IMT120 15

4

Type 820E

To adjust the switch:

❶

Remove the set point adjustment knob and clear cover

from the indicating enclosure (square) to access the pointer

mechanism for adjustment.

❷

Connect test lights or listen for the individual switch clicks

to indicate switch operation.

❸

Move the set point adjustment pointer (red) up the scale

past the indicating pointer (black). This permits checking the

set point by moving the actuating lever upward with a finger,

or tool, simulating thermal assembly movement. Note switch

operation on the test lights.

❹

Loosen adjustment pointer mounting screw “A” and move the

adjustment pointer (red) until it aligns with the indicating pointer

(black) (see Figure 5). When the switch clicks re-tighten the screw.

Type 822E

NOTE:

Type 822E has a single set point adjustment-

knob and adjustment pointer (red) for both switches.

Both switches are standardly factory set together

within 5% of the adjustable set point range. Turning

the set point adjustment knob adjusts both switches

simultaneously, maintaining a fixed separation

between them. To adjust the switches:

❶

Remove the explosion-proof enclosure cover to access the

switches for adjustment.

❷

Remove the set point adjustment knob and clear cover

from the indicating enclosure (square) to access the pointer

mechanism for adjustment.

❸

Connect test lights or listen for the individual switch clicks

to indicate switch operation.

❹

Move the adjustment pointer (red) up the scale past the

indicating pointer (black), actuating both switches, by moving

the actuating lever upward with a finger, or a tool, simulating

thermal assembly movement (see Figure 5). Note switch

operation on the test lights.

❺

The set point of switch #1 is determined by the adjustment

pointer (red). The set point of switch #2 may be adjusted by

up to 25% of the range span below the switch #1 set point

by turning adjustment “D” with a 5/16” open end wrench

(clockwise) to lower the set point. See page 6 for 822E dual

switch adjustment. The set point of switch #2 should never be

set above that of switch #1.

❻

To align the switch #1 adjustment pointer (red) with the

indicating pointer (black), loosen the adjustment pointer mounting

screw “A” and align the adjustment pointer (red) with the indicating

pointer (black), then re-tighten screw “A” (see Figure 5).

NOTE: Indicating Pointer Deflection (820E, 822E)

The indicating pointers will read slightly low when

the bulb temperature is 15° F above the controller

setting. This deflection is normal and repeatable

(approximately 0.5% of scale range on single switch

models) and is due to the transference of the switching

mechanism load to the thermal system. It can be

measured by moving the setting pointer from the high

to the low end of the scale and observing the resultant

indicating pointer deflection.

NOTE:

To adjust the Indicating Pointer (820E, 822E):

❶

Use an accurate test thermometer such as a thermocouple

with its probe mounted directly to the center of the sensing bulb.

❷

Before making any adjustments, allow process temperature

to stabilize; i.e., successive on-off cycles repeated.

❸

Correct any difference between the indicating pointer

(black) and the test thermometer by holding the compensator

with a 5/16” wrench while turning the zero adjustment “C” on

the thermal assembly with a second 5/16” wrench (see Figure

5) until the indicating pointer (black) reads the same value

as the test thermometer. Turning the zero adjustment “C”

clockwise lowers indicated reading.

❹

Compare the process temperature with the set point

adjustment pointer (red).

❺

Loosen the adjustment pointer mounting screw “A” to align

set point adjustment pointer (red) with the indicating pointer

(black), then re-tighten screw “A”.

Correction of Capillary (820E, 822E)

If the length of capillary immersed in the process

differs from the amount immersed (6”, see Mount

-

ing Bulb & Capillary in Part I - Installation) at the

factory calibration bath, a calibration shift will

occur.

The error may be corrected as follows:

❶

Move pointer to the highest temperature setting. Note

indicating scale reading with the head and sensor at room

temperature.

❷

Loosen the two thermal assembly mounting screws.

❸

Re-position the housing index against the calibration on

the instrument case (or skeleton casting) at a rate of 1 division

line per capillary length listed in Figure 6. Move to the left

if capillary is to be added to the process, or to the right if

capillary is to be removed from process.

