13

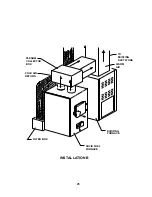

Installation

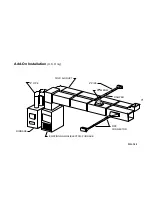

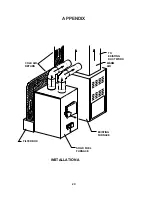

Please see all methods of Installation

in Appendix at the rear of this booklet.

This is a furnace, not a free standing stove.

You must direct heated air from 8" outlets away

from the furnace, or it will not function properly.

1. This installation must be done by a qualified

heating equipment installer.

2. The installation is to be done in compliance

with National Fire Protection Association installa-

tion standards: No. 89M, 90B, 211, 70 (National

Electric Code) and Uniform Mechanical Code

913, 6-4, in the states where applicable. (Their

code offers connecting smoke pipe connectors

into chimney with other fuel burning appliances.)

3. Rooms large in comparison with size of the

appliances:

a) Wood or Coal Burning Furnace needs air for

combustion and circulation to house.

b) Provision must be made to make up this air

and not starve gas or oil furnace of combustion

air.

c) Have "Authority Having Jurisdiction" deter-

mine that air is of adequate makeup. (Reference

N.F.P.A. Nos. 30 & 54, Code for Installation of

Gas & Oil Equipment)

4. Have "Authority Having Jurisdiction" to

inspect all chimneys and installations for ad-

equate venting and for compliance with standard

and local codes and regulations regarding instal-

lation of wood burning appliances.

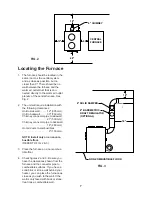

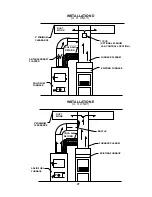

5. Installation of Supplemental Heat Applica-

tion to Existing Central System. (See Fig. 2 for

typical installation.)

a) Place Wood or Coal Burning Furnace so that

the chimney connector will be as short as pos-

sible and avoiding unnecessary sharp turns in the

smoke pipe connector and the installation of

devices that would create excessive resistance

to the flow of flue gases.

b) Locate the Wood or Coal Burning Furnace as

close as practical to the existing central hot air

heating system, maintaining clearances as stated

on the label below the fuel door.

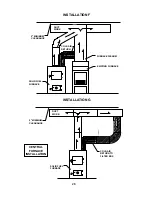

c) Clearances from combustible materials must

be complied with as stated on the label below the

fuel door:

Unit to Combustible:

Front: 48"

Back: 30"

Sides: 12"

Plenum to Ceiling: 6"

Pipe to Combustible:

Sides: 21"

Back: 18"

The installation must be made only on a

noncombustible floor.

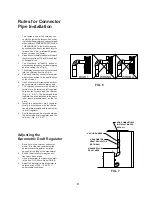

d) Install the smoke pipe connector to the

chimney with 26-gauge pipe and elbows (to be

purchased separately), maintaining the proper

clearances for the specific model. Make sure that

the proper clearances as stated on the label and

earlier in this manual are maintained. Seal the

smoke pipe in the chimney with furnace cement.

(The chimney connector shall be securely sup-

ported, and joints fastened with sheet metal

screws or rivets.)

e) Install 8" diameter heat pipe to plenum of the

central hot air furnace. Use 26-guage pipe and

connectors (to be purchased separately). (See

Fig. 14) If central air conditioning is installed in the

plenum, install heat pipe above the air condition-

ing unit. Secure heat pipe connection with sup-

ports and sheet metal screws.

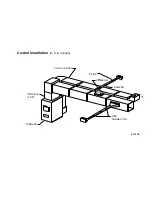

f) Connect electrical supply in the electrical

junction box that is mounted on the back of the

Wood Burning Furnace. See Wiring Diagram (Fig.

12). Remove the cover from electrical junction

box connect power supply wires to wires desig-

nated, using wire nuts. The power cord supplied

may be used for installation, if permitted by local

codes and regulations. If the power cord supplied

cannot be used, the power supply wiring must be

90 degrees Centigrade in a metal cable and

should be completed by a qualified installer com-

plying with NFPA Standard No. 70 and local

codes.

g) Optional Plenum Fan Control Switch (Part

No. 11PCS) is available for installation on the

plenum of central hot air heating furnace. The

purpose of this switch is to activate the circulating

fan of the central hot air heating furnace when the

temperature in the plenum exceeds 120 degrees

Fahrenheit. The switch would activate the fan at

120 degrees Fahrenheit, and would shut off the

circulating fan when the temperature in the ple-

num is reduced to 100 degrees Fahrenheit . This

avoids overheating the plenum.

The electrical supply for operation of this fan

control switch is to be obtained from same elec-

trical supply as the central hot air heating system.

(See Fig. 14) Follow the instructions of the wiring

diagram (Fig. 15). Do not make connections

across Limit Control in the furnace.

Make electrical connections in electrical junc-

tion box presently mounted on the furnace. Make

electrical connections in accordance with NFPA

Standard No. 70 and local codes in the power

supply junction box (See Fig. 15). The wiring to

complete the connections should be 18 AWG

minimum copper and 90 degrees Centigrade in a

cable.

Содержание Clayton 1537Q

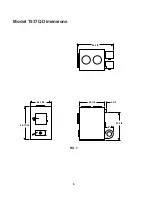

Страница 6: ...24 1 16 40 11 16 32 1 4 3 1 2 9 33 7 8 43 7 8 Model 1537Q Dimensions FIG 1 6 ...

Страница 22: ...Model 1537Q Parts 22 ...

Страница 31: ...31 Notes ...