7

2 Product description

MINITRAC 31 • Foundation Fieldbus

62076-EN-190704

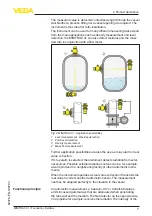

The measured value is detected contactlessly right through the vessel

wall. Neither a process fitting nor a vessel opening are required. The

instrument is thus ideal for retro installation.

The instrument can be used for many different measuring tasks. Apart

from the main applications such as density measurement and level

detection, the MINITRAC 31 can also detect residues and the mass

flow rate in conjunction with a flow meter.

1

2

3

4

Fig. 2: MINITRAC 31 - Application possibilities

1 Level measurement - Residue detection

2 Point level detection

3 Density measurement

4 Mass flow measurement

Further application possibilities are also the use as X-ray alarm or real

value correction.

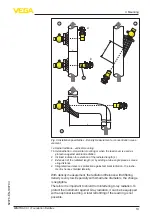

If X-ray alarm is selected, the instrument detects radiation from exter-

nal sources. Possible external radiation sources can be, for example,

a weld joint test in a neighbouring facility or other radiometric instru-

ments.

When the instrument operates as real value correction it transmits the

real value to correct another radiometric sensor. The measurement

can thus be adapted perfectly to the situation in the vessel.

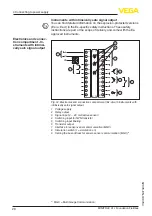

In radiometric measurement, a Caesium-137 or Cobalt-60 isotope

emits focussed gamma rays that are attenuated when penetrating

the tube wall and the medium. The NaI detector on the opposite side,

on a pipeline for example, receives the radiation. The intensity of the

Functional principle