16

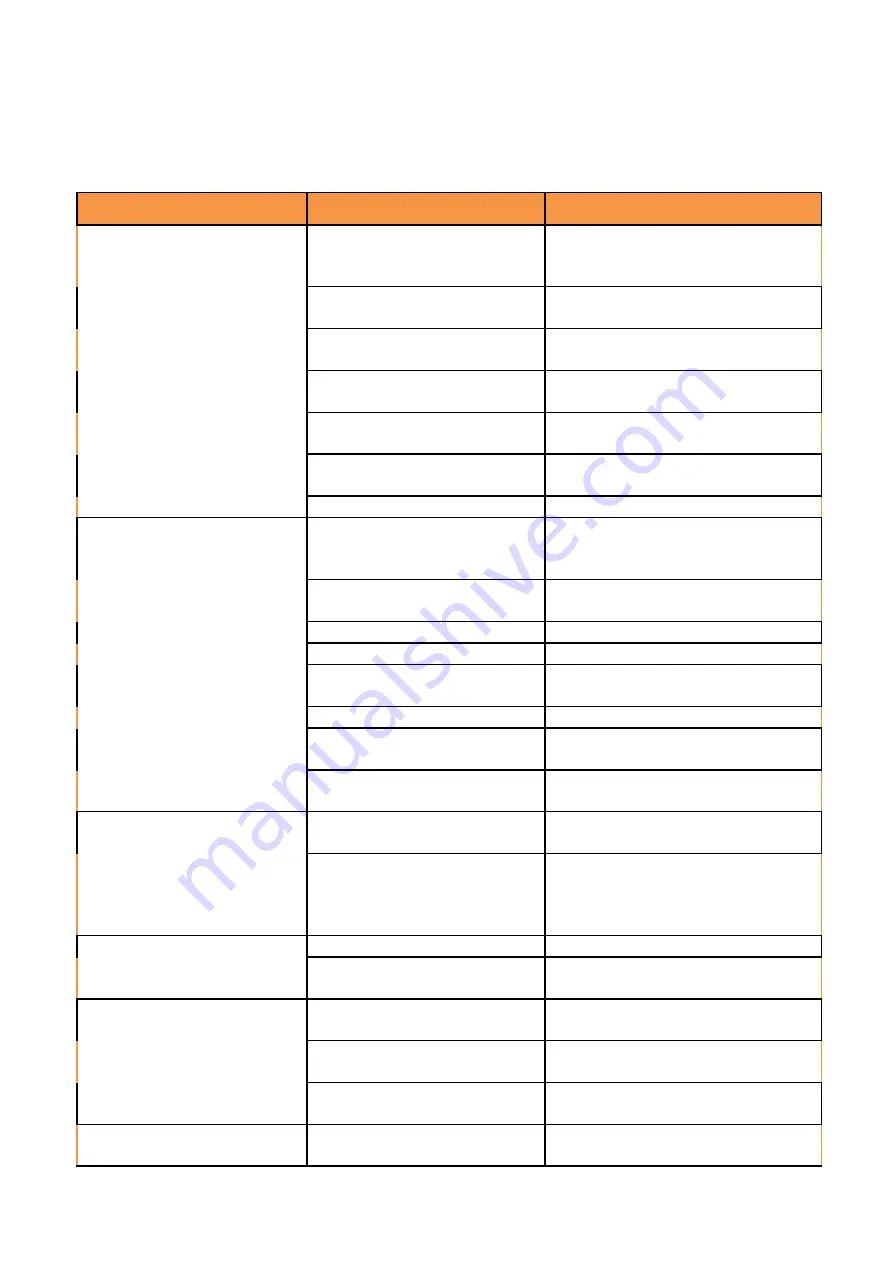

1.12 Storingstabel

As a result of normal use, parts will be wear out. (for example Flails and V-belts).

Pay Attention

: only use original "PERFECT" parts that are listed in the parts book.

Failure

Causes

Solution

Strong vibration and too much

noise

Flails not evenly worn out

Change flails, complete with bolt and

nut as a pair or as complete set

(more) Flails are fixed and don

’

t

move

Clean the Machine so that the flails

can be move.

One or more flails are lost or

broken

Change flails.

Thread or other stuff wrapped

around the flail rotor.

Remove pollution

Flail rotor not in balans

Check the rotor / bearings and when is

necessary, must it be balanced

Bearings of Flail rotor are worn

out

Change bearings and / or flails

PTO shaft isn

’

t in line

Change PTO shaft

Machine and or mow quality

won

’

t work very well

Machine isn

’

t horizontal

adjusted with the bottom

Check rear roller and / or upper

linkage adjustment. When is necessary

add it in the correct way

Flails are worn out

Klepels compleet met bouten en

moeren vervangen

Speed flail rotor too low

Increase PTO speed

Rijsnelheid te hoog

Reduce speed

V-belt tension too low

Check V-belt tension and retension if

necessary

V-belt is worn out

Change complete set V-belts

Cutting height too low adjusted

Check rear roller adjustment and

change that when necessary

Cutting height too high adjusted

Check rear roller adjustment and

change that when necessary

Flail rotor won

’

t rotate

Flail rotor is stuck through

pollution

Remove dirt and clean the machine

Overrunning clutch in PTO shaft

or Gearbox is wrong or broken.

PTO goes constantly through

overrunning.

Change overrunning clutch PTO shaft

or gear box

PTO shaft runs, but flail rotor

don

’

t

V-belt broken

Change set V-belts

Overlaoding clutch (Optional) is

wrong adjusted or worn out

Adjust the spring package correctly or

change the clutch plates

Rear roller turns heavily or is

blokked

Rear roller bearings broken or

filled with mud

Changes bearings and grease these to

the correct level

Running dry, without grease

Grease bearings until the grease

comes outside

Dirt between roller and scraper

Remove dirt and clean the machine

V-belt problems ( too much

belts are worn out, belts burns

V-belts not correct adjusted

Check V-belt adjustment and when

needed adjust it correctly