9

1.4.2 Road transport

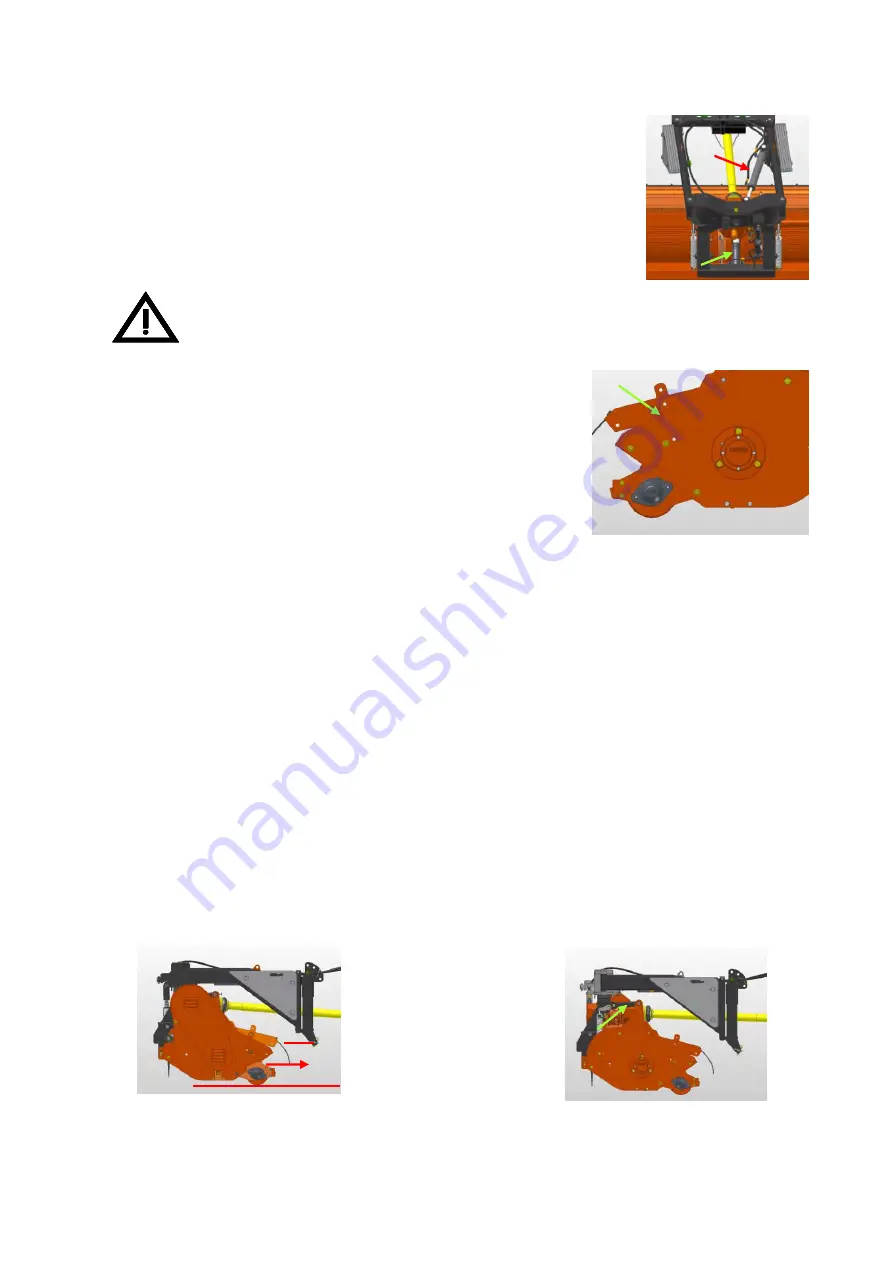

During road transport, the flail mower must with the parallelogram(red arrow) arms be

positioned in the middle of the tractor. Then lock the machine oscillating by pressing

the cylinders (green arrow) on (hydraulic) pressure, so that it is pressed against the

buffers.

During road-transport the machine is carried by the tractor 3-point linkage. It is not allowed to

carry the machine in offset position during road-transport!

1.4.3 Cutting height

The cutting height can, if necessary, be adjusted with the rear roller as follows:

By re-setting the upper fixing bolts in one of the other adjusting holes of the

frame and / or adjusting plate. The highest hole in the frame will give you the

lowest cut ± 40 mm (1,6") and the lowest hole in the frame the highest cut ± 100

mm (3,94 ).

The machine front-side should always be carried by the tractor 3-point linkage.

1.4.4 P.T.O. shaft

The P.T.O. shaft supplied with the machine has a retracted length of 1610 mm (± 5'3”).

This length is correct for most of the popular tractor sizes. However it is strongly recommended to check the proper

length of the P.T.O. shaft before operating the machine, and if necessary to shorten it according to the instructions

attached to the P.T.O. shaft. Check the proper length as well in transport- as in work positions!

Check the length of the overlap of the protection elements; this should be at least 50 mm (2”).

The guard tube of the P.T.O. shaft must be secured against rotation by the little chains.

When the machine is disconnected from the tractor the P.T.O. shaft should rest in the corresponding chain of the 3-point

bow.

Remark: Using an oversized tractor (over 80HP) it is strongly recommended to install an overload clutch.

This clutch should be adjusted at the following value:

- KT-245, -270 and -300, P.T.O. Speed 1000 RPM 1200 Nm ( 10.621 inlb.)

-

KT-320, P.T.O. Speed 1000 RPM 1500 Nm ( 13.276 inlb.)

1.4.5 Adjusting work position

During work, the machine must be adjusted in a free-moving position. This can be achieved by adjusting the height

of the lifting arm pins at +/- 50cm from the bottom (red arrow). The machine must be adjusted flat by the top link,

so that the parallelogram system is horizontal and has a free movement of +/- 15cm (green arrow).