GAS COMPRESSORS / BOOSTERS

GAS & AIR MIXING SYSTEMS

AIR BLOWERS & VACUUM PUMPS

The Utile Engineering Co. Ltd.

Irthlingborough, Northamptonshire, NN9 5UG, ENGLAND

Telephone: + 44 (0) 1933 650216 Facsimile: + 44 (0) 1933 652738 Email: [email protected]

www.utileengineering.com

11

IC182

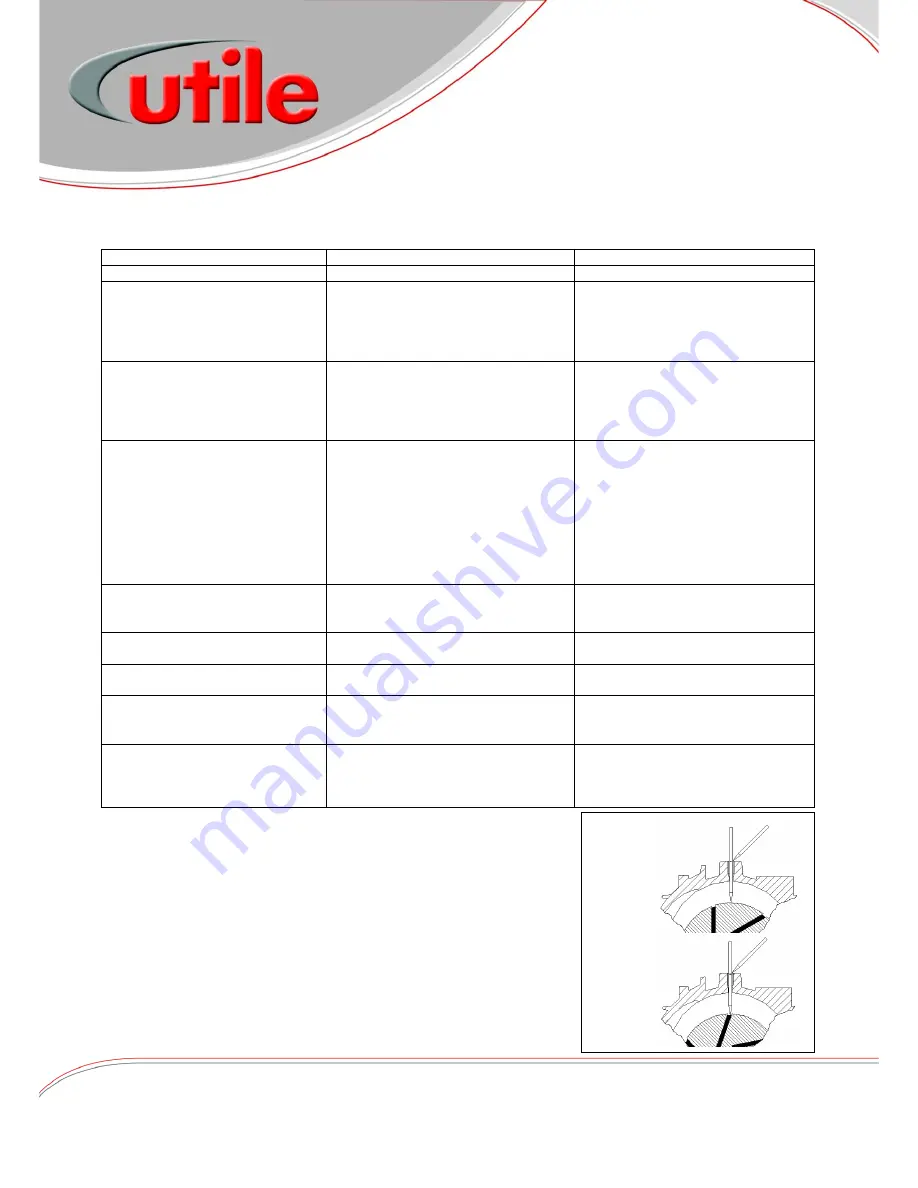

Fig. 8

Scribe mark with rod

resting on rotor, turn

rotor and scribe mark

with rod on blade

Troubleshooting

The following table shows some typical problems and the remedies.

Note: If assistance is required in determining or correcting the fault with the machine then contact our service department.

1.

Check Blade Wear

When carrying out any maintenance and inspections always follow the health and

safety guidelines on page 4. Fully trained and competent staff must carry out any

maintenance work.

1.1

Carry out the following procedure after the first 2,000 running hours

and repeat every 5,000-hour interval. Record all measurements.

1.2

With the pump stationary and with the system drained, remove the

eyebolt or plug in the top of the machine cylinder and insert into the

hole beneath a pointed measuring rod 6mm dia x 150mm long until

contact is made with the rotor (see fig. 8). Scribe a mark on the rod.

Slowly rotate the shaft by hand until the rod drops onto the tip of the

blade, scribe a second mark on the rod. Measure the amount of

movement and renew the blades if this exceeds 6mm. Replace the plug

or eyebolt.

Troubleshooting

Check Blade Wear

SYMPTONS

CAUSES

REMEDIES

Machine revolves in wrong direction

Incorrect connection of motor terminal

Re-arrange terminal connection

Discharge air temperature excessive

1. Machine operating at higher duty than

specified.

1. Check rating.

2. Blocked intake filter.

2. Clean intake filter.

3. Insufficient or wrong lubrication.

3. Use correct lubrication and feed rates.

4. Warped / Sticking blades

4. Replace blades

Excessive blade wear

1. Insufficient lubricant to cylinder.

1. Inspect & clean oil lines, oil holes.

2. Incorrect lubricant.

2. Use correct lubricant.

3. Dirty inlet air/gas.

3. Clean & inspect intake.

4. Excessive operating temperature

4. See remedies for excessive discharge

temperature.

Abnormal noise, vibration or periodic

knocking

1. Worn bearing.

1. Replace bearing.

2. Excessive blade wear.

2. Replace blades & check lubrication

3. Erratic cylinder wear.

3. Rebore, redowel & check lubrication.

4. Insufficient lubrication

4. Increase lubrication rate

5. Rotor contacting coverplates

5. Check temperature, pressure &

internal clearances

6. Drive misalignment

6. Realign and retension drive.

7. Warped rotor blades.

7. Replace rotor blades.

8. Excessive liquid carryover.

8. Drain all points.

Pressure cannot be built up or only up

to a certain extent.

1. Worn blades.

1. Replace rotor blades.

2. Improper belt tension.

2. Adjust belt tension.

3. Sticking relief valve.

3. Clean and replace.

Slipping of belts

1. Improper belt tension.

1. Adjust belt tension.

2. Worn belt.

2. Replace with new ones.

Overheating of electric motor

1.Overloading of motor due to excessive

working pressure.

1. Lower working pressure.

Machine does not start

1. Breakdown of electric current

1. Contact power company.

2. Malfunction of motor.

2. Check motor.

3. Wrong motor connections.

3. Check electrical connections.

Shaft partially or totally locked

1. Faulty bearing

1. Replace bearing.

2. Foreign particles in machine.

2. Disassemble machine and remove

foreign particles.

3. Machine seized.

3. Repair machine.