Maintenance

Section

4-24

AB38 Work Platform

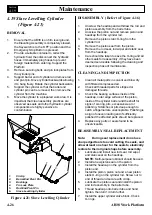

4.17

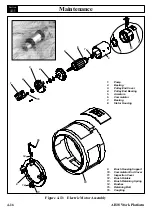

CLEANING AND INSPECTION

1.

Clean all metal parts in solvent and blow dry

with filtered compressed air.

2.

Check all threaded parts for stripped or

damaged threads.

3.

Check the bearing surfaces inside of the

headcap, outer edge surface of the rod &piston

assembly or inside of the cylinder barrel and the

shaft for signs of scoring, pits, excessive wear

or polishing. Scratches or pits deep enough to

catch a fingernail are unacceptable. Polishing is

a sign of uneven loading and if sufficiently

polished the affected parts should be replaced.

4.

Replace any parts or seals found to be

unserviceable.

REASSEMBLY/SEAL REPLACEMENT

Note:

During seal replacement do not use

sharp edged tools to avoid cutting the seals, and

allow at least one hour for the seals to elastically

restore to their original shape before assembly.

1.

Lubricate and install new rod seal, rod wiper

and static seal on the headcap.

NOTE:

Multi-purpose lubricant should be used.

2.

Install a new piston seal on the piston.

3.

Install the headcap on one end of the cylinder

barrel.

4.