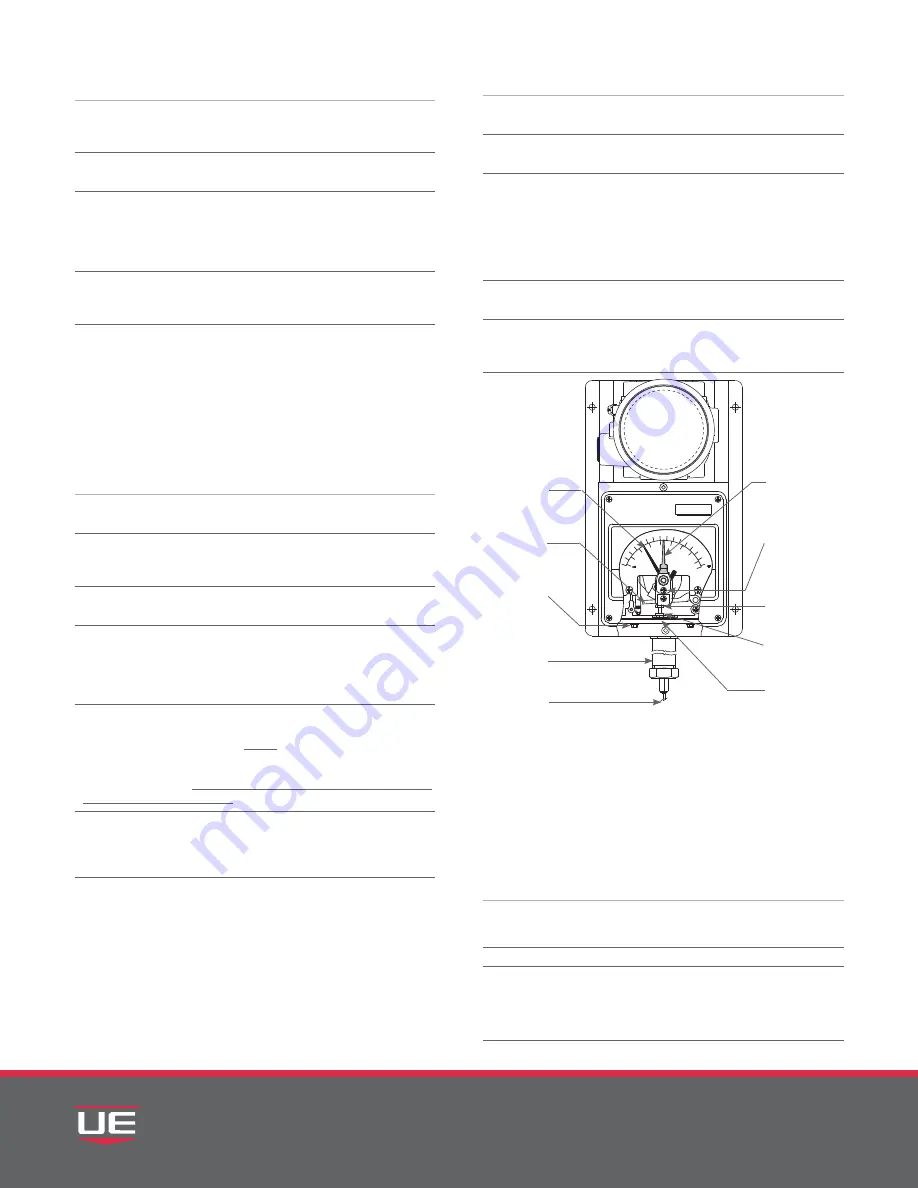

Figure 5: Indicating

Enclosure Internals

CAPILLARY

INDICATING

POINTER

(BLACK)

THERMAL

ASSEMBLY

MOUNTING

SCREWS (2)

THERMAL

ASSEMBLY

HOUSING

INDEX

ADJUSTMENT

POINTER (RED)

ADJUSTMENT

POINTER

MOUNTING

SCREW

(ADJUSTMENT “A”)

ZERO

ADJUSTMENT

“C” 5/16 HEX

COMPENSATOR

ACTIVATING

LEVER