SECTION 3: INSTALLATION

RELIANT RS45 AIR COMPRESSOR

PAGE - 10

090126-OP_r0 (JAN-2018)

VANAIR MANUFACTURING, INC.

(844) VAN-SERV • www.vanair.com

• An in-line filter on the return line is

needed to protect the system against

contaminants being introduced into the

oil. The filter should be mounted

externally from the reservoir in a location

that allows for easy of service access.

• A breather and fill cap is needed at the

oil fill port, which needs to be located

above the system oil level. The breather

cap acts to both filter air that is drawn

into the reservoir as the oil level

diminishes, and bleeds air out as the

level is regained. This maintains

constant atmospheric pressure in the air

volume within the reservoir.

• A sight-glass provides a direct visual

indication of the oil level without having

to open, or otherwise access, the

reservoir.

3.4.2.4 RECOMMENDED RESERVOIR

OPTIONS

Although not essential for an adequately

functioning

reservoir,

the

following

components will contribute to maximize the

hydraulic system’s efficiency and maintain a

quality operational level.

• Magnetic drain plug: Attracts and

concentrates ferrous contaminants at the

drain plug source for easier accessibility

and removal when cleaning tank interior.

• A temperature gauge: Located in

approximation to, or built in to, the sight

glass assembly allows for temperature

reading at a glance.

• Filler port strainer: Prevents large

contaminant particles from blending with

system oil when adding new oil.

• Return line diffuser (splash) plate reduces

velocity of oil flow before return oil

stream merges with the main reservoir

oil volume.

• A reservoir heater: For those systems that

are exposed to cold climate ambients,

having the ability to preheat the hydraulic

oil prior to start up will make for easier

startups, and reduce the strain of

warming up the system under adverse

cold conditions.

3.4.2.5 RESERVOIR FEATURES TO

AVOID

A strainer used to screen the suction line is

not recommended for systems designed for

mobile equipment use. Having equipment

that likely experiences long suction lines,

cold startups and non-tracked or infrequent

maintenance practices may cause this

strainer to potentially promote system strain

(cavitation) than prolong fluid integrity

through filtration.

A pressurized reservoir is not recommended

for vehicles, as its complexity invites too

much potential for loss of system reliability if

it is not properly maintained.

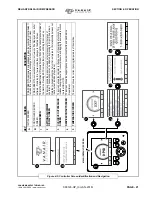

3.4.3 RECOMMENDED HYDRAULIC

SYSTEM SPECIFICATIONS

Refer to

Figures 3-3A

through

3-3D

.

• Flow controller is optional to reduce flow if

necessary. Consult Vanair

®

.

HYDRAULIC LINES

The following is a minimum requirement and

NO quick disconnects may be used. Lines

are to be kept as straight and short as

possible.

• Pressure port = Standard, #12, 3/4” hose

(located at manifold block)

• Load sense = #4 JIC = 1/4” hose (Used for

closed center system only)

• Pressure relief/case drain = #6 JIC = 3/8”

hose

• Hydraulic suction = Standard, #16, 1”

hose

3.4.4 STANDARDS GUIDELINES

• Hydraulic pressure relief factory set at

3200 psi.

WARNING

Do not operate machine without hydraulic

system completely assembled.

Содержание Reliant RS45

Страница 86: ...BLANK PAGE...

Страница 87: ...BLANK PAGE...