Lubricate the piston seal and install the rod &

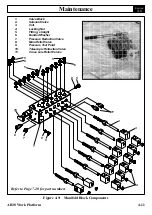

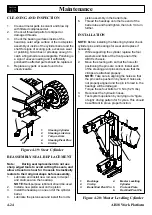

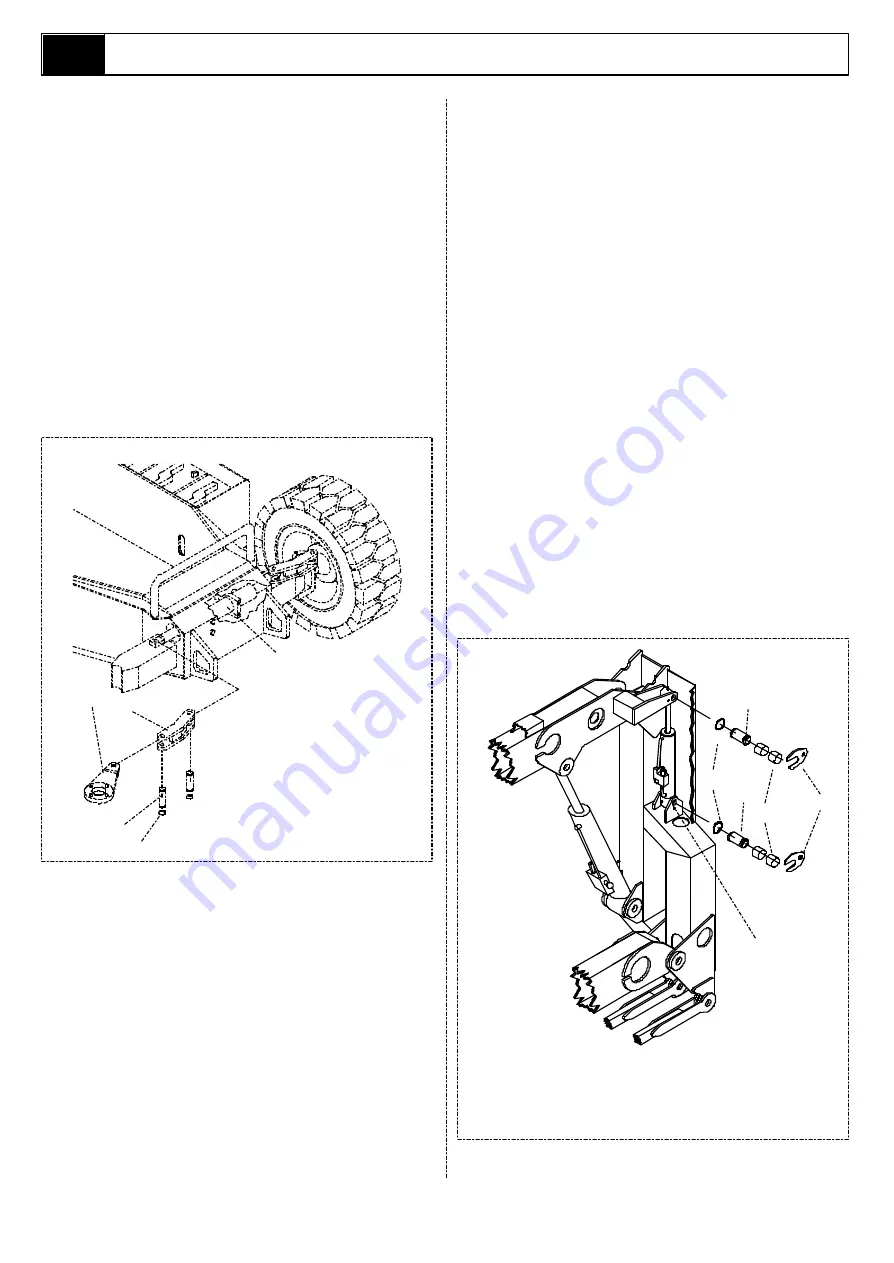

Figure 4-19: Steer Cylinder

piston assembly in the barrel tube.

6.

Thread the headcap onto the free end of the

barrel tube and hand tighten, then turn 1/4 turn

further.

INSTALLATION

NOTE:

Before installing the Steering Cylinder check

cylinder pins and bearings for wear and replace if

necessary.

1.

While supporting the cylinder replace the four

washers and bolts at the front panel of the

AB38’s chassis.

2.

Move the steering arm so that the holes for

positioning the pins are correct. Install each

of the steering pivot pins and ensure that the

circlips are attached properly.

NOTE:

Take care in aligning the holes so that

the pin can be pushed in by hand. If holes are

not properly aligned and the pin is forced in, the

bearings will be damaged.

Torque these four bolts to 70 Nm (52 ft. lbs).

3.

Reconnect the hydraulic hoses.

4.

Test system operation by carrying out a ‘figure

of eight’ driving pattern for 5 cycles. This should

be sufficient to prove proper function.

Figure 4-20: Master Levelling Cylinder

1.

Steering Cylinder

2.

Steering Link Arm

3.

Torque Arms

4.

Steering Pivot Pins

5.

Circlip

3

2

4

5

1

1.

Bushings

2.

Circlip

3.

Barrel End Pivot Pin

2

3

5

4

6

4.

Master Levelling

Cylinder

5.

Pin Lock Plate

6.

Rod End Pivot Pin

1

Содержание AB38

Страница 2: ...ii AB38 Work Platform NOTES...

Страница 4: ...ii AB38 Work Platform NOTES...

Страница 6: ...iv AB38 Work Platform NOTES Foreword...

Страница 10: ...Contents Section IV AB38 Work Platform i NOTES...

Страница 14: ...Introduction Specifications Section 1 4 AB38 Work Platform NOTES 1 3...

Страница 17: ...Machine Preparation Section 2 3 AB38 Work Platform NOTES 2 7...

Страница 18: ...Machine Preparation Section 2 4 AB38 Work Platform 2 7 NOTES...

Страница 29: ...Operation Section 3 11 AB38 Work Platform NOTES 3 5...

Страница 30: ...Operation Section 3 12 AB38 Work Platform NOTES 3 5...

Страница 59: ...Maintenance Section 4 29 AB38 Work Platform NOTES 4 21...

