25

Capacity Calculation

To treat the water properly, the contaminant levels will need to be known to determine the

amount of gallons that can be used between regeneration cycles. The supplied hardness

test strips can be used to determine the feed water hardness level. Once that is known,

there is a calculation that will determine the number of gallons that can be treated. Here is

that formula;

System Capacity / Hardness Level = Gallons of Capacity

The chart below can help determine the capacity.

Example;

Hardness Level: 23 GPG

EPWS - 2 System Capacity: 22,000 Grains

22,000 Grains / 23 Grains per Gallon =

957 Gallons of Capacity

This would indicate that

957

gallons of water can be treated before a regeneration cycle is

necessary.

NOTE: If there is iron in the water, add 5 GPG to the hardness level. If you have an

actual iron value or an iron test kit, add 1 GPG for every ppm of iron present.

Example;

Hardness Level: 14 GPG

Iron Present: 5 GPG

Compensated Hardness: 19 GPG

EPWS - 1 System Capacity: 10,000 Grains

10,000 Grains / (14 GPG + 5 GPG) = Gallons

10,000 Grains / 19 GPG =

526 Gallons of Capacity

This would indicate that

526

gallons of water can be treated before a regeneration cycle is

necessary.

The amount of gallons used will be determined by the end user. Either a know amount of

storage tank space can be used to calculate it or an inline water meter will be needed to

track the amount of gallons treated through the system.

NOTE: The system should be backwashed and regenerated each time a new water

source is used or the system is used after sitting dormant for a period of time.

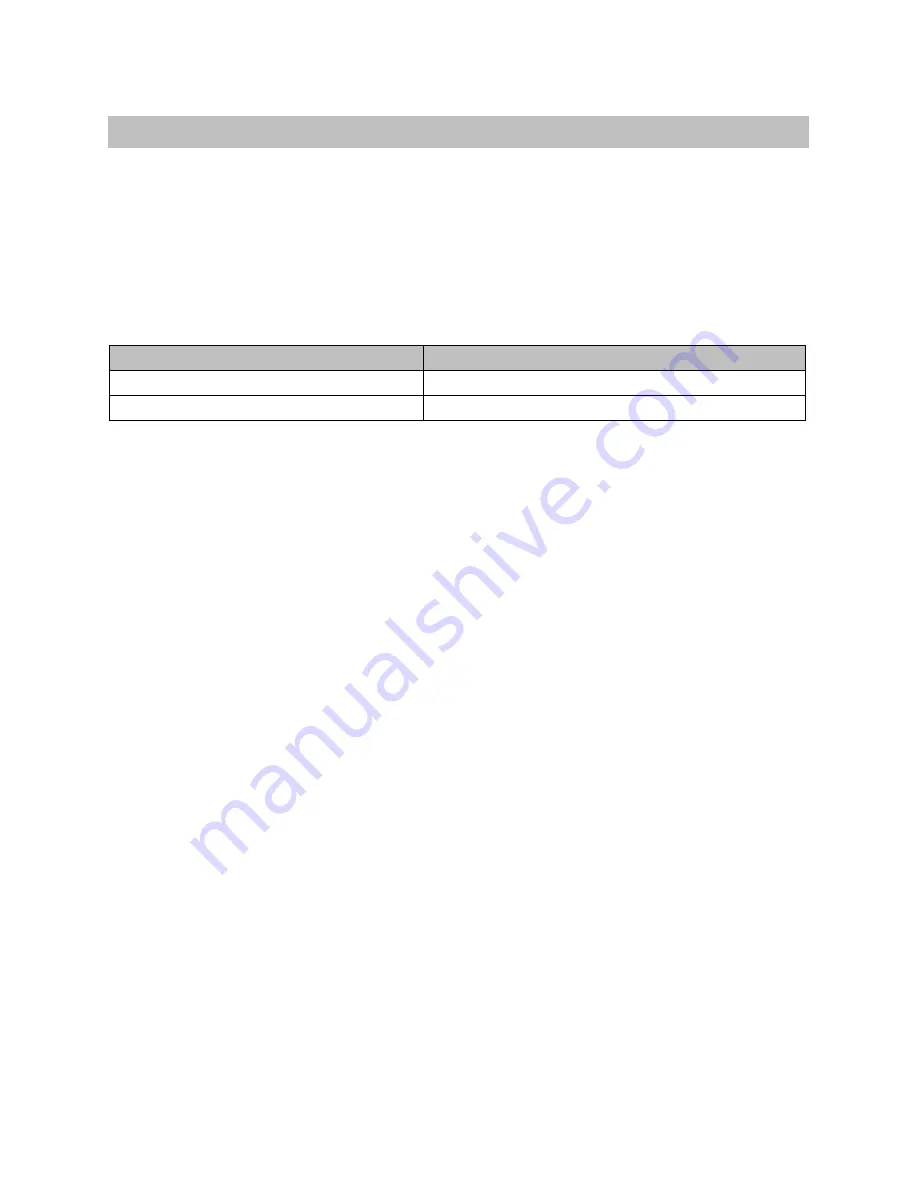

Model Number

Capacity

091-EPWS-1

10,000 Grains

091-EPWS-2

22,000 Grains