25

5 Set up with the display and adjustment module

MINITRAC 31 • Foundation Fieldbus

62076-EN-190704

Prerequisites

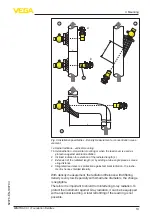

The following requirements must be fulfilled for reliable and safe

operation:

•

The tube must be filled. There must be no air bubbles in the tube

•

The source container is switched on

•

A sample point is close to the measuring point

Warning:

When the source container is switched on, the tube must always be

filled. If the tube is empty, there can be an increased local dose rate.

Make sure that the tube is filled even in case of plant downtime, or

switch the source container off.

Carry out a setup in the sequence described in the following.

Caution:

During the first setup or after an instrument reset the instrument starts

with preset standard values. These value are not suitable for your ap-

plication and must be replaced by real values.

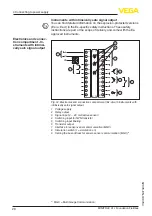

5.2.1 Setup

Enter here, the respective application.

This menu item enables adaptation of the sensor to the requested ap-

plication. You can choose between the following applications: "

Level

",

"

Density

", "

Limit level

", "

X-ray alarm

" or "

Real value correction

".

In this menu item you can enter the measuring range (min. and max.

process value) of the sensor.

These settings influence the current output of the sensor.

Enter in the menu window "

Max. process value

" the max. density

value, for example in "

g/cm

3

". This corresponds to an output current

of 20 mA.

Enter in the menu window "

Min. process value

" the min. density value,

for example in "

g/cm

3

". This corresponds to an output current of 4 mA.

Instrument start

Application

Adjustment