Страница 60: ...Maintenance Section 4 30 AB38 Work Platform NOTES 4 21...

Страница 66: ...Troubleshooting Section 5 6 AB38 Work Platform 5 7 NOTES...

Страница 68: ...Schematics Section 6 2 AB38 Work Platform NOTES 6 0...

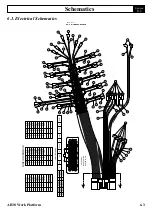

Страница 71: ...Schematics Section 6 5 AB38 Work Platform 6 1 6 1 Electrical Schematics J1 Harness Connections TOP VIEW...

Страница 72: ...Schematics Section 6 6 AB38 Work Platform 6 1 NOTES...

Страница 73: ...Electrical Schematic Schematics 6 7 AB38 Work Platform Section 6 1...

Страница 74: ...Electrical Schematic Schematics 6 8 AB38 Work Platform Section 6 1 TOP VIEW...

Страница 76: ...Schematics Section 6 10 AB38 Work Platform NOTES 6 2...

Страница 78: ...Section 6 2 6 12 AB38 Work Platform Schematics NOTES...

Страница 81: ...Illustrated Parts Breakdown Section 7 3 AB38 Work Platform 7 2...

Страница 83: ...Illustrated Parts Breakdown Section 7 5 AB38 Work Platform 7 2...

Страница 85: ...Illustrated Parts Breakdown Section 7 7 AB38 Work Platform 7 2...

Страница 87: ...Illustrated Parts Breakdown Section 7 9 AB38 Work Platform 7 2...

Страница 89: ...Illustrated Parts Breakdown Section 7 11 AB38 Work Platform 7 2 22...

Страница 91: ...Illustrated Parts Breakdown Section 7 13 AB38 Work Platform 7 2...

Страница 93: ...Illustrated Parts Breakdown Section 7 15 AB38 Work Platform 7 2...

Страница 95: ...Illustrated Parts Breakdown Section 7 17 AB38 Work Platform 7 2...

Страница 97: ...Illustrated Parts Breakdown Section 7 19 AB38 Work Platform 7 2...

Страница 99: ...Illustrated Parts Breakdown Section 7 21 AB38 Work Platform 7 2...

Страница 101: ...Illustrated Parts Breakdown Section 7 23 AB38 Work Platform 7 2...

Страница 103: ...Illustrated Parts Breakdown Section 7 25 AB38 Work Platform 7 2...

Страница 105: ...Illustrated Parts Breakdown Section 7 27 AB38 Work Platform 7 2...

Страница 107: ...Illustrated Parts Breakdown Section 7 29 AB38 Work Platform 7 2...

Страница 109: ...Illustrated Parts Breakdown Section 7 31 AB38 Work Platform 7 2...

Страница 111: ...Illustrated Parts Breakdown Section 7 33 AB38 Work Platform 7 2...

Страница 113: ...Illustrated Parts Breakdown Section 7 35 AB38 Work Platform 7 2...

Страница 115: ...Illustrated Parts Breakdown Section 7 37 AB38 Work Platform 7 2...

Страница 117: ...Illustrated Parts Breakdown Section 7 39 AB38 Work Platform 7 2...

Страница 119: ...Illustrated Parts Breakdown Section 7 41 AB38 Work Platform 7 2 8 9...

Страница 121: ...Illustrated Parts Breakdown Section 7 43 AB38 Work Platform 7 2...

Страница 123: ...Illustrated Parts Breakdown Section 7 45 AB38 Work Platform 7 2...

Страница 125: ...Illustrated Parts Breakdown Section 7 47 AB38 Work Platform 7 2...

Страница 127: ...Illustrated Parts Breakdown Section 7 49 AB38 Work Platform 7 2...

Страница 131: ...Illustrated Parts Breakdown Section 7 53 AB38 Work Platform 7 2 NOTES...

Страница 133: ...Technician s Print AB38 Work Platform Electrical Schematic...