Appendix

0020230535_05 ecoFIT pure Installation and maintenance instructions

29

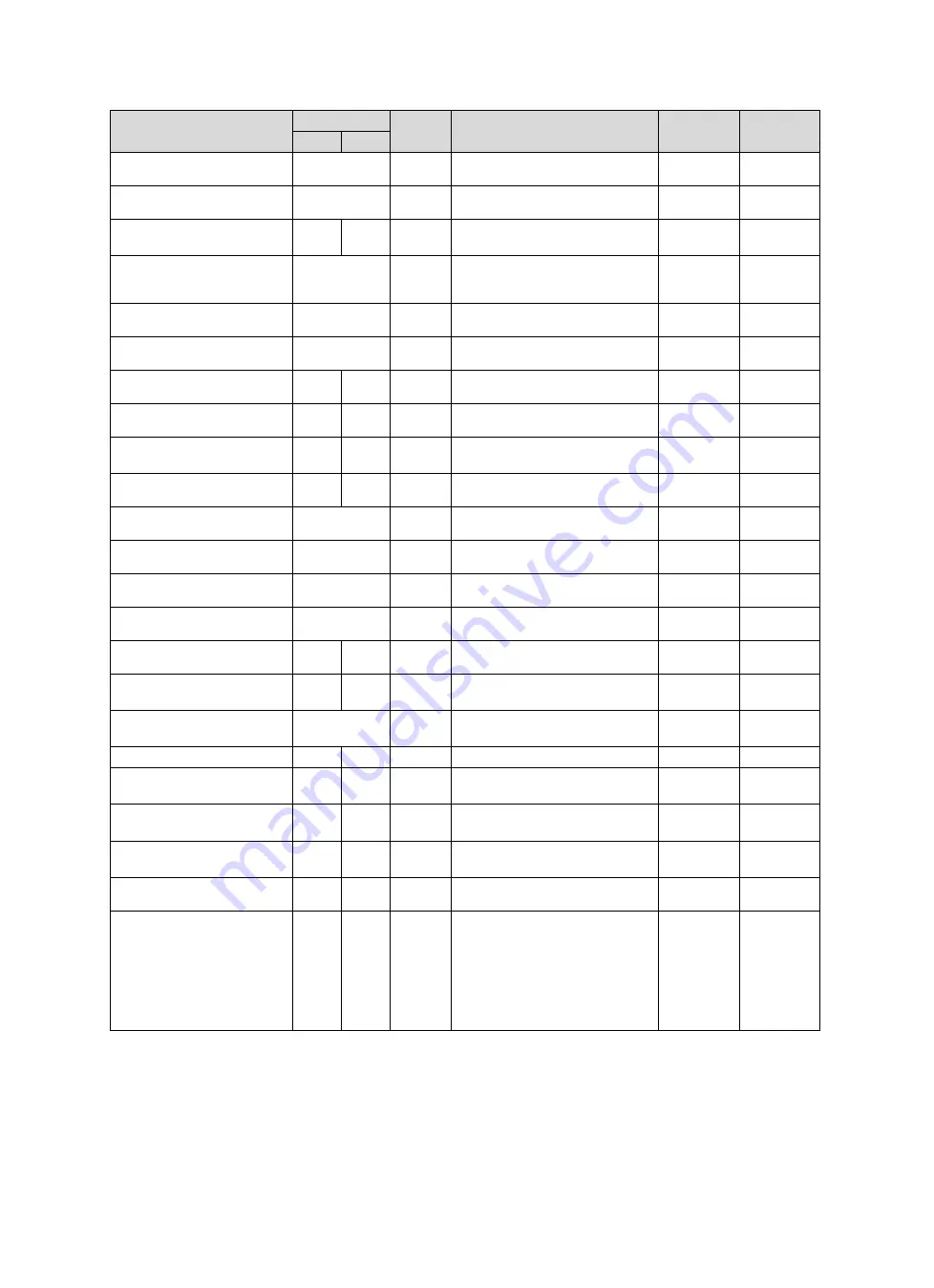

Setting level

Values

Unit

Increment, select, explanation

Default set-

ting

Own setting

Min.

Max.

d.64 Average burner ignition

time

Current value

s

–

–

Not

adjustable

d.65 Maximum burner ignition

time

Current value

s

–

–

Not

adjustable

d.66 Activation of the warm

start function for hot water

–

–

–

off = Function deactivated

on = Function activated

1

Adjustable

d.67 Remaining burner anti-

cycling time (setting under

d.02)

Current value

min

–

–

Not

adjustable

d.68 Number of unsuccessful

ignitions at 1st attempt

Current value

–

–

–

Not

adjustable

d.69 Number of unsuccessful

ignitions at 2nd attempt

Current value

–

–

–

Not

adjustable

d.71 Maximum heating flow set

target temperature

45

80

℃

1

75

Adjustable

d.75 Maximum cylinder reheat-

ing time

20

90

min

1

45

Adjustable

d.77 Max. cylinder reheating

–

–

kW

1

→

Section "Technical data"

–

Adjustable

d.78 DHW max. flow temperat-

ure

50

80

℃

1

–

Adjustable

d.80 Running time in heating

mode

Current value

h

–

–

Not

adjustable

d.81 Running time in DHW

mode

Current value

h

–

–

Not

adjustable

d.82 Number of burner igni-

tions in heating mode

Current value

–

Number of ignitions = Display value x

100

–

Not

adjustable

d.83 Number of burner igni-

tions in DHW mode

Current value

–

Number of ignitions = Display value x

100

–

Not

adjustable

d.84 Maintenance in

0

3000

h

Number of hours = Display value x 10

300

Not

adjustable

d.85 Increase in the min. out-

put (heating and DHW mode)

–

–

kW

1

→

Section "Technical data"

–

Adjustable

d.90 Status of the eBUS room

thermostat

Current value

–

off = Not connected

on = Connected

–

Not

adjustable

d.93 Setting the product code

0

99

–

1

–

Adjustable

d.94 Delete fault list

0

1

–

off = No

on = Yes

–

Adjustable

d.95 Software versions

–

–

–

1 = Main PCB

2 = Interface PCB

–

Adjustable

d.96 Reset to factory setting

–

–

–

0 = No

1 = Yes

–

Adjustable

d.128 Heating minimum target

value

10

75

℃

1

10

Adjustable

d.129 Hot water minimum tar-

get value

35

(com-

bina-

tion

unit)

45

(pure

boiler)

60

℃

1

35

Adjustable