ENGLISH

MD 950

/ NanoPak

Data input

Chapter 3

Page GB 22

9.694.038

V 4.02

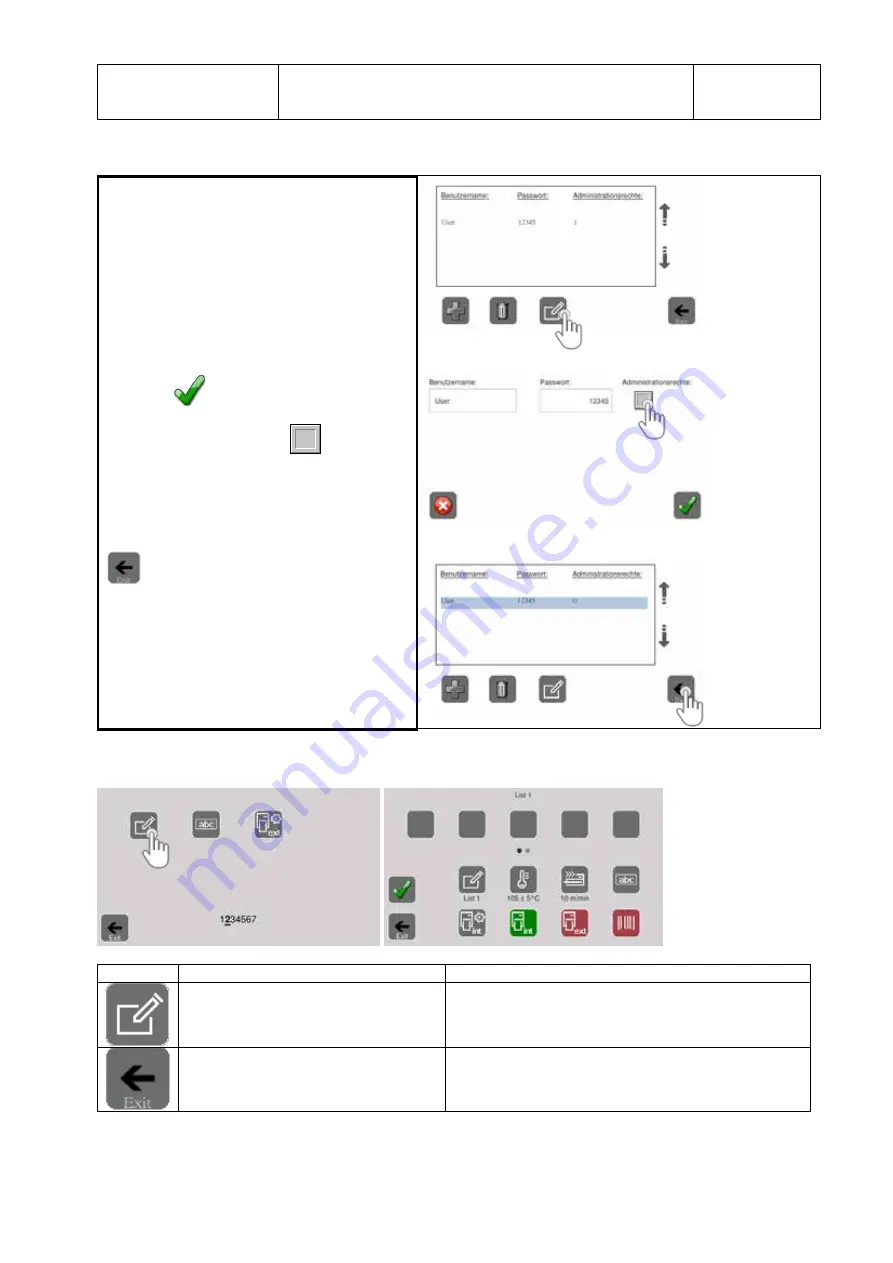

3.2.3 Removing administrator rights

1. Select a user name,

e.g. "User"

2

.

Press the symbol to edit selected user data.

3. Remove the administrator data and confirm by

pressing the

key.

Administrator rights inactive

Exit this menu level

3.3 Packaging lists

Menu

Key

Function

Note

Select the packaging list menu

Exit menu level

back to the home screen