1101

Illustrations may differ from actual product

Subject to printing/proofreading errors

1 2

Startup

Before starting the burner for the first time, check that:

• it has been installed according to the instructions.

• the feed auger's inclination is 40 ±5°.

• there is a draught damper and it is adjusted to -5 Pa.

• all control units are correctly set.

• the burner has sufficient combustion air.

• there are pellets up to the burner.

• the grate is in the correct position and the lip is in place.

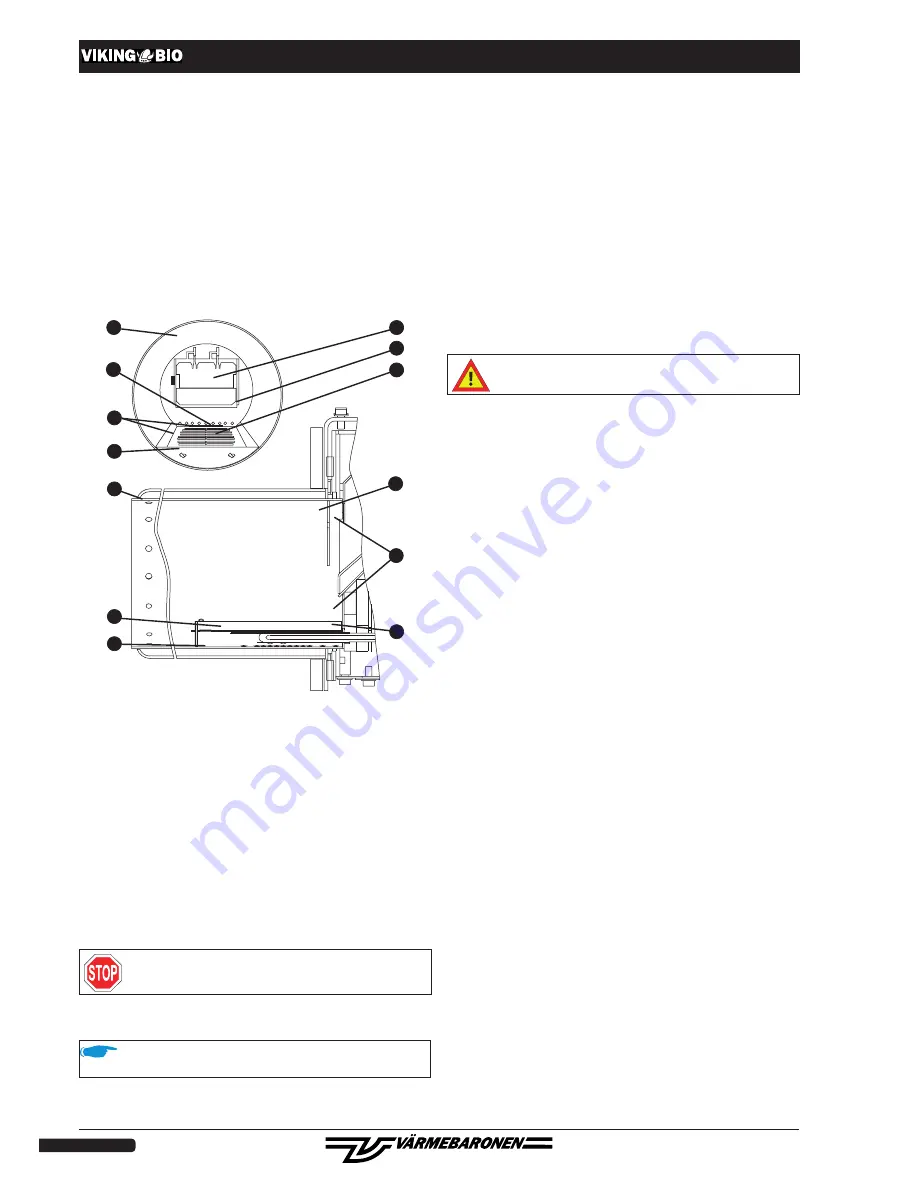

Position of grate

The grate must be positioned as shown in the figures below. If the grate is

in the wrong position, the ignition time is extended or ignition may fail. The

ignition element may also be damaged.

a

b

c

d

c

d

e

e

f

f

g

g

h

a. Cross-section, inner burner

pipe at front edge of grate.

b. Cross-section, burner

pipes in their longitudinal

direction.

c. End wall.

d. Grate.

e. Lip. Prevents pellets from bouncing out

into the combustion chamber/reduces

heat radiation.

f. The grate must be in contact with the

end wall. There must be a small gap at

its rear edge.

g. The grate must be in contact with the

burner pipe.

h. Gap.

Feed auger

The feed auger must be filled before the burner is started. This is done by

connecting the feed auger to an earthed wall outlet. Place a collection re-

ceptacle below the hose and operate the feed auger so that 25-30 litres of

pellets pass through.

Risk of crushing!

Do not insert hands or objects in the feed auger.

Draught requirements

The chimney must be fitted with a draught damper that is ap-

propriate for the chimney.

For good operating economy and reliable ignition, the chimney draught

should be

≤

5 Pa. Under certain circumstances, the draught may be difficult

to adjust. The chimney draught affects the time it takes for the burner to

establish a flame. Switch SW2/2 is used to set the draught.

Flue gas temperature

Condensation damage can be avoided if the flue gas temperature is mini-

mum 70 °C one metre below the top of the chimney. A low flue gas tem-

perature results in higher efficiency but this must be weighed up against

the risk of condensation. The temperature is measured when the boiler is

at its normal operating temperature no earlier than five minutes after the

burner was started and with the draught damper closed.

Measures to increase the flue gas temperature:

• remove any turbulators or baffle plates in the boiler.

• insulate the boiler's flue pipe and the chimney in cold rooms.

• increase the capacity of the burner

• install flue lining tubes

To avoid damage to the chimney, the flue gas temperature

must be checked.

Turbulators

Certain boiler types have or can be fitted with flue gas turbulators. Their

task is to make the flue gases turbulate to extract more heat and thus in-

crease efficiency.

At low burner power, the flue gas temperature is low and there is a risk of

condensation forming in the chimney. Try to shorten the turbulators until a

suitable flue gas temperature is obtained.

Smoke in boiler room

If the system's hatches and dampers are not airtight, there is a risk of

smoke entering the boiler room, in particular if excess pressure is formed

in the combustion chamber. A smoke detector is a good way of discovering

whether flue gases are leaking out into the boiler room.

The boiler hatches must be closed when the burner is in operation.

Combustion values

Correct adjustment is important for good heating economy, high efficiency,

low emissions of environmentally hazardous substances and the service

life of the parts of the burner in contact with the flame. Optimum adjust-

ment is possible only using flue gas analysis instruments. The boiler room

door must be closed during measurement.

The values indicate how combustion should be. Please note that the values

vary somewhat during the firing phase:

Flue gas temperature:

160 °C (depending on chimney type)

Efficiency:

>90%

CO content:

<300 ppm

CO2 content, average:

12.5% ( ±2.5%)

Boiler temperature:

60-80 °C

Soot number:

1-3.