20

CONDENSATE DISCHARGE PIPING. If installing

a condensate discharge line, the piping must

be at least one size larger than the connection,

as short and direct as possible, secured tightly

and routed to a suitable drain point or waste

container. Condensate must be disposed of in

accordance with local, state, and federal laws

and regulations.

WARNING: If an aftercooler, check valve,

block valve, or any other restriction is added

to the compressor discharge, install a prop-

erlysized ASME approved safety/relief valve

between the compressor discharge and the

restriction.

INSTALLING ELECTRICAL WIRING (ELECTRIC

MOTOR UNITS)

WARNING: Electrical installation and ser-

vice should be performed by a qualified elec-

trician who is familiar with all applicable local,

state and federal laws and regulations.

GENERAL. The motor rating, as shown on the

motor nameplate, and the power supply must

have compatible voltage, phase and hertz

characteristics.

MAGNETIC STARTER. If the motor installed on

your unit has a motor reset button, it does not

require a magnetic starter. If the motor does

not have this button and the unit does not

have a factory-installed starter, install a mag-

netic starter with thermal overload protection.

Follow the manufacturer’s instructions for in-

stallation. URREA cannot accept responsibility

for damages arising from failure to provide

adequate motor protection.

FUSES. Refer to the NEC to determine the

proper fuse or circuit breaker rating required.

When selecting fuses, remember the momen-

tary starting current of an electric motor is

greater than its full load current. Time-delay or

“slow-blow” fuses are recommended.

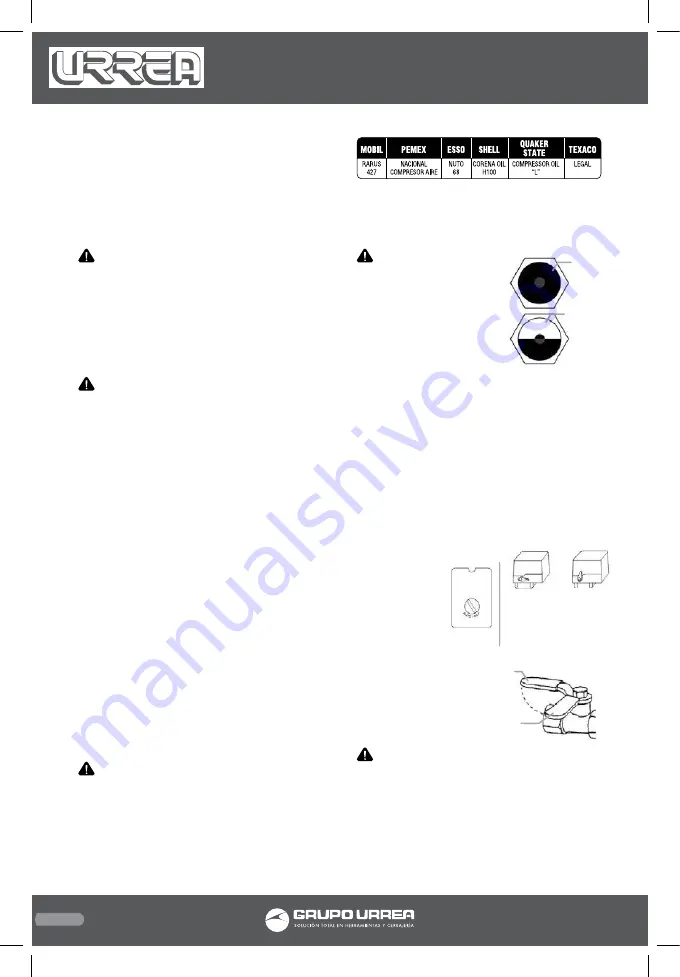

COMPRESSOR LUBRICATION

CAUTION: Do not operate without lubri-

cant or with inadequate lubricant. URREA is

not responsible for compressor failure caused

by inadequate lubrication.

SYNTHETIC COMPRESSOR LUBRICANT.

NOTE: For compressors with this feature, use

two stages oil with viscosity of 70; DO NOT use

automotive oil.

FILLING PROCEDURES:

1. Unscrew and remove the oil fill plug.

2. Fill the crankcase with lubricant.

3. Replace the oil fill plug HAND TIGHT ONLY.

CAUTION: Do not re-

move the oil fill plug while

the compressor is running.

Refer to the following ta-

ble for crankcase capacity.

Use one of the following

methods illustrated to de-

termine when the crank-

case is full.

START-UP (ELECTRIC MOTOR DRIVEN MODELS)

1. Close the service valve.

2. Release any remaining tank pressure by

slowly opening the manual drain valve.

3. Close the manual drain valve and apply pow-

er to the compressor.

If the pressure switch is equipped with an “ON/

AUTO-OFF” lever, flip the switch to the “ON/

AUTO” position. If the unit is equipped with

a control panel “ON/OFF” switch, move the

switch to the “ON” position.

Typical Pressure

Switch

4. Slowly open the service valve.

Typical Service Valve

(A = Open, B = Closed)

CAUTION: Unusual noise or vibration indi-

cates a problem. Do not continue to operate

until you identify and correct the source of the

problem.

COMPRESSOR CONTROLS

ADJUSTMENT PROCEDURE. Select either auto-

matic start and stop control or constant speed

control by adjusting the knob on the auxiliary

ON/AUTO

OFF

ON/AUTO

OFF

A

B

Over-

filled

Optimal

quantity

COMP95XX manual.indd 20

23/06/15 14:27