Page 8

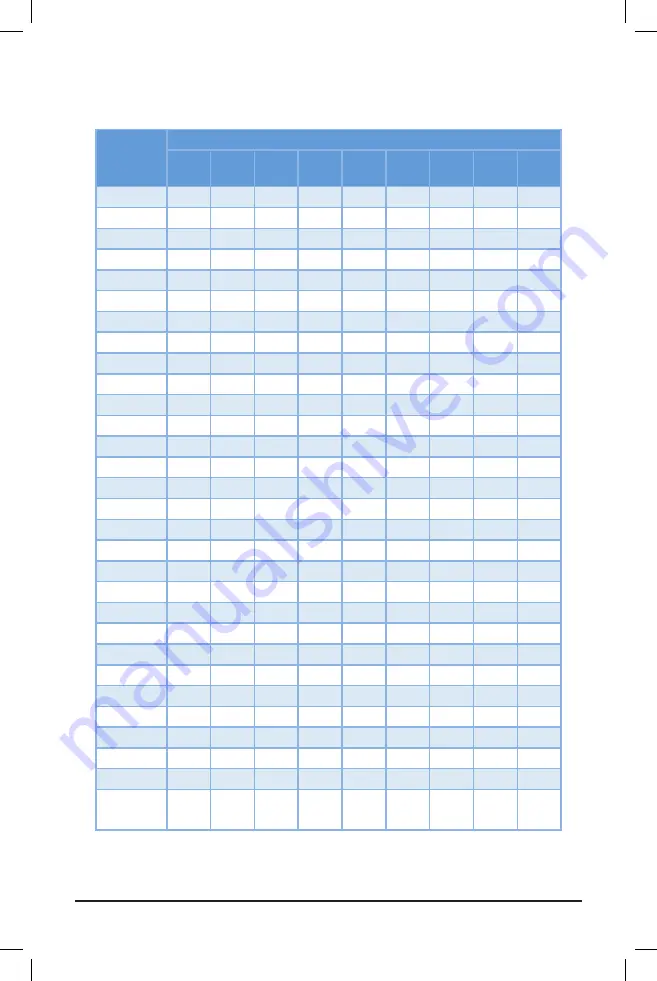

FiO2

(%)

Maximum Precision Flow Rate (L/min)

Sea

Level

1,000

ft

2,000

ft

3,000

ft

4,000

ft

5,000

ft

6,000

ft

7,000

ft

8,000

ft

21%

40

40

40

39

37

34

32

30

28

22%

40

40

40

39

37

35

33

30

28

23%

40

40

40

40

38

35

33

31

29

24%

40

40

40

40

38

36

34

31

29

25%

40

40

40

40

38

36

34

31

30

26%

40

40

40

40

39

36

34

32

30

27%

40

40

40

40

39

37

35

32

30

28%

40

40

40

40

40

37

35

33

31

29%

40

40

40

40

40

38

36

33

31

30%

40

40

40

40

40

38

36

33

31

31%

40

40

40

40

40

39

37

34

32

32%

40

40

40

40

40

39

37

34

32

33%

40

40

40

40

40

40

38

35

33

34%

40

40

40

40

40

40

38

35

33

35%

40

40

40

40

40

40

38

36

34

36%

40

40

40

40

40

40

39

36

34

37%

40

40

40

40

40

40

40

37

34

38%

40

40

40

40

40

40

40

37

35

39%

40

40

40

40

40

40

40

38

35

40%

40

40

40

40

40

40

40

38

36

41%

40

40

40

40

40

40

40

39

36

42%

40

40

40

40

40

40

40

39

37

43%

40

40

40

40

40

40

40

40

38

44%

40

40

40

40

40

40

40

40

38

45%

40

40

40

40

40

40

40

40

39

46%

40

40

40

40

40

40

40

40

39

47%

40

40

40

40

40

40

40

40

40

48%

40

40

40

40

40

40

40

40

40

49%

40

40

40

40

40

40

40

40

40

50% or

Greater

40

40

40

40

40

40

40

40

40

3100772 Rev E

Содержание Q50

Страница 1: ...Q50 Compressor Instructions for Use...

Страница 2: ......