GAS COMPRESSORS / BOOSTERS

GAS & AIR MIXING SYSTEMS

AIR BLOWERS & VACUUM PUMPS

The Utile Engineering Co. Ltd.

Irthlingborough, Northamptonshire, NN9 5UG, ENGLAND

Telephone: + 44 (0) 1933 650216 Facsimile: + 44 (0) 1933 652738 Email: [email protected]

www.utileengineering.com

10

IC182

Maintenance

Fully trained and competent staff must carry out any maintenance work. Utile Engineering offers contract maintenance

services if required contact our service department.

When carrying out any maintenance and inspections always follow the health and safety guidelines on page 4.

A regular correct maintenance plan is essential to good operational reliability and a long service life for your machine. As

operating conditions vary, no exact timings can be specified for wear checks, repairs and inspections, however the following

plan can be used as a guide until time scales to better suit the machines environment are found.

The machine, ancillaries and surrounding area should be kept as clean as possible.

Ensure all items are properly held and supported during all aspects of maintenance as not to pose a problem for health and

safety. Observe all lifting points and apply care when handling the equipment.

Ensure all machines and associated pipework have cooled down sufficiently before touching and attempting any

maintenance.

Typical tools required for maintenance include: -

Set of spanners

Pipe Wrenches

Circlip Pliers

Set of screwdrivers

Vernier Gauge / Micrometer

Two-leg Pulley drawer

Set of Allen Keys

Hammer / mallet

Feeler Gauges

Typical bolt tightening torques can be seen on page 6.

New gaskets must be fitted every time the machine is dismantled.

Bearings and seals are recommended to be replaced after 15000 operating hours or 2 years whichever is sooner.

Blades must be replaced regardless of wear after 20000 operating hours as failure due to fatigue could cause serious

damage.

After maintenance the machine and equipment must be treated, as new and all pre-commissioning checks should be made.

Install all protective devices and controls properly after completion of work. Ensure all cabling, unions and guards are

correct, secure and in place. Dispose of any used oil and cleaning solutions as prescribed by law.

Maintenance

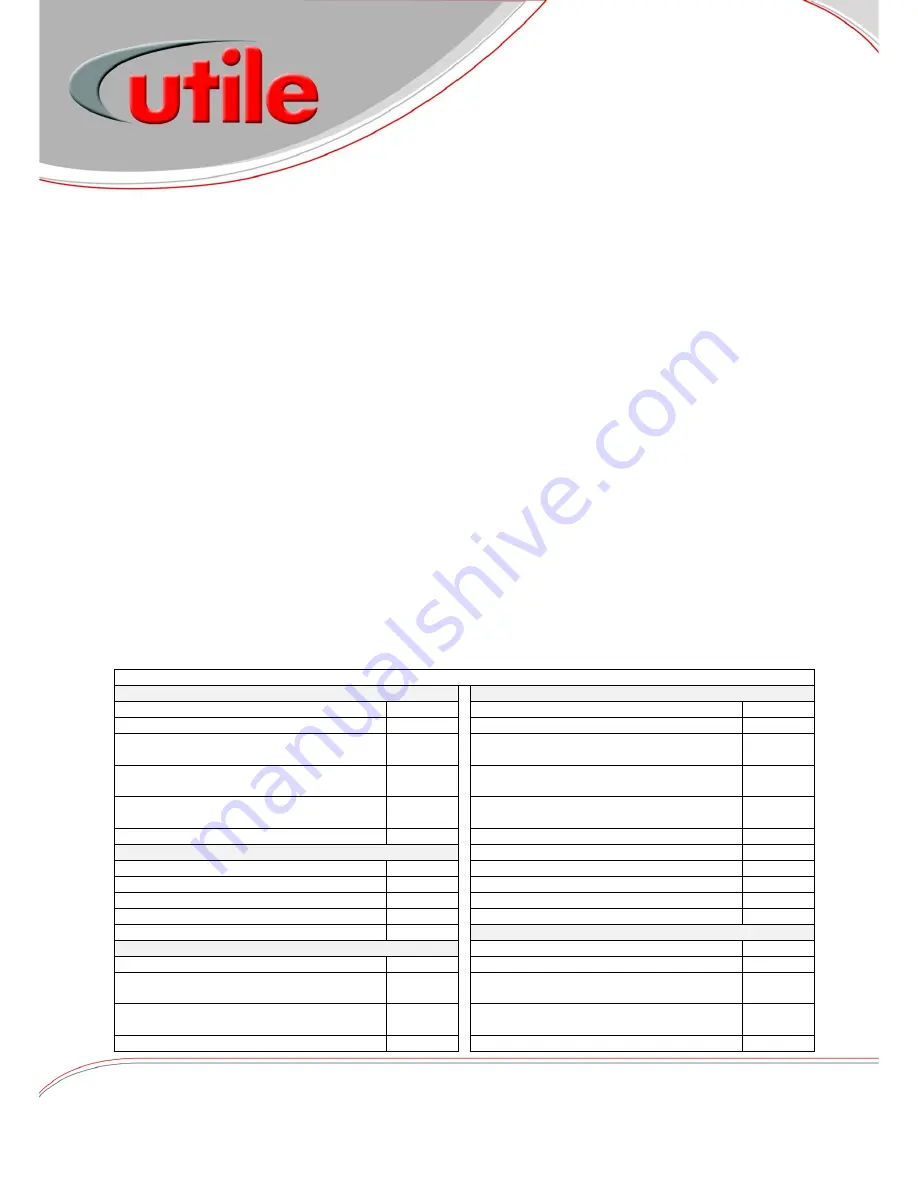

MAINTENANCE PLAN

DAILY CHECKS

QUARTERLY CHECKS

TASK

CHECK

TASK

CHECK

Check / Fill lubricator reservoir

Check machine for blade wear.

Check Belt condition/Tension (Hourly for

running in period).

Check control panel for wiring, cleanliness and

function of all panel features. (if applicable)

Drain all vessels, condensate traps, outlet

filters manually

Check function of emergency stop button and

local motor isolator. (if applicable)

Clean inlet filters (Daily for 1

st

week).

Check motors for excessive vibration and

damage.

Check function of pressure gauges.

WEEKLY CHECKS

Check function of non-return valves

Check lubricator drip rate

Check function of pressure relief valves

Check belt condition / tension

Clean inlet filters (After for 1

st

week).

Run Standby machine for a few minutes.

YEARLY CHECKS

MONTHLY CHECKS

Clean lubricator and oil lines

Check function and operation of all valves.

Check flanges and joints for leaks.

Check differential pressure across filters (clean

and replace if necessary).

Clean internally vessels, condensate traps,

filters (including elements).

Check function and operation of autodrains /

condensate lines.

Inspect machine internally (at least once a

year)

Clean fins on machine and motors