12

4 Mounting

VEGACAP 67 • Two-wire

31317-EN-200929

4 Mounting

4.1 General instructions

Note:

For safety reasons, the instrument must only be operated within the

permissible process conditions. You can find detailed information on

the process conditions in chapter "

Technical data

" of the operating

instructions or on the type label.

Hence make sure before mounting that all parts of the instrument ex-

posed to the process are suitable for the existing process conditions.

These are mainly:

•

Active measuring component

•

Process fitting

•

Process seal

Process conditions in particular are:

•

Process pressure

•

Process temperature

•

Chemical properties of the medium

•

Abrasion and mechanical influences

In general, VEGACAP 67 must be mounted vertically. The instrument

must be mounted in such a way that the probe is at the height of the

requested switching point.

Before beginning the welding work, remove the electronics module

from the sensor. By doing this, you avoid damage to the electronics

through inductive coupling.

Ground the probe before welding directly on the rod or cable.

Devices with threaded fitting are screwed into the process fitting with

a suitable wrench via the hexagon.

See chapter "

Dimensions

" for wrench size.

Warning:

The housing or the electrical connection may not be used for screw-

ing in! Depending on the device version, tightening can cause dam-

age, e. g. to the rotation mechanism of the housing.

With threaded versions, the housing must not be used to screw in the

instrument! Applying tightening forces on the housing can damage its

internal parts.

Use the hexagon for screwing in.

Use the recommended cables (see chapter "

Connecting to power

supply

") and tighten the cable gland.

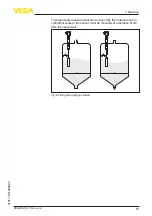

You can give your instrument additional protection against moisture

penetration by leading the connection cable downward in front of the

cable gland. Rain and condensation water can thus drain off. This

Process conditions

Switching point

Welding work

Screwing in

Handling

Moisture