P a g e

| 10

Manuel Fuel Feeding, ÜKY/W Hot Water Boiler User Manual

Warning about the water level:

After the first water is pressed into the system, the minimum water level must be marked on the

hydrometer. Water level should be checked on a daily basis and water should be added to the

installation when it falls below the minimum value.

Adding fresh water to the installation should only be carried out when the installation is cold.

Warning of corrosion in installation:

UNMAK boilers are extremely resistant to corrosion.

However, all iron-based components in the heating

installation (including installation pipes and radiators)

must be protected against corrosion. Oxygen in the

heating water causes oxidation of the iron surfaces

resulting in rust and thus loss of material.

During the initial filling of the installation, the

accumulated air must be evacuated. Usually, if the

necessary measures are taken after the first filling,

there is no damage caused by the oxygen in the water.

Oxidation is mostly caused by oxygen which is involved

in the heating water during operation.

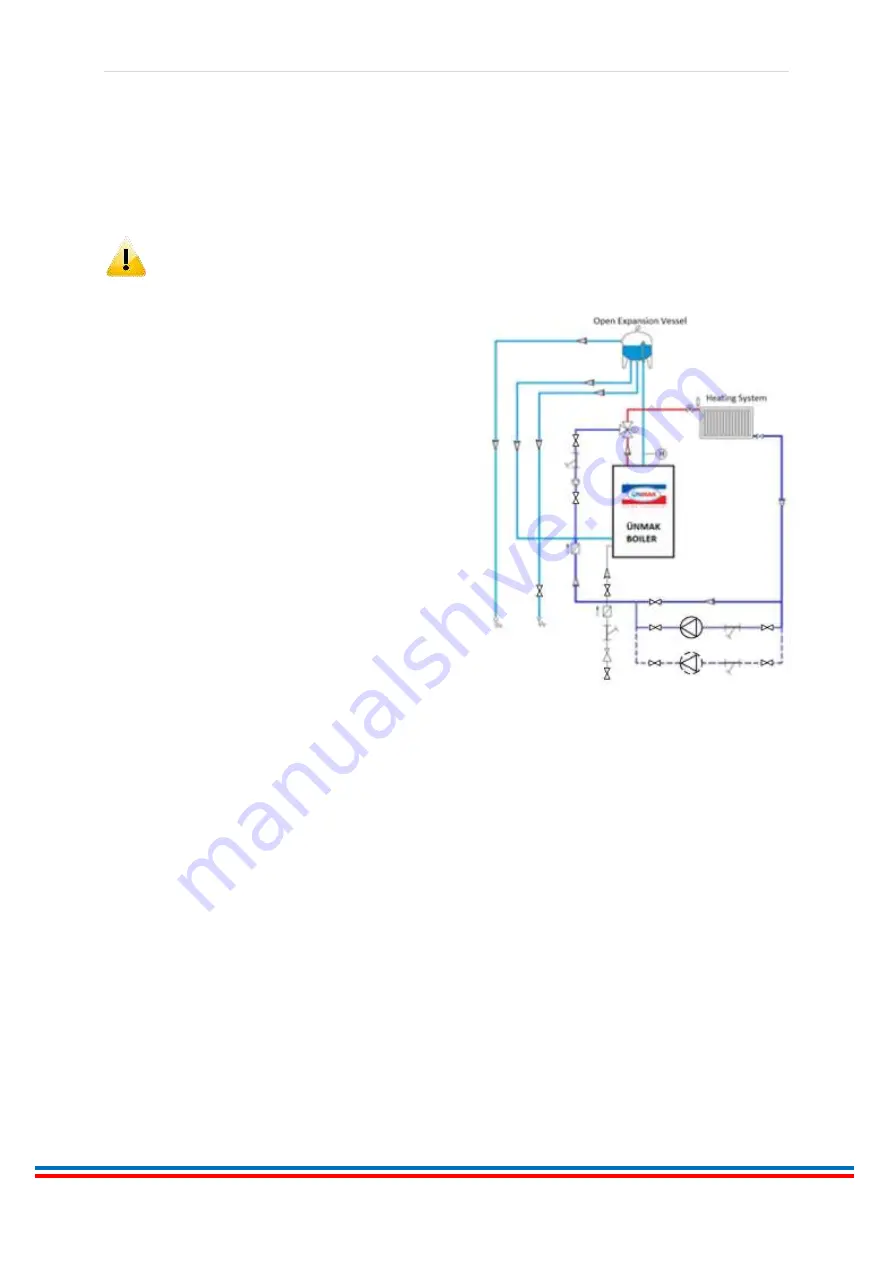

Warning against frost protection:

The heating installation must be completely isolated. Outdoor parts of the installation should be

isolated more than the interior. If operating with an open expansion tank, the return and return pipes

to the expansion line must be isolated or even the expansion tank must be isolated.

Considerations in new installations:

To minimize the addition of fresh water system design and sizing should be done correctly. None of

the materials used in the installation must have a gas permeability. A maximum of 50 micron filters of

synthetic or metal porous must be placed on the fresh water splicing line.

Considerations for heating connected to old installations:

A long-term heating system produces a protective layer (black magnetite) on metal surfaces in contact

with water. When a new boiler is installed in the old system, the clean surfaces of the boiler will be the