the P

nent site to

der/around t

C (as measu

otswitch) for

so easy to m

810 controlle

onent allowin

moving the

for rework?

when removin

ut one secon

by a reflow s

top heat is d

om heater de

75% of the

applied to a c

e to be rewo

(approx. 0.1

you may be r

ured by the I

r the reflow

measure tem

ler to limit t

ng the joints

PCB.

be reworked

the compone

ured by the I

r the reflow

measure tem

er to limit th

ng the joints

PCB.

ng compone

d for each sc

©

Velleman

stage. The

derived from

elivers a

energy is

component.

rked over th

- 0.15mm)

required to

IR sensor).

phase to hea

mperature

he reflow

s to fully bon

d over the

ent.

IR sensor).

phase to hea

mperature

he reflow pha

s to fully bon

nts.

can of the

n nv

a

he

at

nd.

at

ase

nd.

Содержание VTSDIR

Страница 1: ...V IN US VTSD NFRA RE SER MAN DIR ED SMD UAL BGA RE EWORK S 3 STATION N ...

Страница 2: ...VTSDIR 21 03 2011 Velleman nv 2 Main station front panel Main station rear panel Figure ...

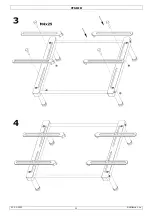

Страница 9: ...VTSDIR 21 03 2011 Velleman nv 9 Place the metal grid and secure it with the two screws X ...

Страница 10: ...VTSDIR 21 03 2011 Velleman nv 10 Appendix 2 ...

Страница 11: ...VTSDIR 21 03 2011 Velleman nv 11 ...