Adapting the unit to the heating installation 8

0020230535_05 ecoFIT pure Installation and maintenance instructions

19

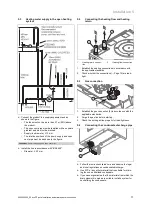

▶

Allow the boiler to cool down by allowing pump overrun

to operate for a minimum of two minutes.

▶

Close the gas stopcock.

▶

Remove the pressure gauge and retighten the sealing

screw

(2)

for the measuring nipple.

▶

Open the gas stopcock

(1)

.

▶

Check the test nipple for gas tightness.

▶

Close the gas stopcock

(1)

.

▶

Install the front casing. (

→

Page 9)

▶

Disconnect the product from the electrical installation.

▶

You must not start up the boiler.

Conditions

: Gas flow pressure

in the

permissible range

▶

End the check programme

P.01

.

▶

Allow the boiler to cool down allowing pump overrun to

operate for a minimum of two minutes.

▶

Close the gas stopcock

(1)

.

▶

Remove the pressure gauge and retighten the sealing

screw

(2)

for the measuring nipple.

▶

Open the gas stopcock

(1)

.

▶

Check the test nipple for gas tightness.

▶

Remove the front casing. (

→

Page 9)

▶

Reset boiler controls for normal operation.

▶

Record the appliance gas inlet working pressure (kPa

resp. mbar) in the Benchmark gas boiler commissioning

checklist.

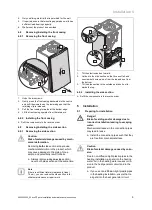

7.8.2

Checking the leak-tightness of the flue gas

installation and flue gas recirculation

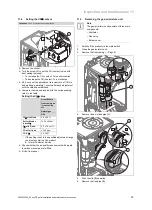

1.

Check the flue gas installation is intact in accordance

with the latest gas safe technical bulletin and informa-

tion supplied in the installation instructions.

2.

For extended flue gas installations check for flue gas

recirculation using the air analysis point.

3.

Use a flue gas analyser.

4.

If you discover CO or CO

2

in the supply air, search for

the leak in the flue gas installation or for signs of flue

gas recirculation.

5.

Eliminate the damage properly.

6.

Check again whether the supply air contains any CO or

CO

2

.

7.

If you cannot eliminate the damage, do not start up the

product.

7.8.3

Checking the CO

₂

content

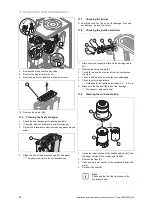

1.

Start up the product with check programme

(P.01)

.

Overview of the check programmes (

→

Page 16)

2.

Wait until the value that is read is stable.

–

Waiting period for reading a stable value: 5 min

1

3.

