19

ADJUSTING THE TRANSFER ROLL TO DIE FACE CONTACT PRESSURE

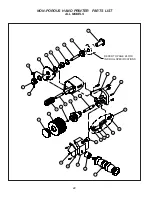

FIGURE 37

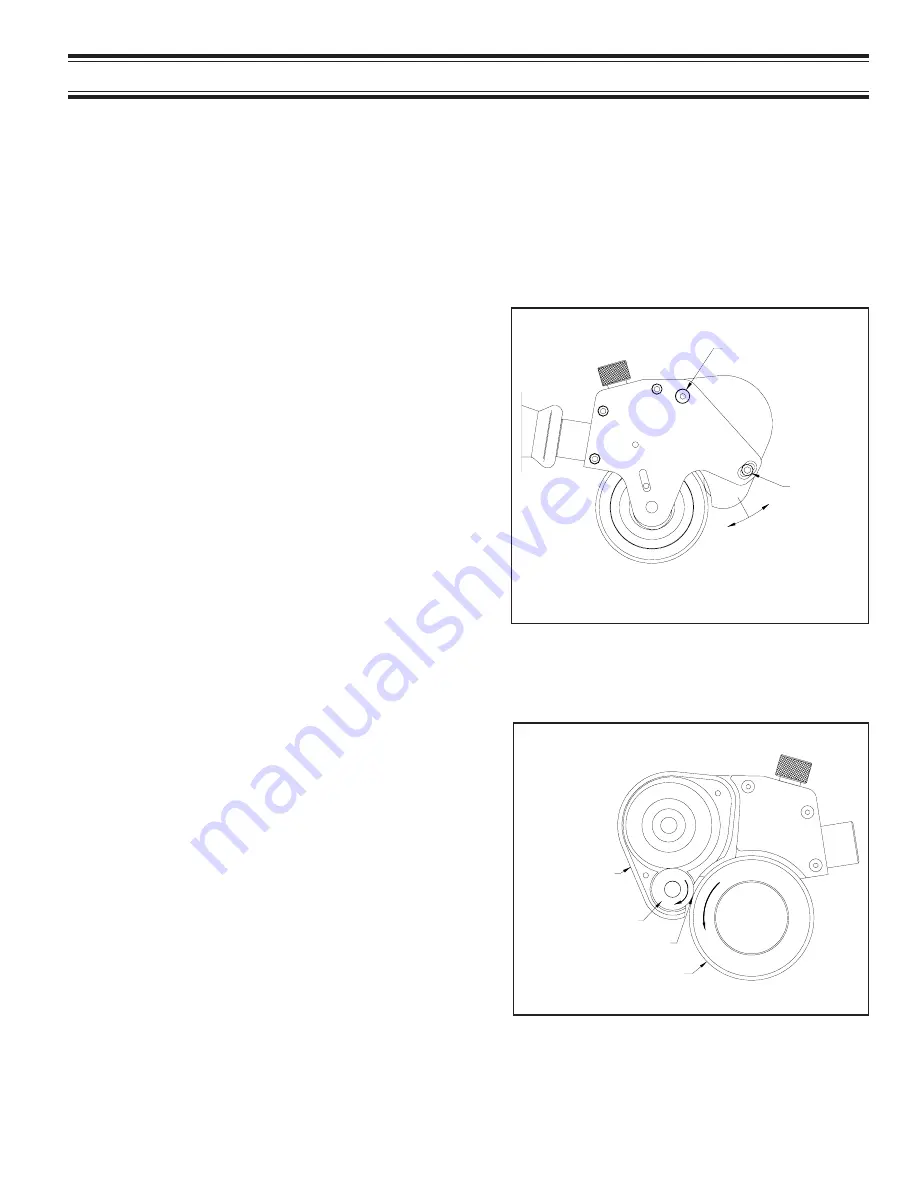

FIGURE 38

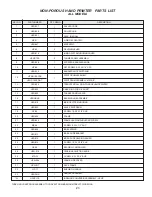

If for any reason, it becomes necessary to disassemble the entire printer, use the exploded parts diagram in the

back of this manual for reference during reassembly. There are only 2 critical assembly instructions which

require particular attention as follows:

When reinstalling the inking system housing on the

printer frame, first install Pivot Screw “A”. The Pivot

Screw should be snug but not tight. Install Adjusting

Screw “B” but leave it loose. With the Transfer Roll

fully seated on it’s axle and the Print Drum properly

installed, pivot the Inking System Housing towards the

print drum until the surface of the Transfer Roll makes

positive contact with the Bearer rings on the Print Drum.

The contact pressure should be just enough to posi-

tively drive the Transfer Roll when the Print Drum is

rotated. When the proper position has been reached,

tighten Screw “B” and then Screw “A”. Rotate the Print

Drum to ensure the Transfer Roll is rotating.

In operation, when the Print Drum is rotating, the rubber

Bearer rings on the Print Drum must positively drive the

Transfer Roll. The amount of engagement pressure

exerted at the contact point between these two compo-

nents is adjustable by moving the position of the Inking

System Housing. If the contact pressure is too light,

the Transfer Roll will not rotate and no ink transfer will

occur. If the contact pressure is excessive, it will cause

too much drag on the Print Drum and the Index Mecha-

nism will not operate properly.

ADJUSTING

SCREW “B”

PIVOT SCREW “A”

ADJUST FOR

LIGHT CONTACT

INKING SYSTEM

HOUSING

TRANSFER ROLL

CONTACT POINT

BEARER RING

CODER REASSEMBLY INSTRUCTIONS

Содержание HPNP-100

Страница 25: ...25 ...