USSC

21

FUEL ADDITIVE

Chicken Scratch for my Corn Burner?

Yes - Crazy as it may sound, ground Oyster Shells, (calcium carbonate) same as fed to chickens, is the ideal additive to

promote clean burning, especially when the Corn Fuel is extra high in starch. And it’s available at your local Feed and Seed.

The “average” mixture is 1/2 pound of Oyster Shells (about 2 handfuls) to 60 pound of Corn, a full hopper. IF the “fingers”

on your agitator (stirrer or rouser) have a noticeable buildup of “clinkers” or stubborn deposits, you have either a high starch

fuel OR are burning with too much air for proper combustion and are reaching the “fusion” temperature of the Potassium

and/or Starch in the Corn. You need Oyster Shells - and maybe more than a couple handfuls.

If you notice a heavy accumulation of “whitish powder” in your burn pot, reduce the amount of Oyster Shell Additive.

Remember, using this additive- as necessary - promotes efficiency (higher heat output), reduces maintenance, clinkers and

ash content.

The mixing of hardwood pellets with corn also reduces clinker build-up. In addition, pellets will help wetter corn burn.

WARNING

These automatic safety features must not be bypassed

AUTOMATIC SAFETY FEATURES

•

•

Power Outage

During a power outage, the stove will shut down. It will not automatically restart when the power returns,

unless the

stove is still above the proper operating temperature and a flame still exist in the burnpot.

Overheating

A high temperature switch will automatically shut down the stove if it overheats. The stove will need to be manually relit.

Allow 45 minutes before relighting.

Shut down the stove as directed in the operating instructions. Allow the stove to cool to room temperature. Remove the

small clean-out slides in the lower corners of the firebox. Tap the sides of the burn chamber with a wooden stick. Do not

tap the firewall behind the burn box as it may damage the ceramic firebrick. Scrape the fly ash from the clean-out

chambers toward the front of the burn chamber. Remove the fly ash from the burn chamber and replace the clean-outs.

Remove the ash pan and dump the ash into a metal container.

Cleaning of the exhaust system will depend upon the ash and debris content of your fuel. If your fuel has a high ash

content and/or significant debris in it, your exhaust system will require weekly cleaning. Cleaner fuels will allow for

monthly cleaning of the exhaust system. Remove the exhaust pipe from the back of your stove and remove any ash that

may have collected in the pipes. Replace the pipes to the stove and seal with high temperature seal tape. If you have

installed proper clean out tees you will not have to take the chimney sections apart.

REMEMBER: A clean unit burns efficiently and will remain trouble free!

Weekly Maintenance

SPRING CLEANING:

When the heating season is over make sure that you clean out all of the fuel in the hopper, firebox area, ash pan and firepot

area. Corn and any ash can accumulate moisture over the summer months causing the unit to rust and the fuel to mold.

Corn left in the unit will attract mice and can cause internal wiring and insulation damage.

When the unit is cleaned out, take the venting apart, clean out the fly ash, rinse the venting out with a water hose and let dry,

take the draft fan off and clean, clean out all areas such as back heat exchanger and lubricate the auger, auger tube, firepot

area, agitator shaft and bearings and hopper area with a light oil (something like Pam cooking oil works great to coat the

inside of the unit and the moving parts). Clean the glass, doors and outer cabinet so that you are ready for the next heating

season. Use of a wet/dry vacuum makes all cleaning easier.

•

•

•

Содержание American Harvest 6039I

Страница 5: ...USSC 5 COMPONENT LOCATION...

Страница 9: ...USSC 9 CLEARANCES TO COMBUSTIBLES 6039I...

Страница 25: ...USSC 25 WIRING DIAGRAM...

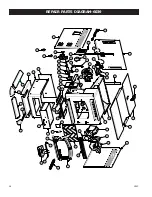

Страница 26: ...26 USSC REPAIR PARTS DIAGRAM 6039...

Страница 31: ...USSC 31 Notes...