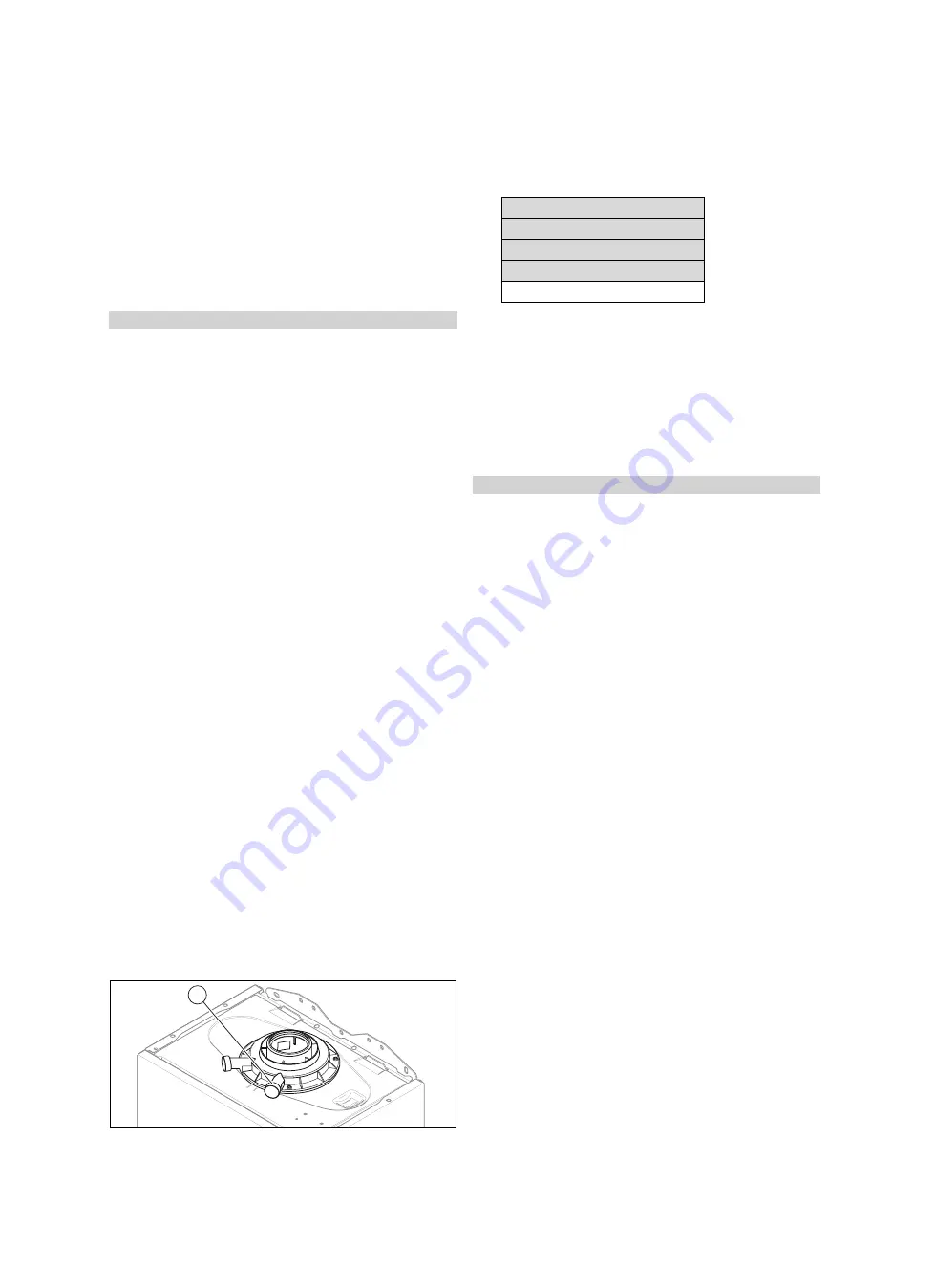

Unscrew the cover from the flue gas analysis point

(1)

.

4.

Measure the CO

₂

content at the flue gas analysis point

(1)

.

5.

Compare the measured value with the corresponding

value in the table.

Checking the CO

₂

content

Great Britain

front casing on / front casing off

Natural gas

G20

9.2

±

1 %

◁

The value is OK.

▽

The value is not OK; you cannot start up the

product.

▶

Inform Customer Service.

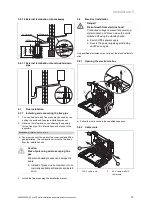

7.9

Checking leak-tightness

▶

Check the gas pipe, the heating circuit and the hot water

circuit for leak-tightness.

▶

Check that the air/flue pipe has been installed correctly.

Conditions

: Room-sealed operation

▶

Check whether the vacuum chamber has been closed

tightly.

7.10

Checking the heating mode

1.

Activate the heating mode on the user interface.

2.

Turn all thermostatic radiator valves on the radiators

until they are fully open.

3.

Allow the product to operate for at least 15 minutes.

4.

Purge the heating installation.

5.

Call up the

Live Monitor

.

–

Menu

→

Live Monitor

Status codes

–

Overview (

→

Page 30)

◁

If the product is working correctly, the display shows

S.04

.

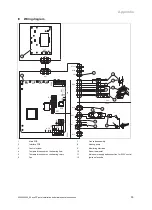

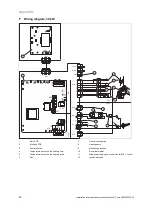

8

Adapting the unit to the heating

installation

You can reset/change the system parameters (section "Us-

ing diagnostics codes").

Overview of diagnostics codes (

→

Page 27)

8.1

Burner anti-cycling time

To prevent frequent switching on and off of the burner and

thus prevent energy losses, an electronic restart lockout

is activated for a specific period each time the burner is

switched off. The burner anti-cycling time is only active for

the heating mode. Hot water handling mode during a burner

anti-cycling time does not affect the time function element.