20

USSC

SPECIAL CLEANING/OPERATIONAL

INSTRUCTIONS:

After cleaning or when operating the

stove, you need to make sure that

“both” clean-outs are in their proper

position. If left out or placed incor-

rectly, the combustion air is effected

greatly and the stove will not burn

properly.

Also, make sure that the ash dumps

on each side of the damper are pushed

in completely. This will also effect the

combustion air.

MAINTENANCE INSTRUCTIONS

•

•

•

•

•

•

Surfaces on the front of the stove will be extremely hot during operation. Always wear heat resistant gloves

to perform periodic maintenance.

Using a wooden stick, tap the side heat exchangers that are located on the left and right sides of the firebox. When you

open the door, they are located directly inside to the left and right. When you tap the sides with the wooden stick the

loose fly ash will drop out of these holes.

Inspect inside stove for excessive ash build up. You will learn some fuels produce more ash than others. If excessive,

remove the inside ash clean-outs. Once you have cleaned out the ashes, replace the clean-outs. Depending on your fuel

and use, these clean-outs may be removed only weekly.

If clinkers develops in the firepot,clean thoroughly. You may have to do this once or twice a day depending on the

moisture content of the corn. If this is not cleaned out, it could cause the agitator to jam. USSC highly recommends an

additive (see Fuel Additive) be added to your corn to eliminate these clinkers. Contact your local dealer for availability

and cost. You will need this additive if the agitator “fingers” develop an accumulation or build-up.

The clinkers on the agitator and burnpot are easily removed when soaked in warm water for 10 minutes.

The ash pan (especially the model 6039I) should be cleaned out on a daily basis or as needed depending ash build-up.

Daily Maintenance

Soot and Flyash - Formation and Need for Removal

The products of combustion will contain small particles of flyash. The flyash will collect in the exhaust venting system and

restrict the flow of flue gases. Incomplete combustion, such as occurs during startup, shutdown, or incorrect operation of

the room heater will lead to some soot formation which will collect in the exhaust venting system. The exhaust venting

system should be inspected at least once per month (of heavy use) to determine if cleaning is necessary. Corn has a high

ash content.

DISPOSAL OF ASHES

Disposal of Ashes

Ashes should be placed in a metal container with a tight fitting lid. The closed container of ashes should be placed on a

noncombustible floor or on the ground, well away from all combustible materials, pending final disposal. If the ashes are

disposed of by burial in soil or otherwise locally dispersed, they should be retained in the closed container until all cinders

have been thoroughly cooled.

Содержание American Harvest 6039I

Страница 5: ...USSC 5 COMPONENT LOCATION...

Страница 9: ...USSC 9 CLEARANCES TO COMBUSTIBLES 6039I...

Страница 25: ...USSC 25 WIRING DIAGRAM...

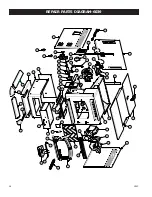

Страница 26: ...26 USSC REPAIR PARTS DIAGRAM 6039...

Страница 31: ...USSC 31 Notes...